Rotating shaft screening mechanism, rotating shaft screening method and rotating shaft assembly device of gearbox

A technology of rotating shafts and detection devices, which is applied in chemical instruments and methods, solid separation, classification, etc., can solve the problems of substandard gearbox performance requirements, affecting gearbox quality, unfavorable gearbox yield, etc., and achieves simple structure and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

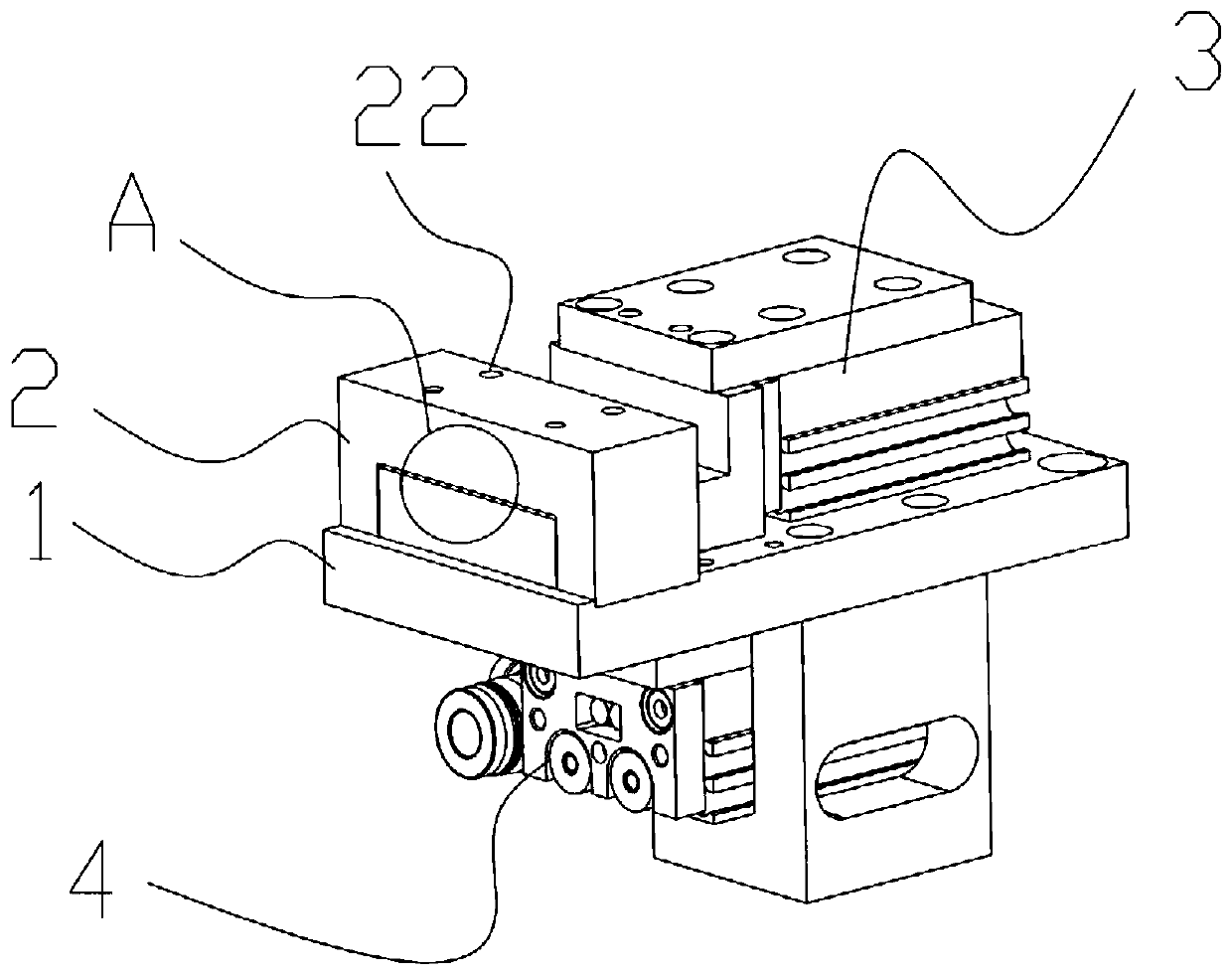

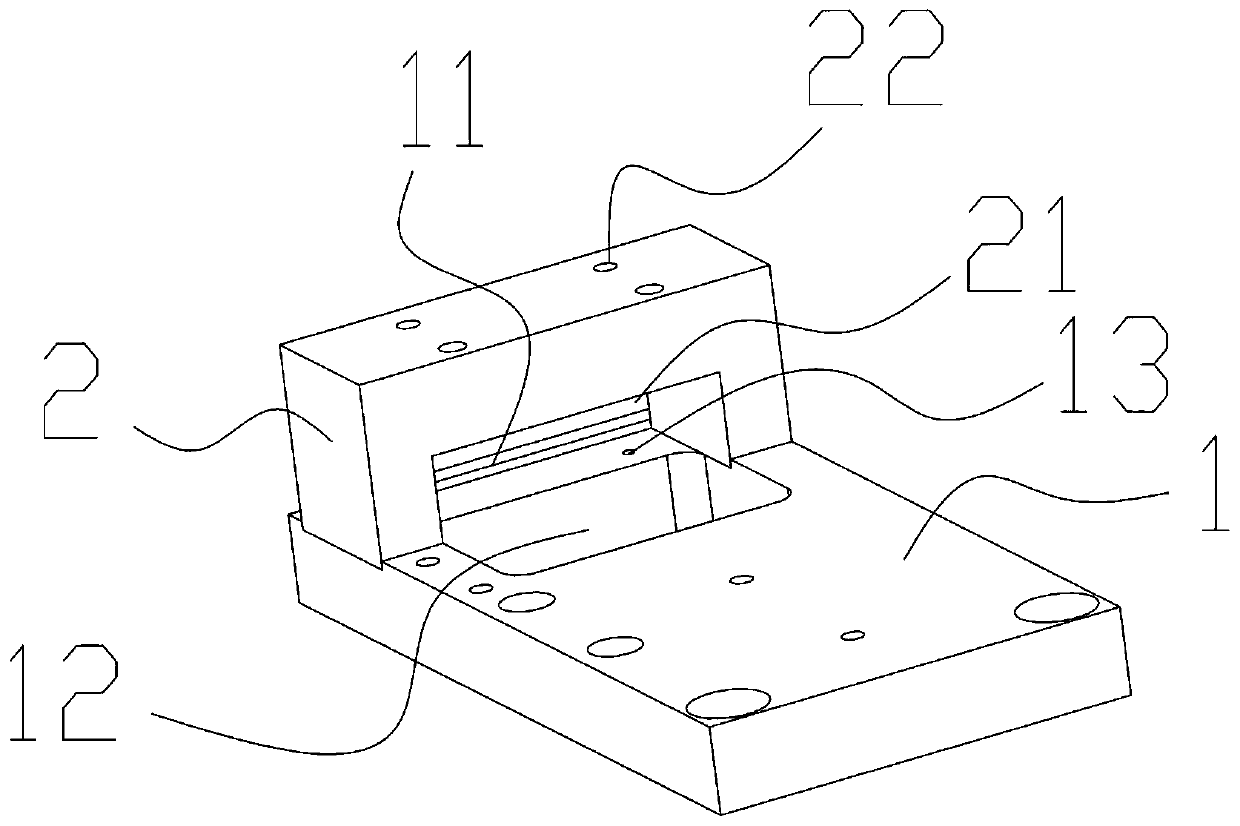

[0036] Such as figure 1 As shown, this embodiment provides a rotating shaft screening mechanism, including a base 1, a screening seat 2 and a screening assembly 3 for screening the rotating shaft are arranged on the top of the base 1, and the bottom of the base 1 is movable. There is a blanking assembly 4 used for blanking unqualified shafts;

