Inverse linear quadratic control method of hot continuous rolling thickness-loop synthetic system

A linear quadratic and comprehensive system technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as uncoordinated optimization of thickness, angle and tension, etc., to avoid solving, simplify control algorithms, and strengthen The effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

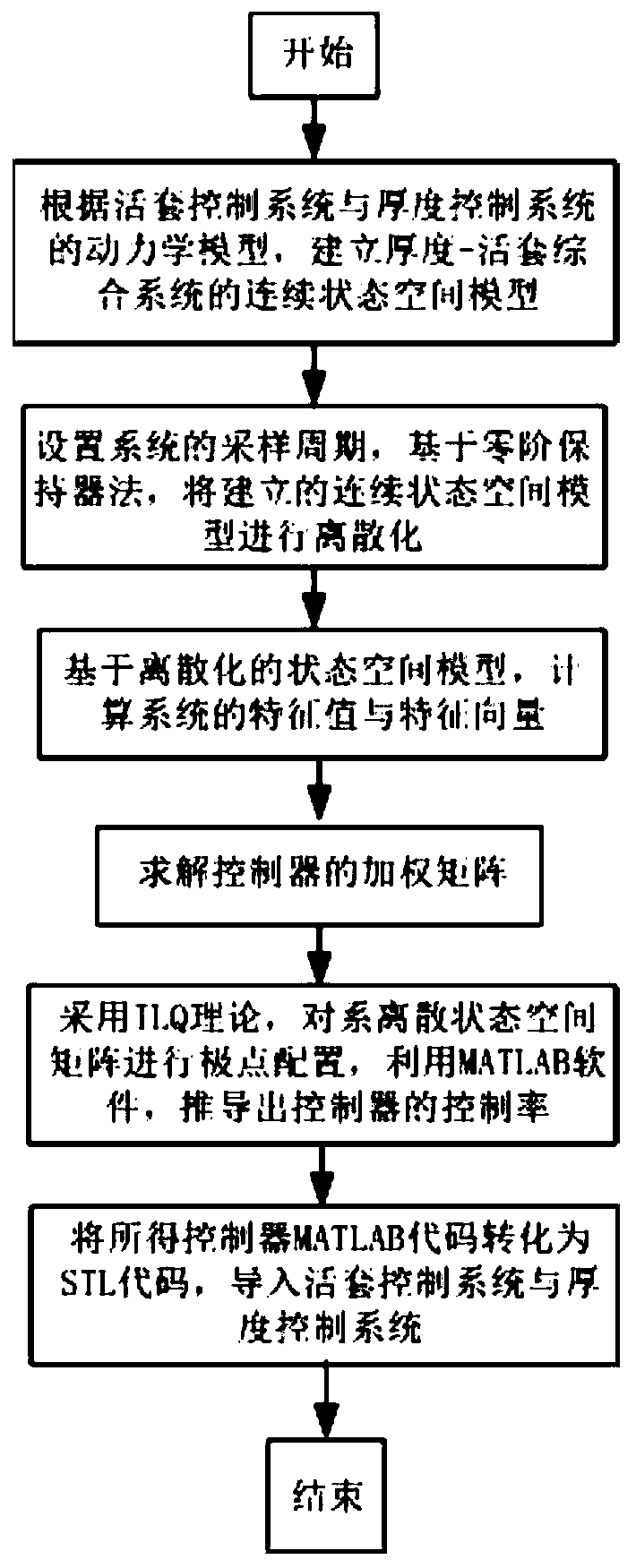

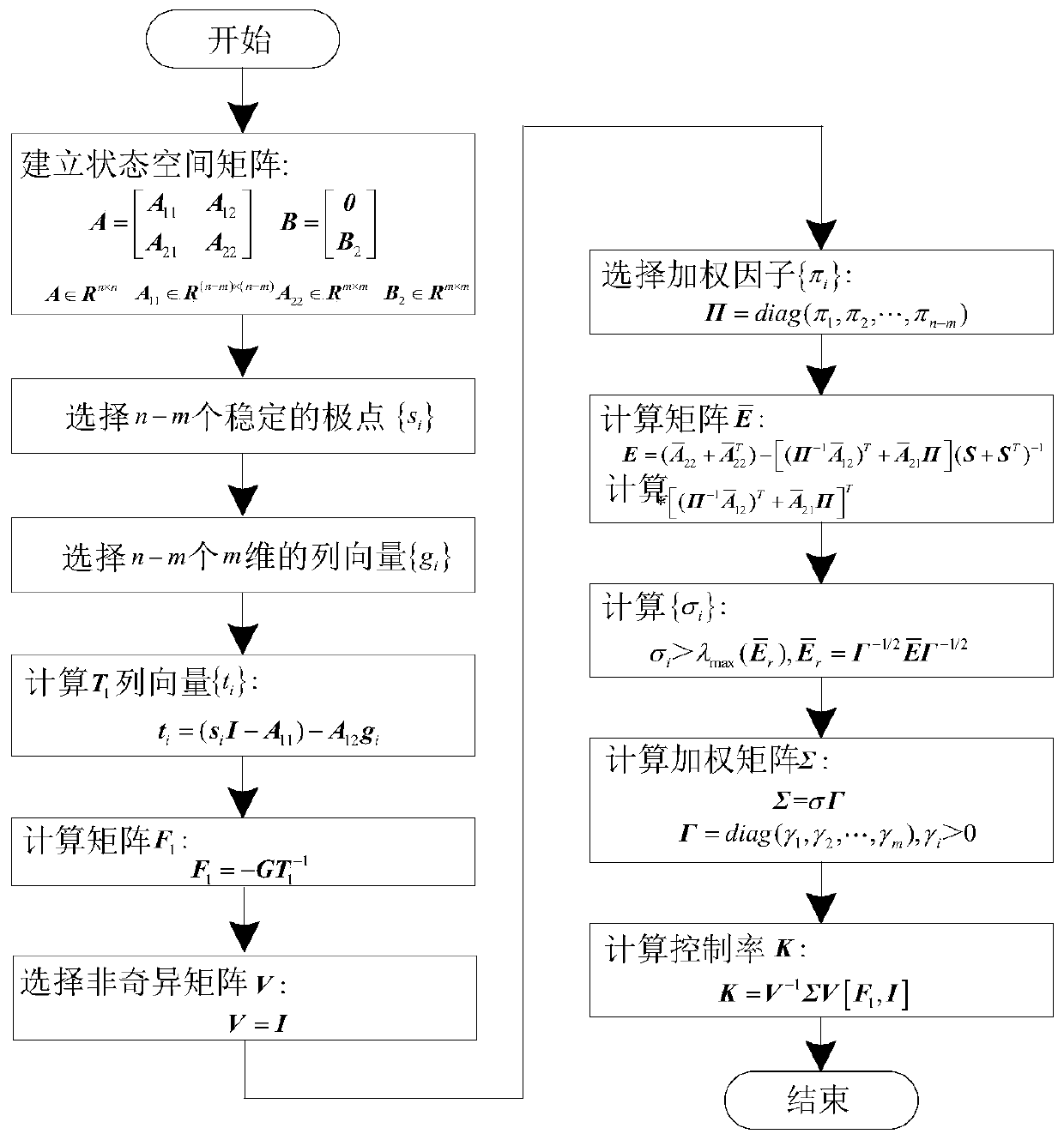

[0048] refer to Figure 1-Figure 4 , an inverse linear quadratic control method for hot continuous rolling thickness-loop integrated system, according to the dynamic model of hot continuous rolling looper control system and thickness control system, the continuous state space of hot continuous rolling