Roll shaft manual expanding mould clamp

A tire expansion and fixture technology, applied in the mechanical field, can solve the problems of low clamping efficiency, poor clamping stability, and small application range, and achieve the effects of high clamping efficiency, stability assurance, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

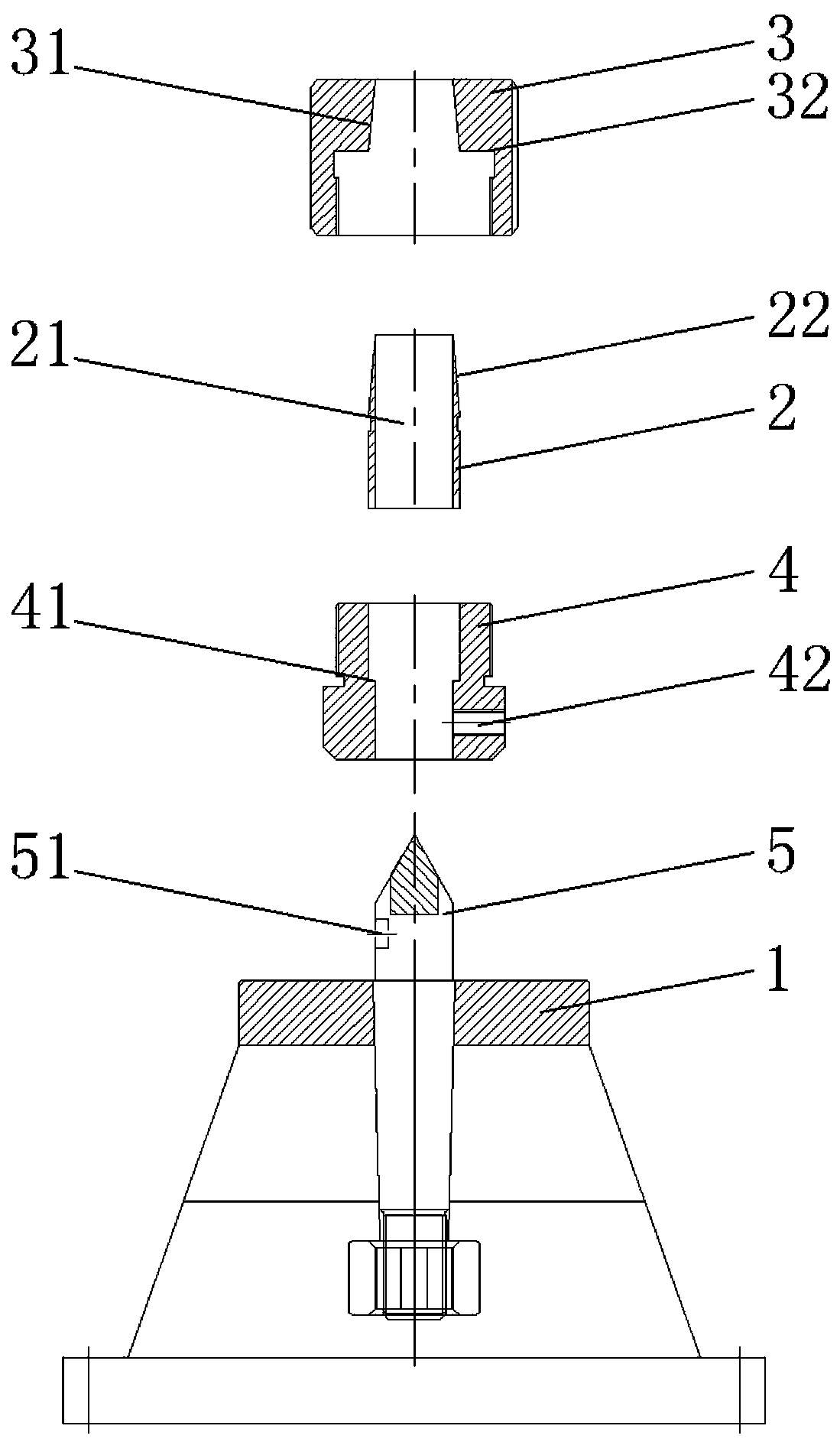

[0017] Such as figure 1 The roller manual tire expansion fixture shown includes a base 1, on which an expansion sleeve 2 for clamping the workpiece is fixed through a positioning structure. The middle part of the expansion sleeve 2 has a shaft hole 21, and the workpiece is passed through the shaft hole 21 , the outside of the expansion sleeve 2 has a conical surface 22 coaxial with the shaft hole 21, and the top of the expansion sleeve 2 is provided with a pressure sleeve 3 for radially shrinking the shaft hole 21 of the expansion sleeve 2. The surface 22 cooperates with the conical hole 31, and when the compression sleeve 3 is pressed down, the axial hole 21 of the expansion sleeve 2 shrinks radially, and the compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com