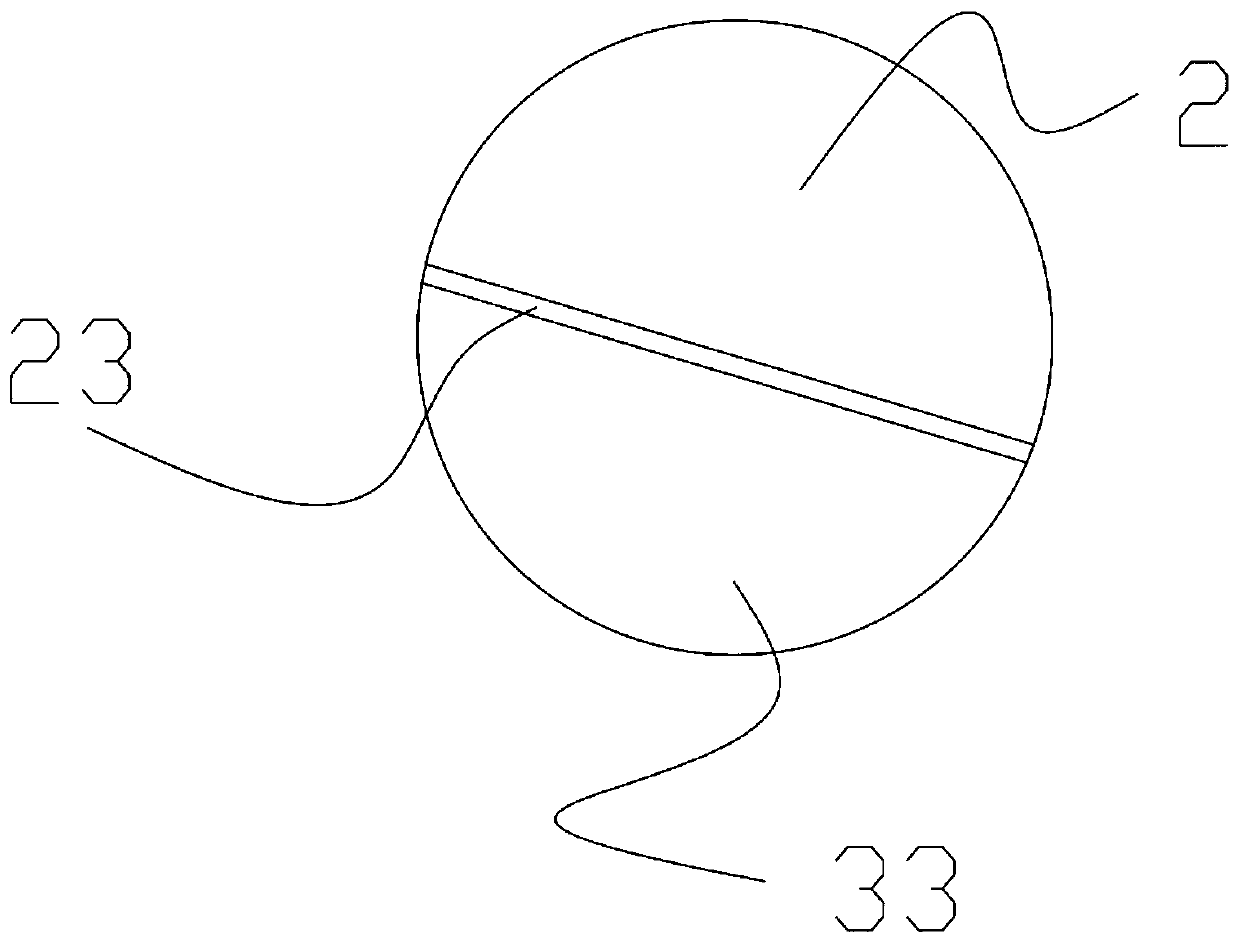

[0037] Such as image 3 As shown, the screening seat 2 is provided with a screening tank 21 and a feeding hole 22, and the feeding hole 22 communicates with the top of the screening tank 21, and the base 1 is provided with a blanking shaft for unloading a qualified rotating shaft. hole 13, the screening assembly 3 is provided with a screening hole 31, and the bottom of the screening hole 31 is covered by the blanking assembly 4.

[0038] When the present invention is in use, the rotating shaft vibrating plate can be communicated with the feeding hole 22 to realize the loading of the rotating shaft through a conduit such as a rubber tu...

Embodiment 2

[0056] This embodiment provides a rotating shaft assembly device for a gearbox, including a body, the body is provided with a feeding mechanism for inputting the gearbox body, a transmission mechanism for transferring the gearbox body, and a rotating shaft for assembling the gearbox body. The body assembly mechanism and the rotating shaft screening mechanism for screening out the qualified rotating shafts, the rotating shaft screening mechanism is the rotating shaft screening mechanism described in Example 1. That is, by installing the rotating shaft screening mechanism described in Embodiment 1 in this embodiment, it is possible to screen out the rotating shafts with a qualified length before assembling the rotating shafts into the gearbox, thereby ensuring that the gearbox produced in this embodiment has a The shaft is never too long or too short to be unusable. It should be noted that the feeding mechanism, transmission mechanism, and assembly mechanism described in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com