thickness-loop integrated system is established model, choose an appropriate sampling period, and adopt the zero-order hold method to discretize the continuous state-space model. Based on the discretized state-space model of the thickness-loop integrated system, the controller of the thickness-loop integrated system is designed using the inverse linear quadratic principle.

[0049] The specific process includes:

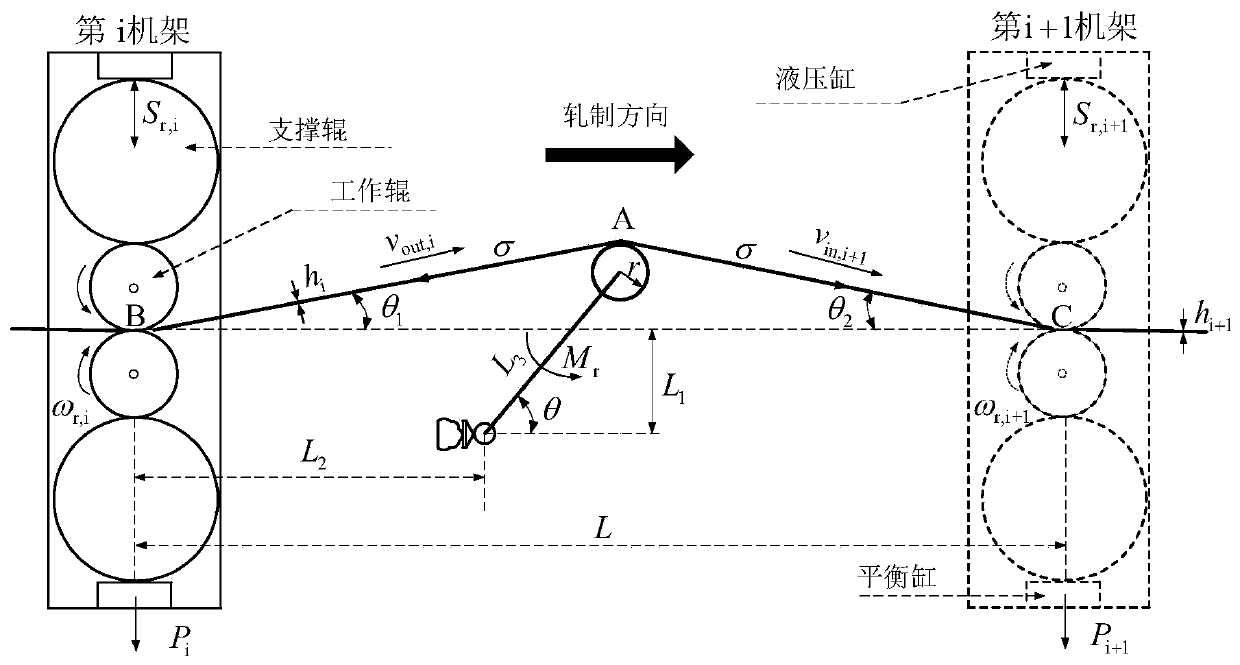

[0050] Step 1: According to the dynamic model of the hot rolling looper control system and the thickness control system, using the state space analysis method, establish the continuous state space model of the thickness-looper integrated system of the i-th rack and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com