Al2O3-Ti3AlC2 gradient ceramic and preparation method thereof

A ceramic and gradient technology, applied in the field of Al2O3-Ti3AlC2 gradient ceramics and its preparation, can solve problems such as delamination, local segregation, impact resistance to cold and heat shock, etc., and achieve simple sintering preparation, low cost, and low synthesis cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The technical scheme of the present invention is as follows: the present invention provides a kind of Al 2 o 3 -Ti 3 AlC 2 A preparation method for gradient ceramics, comprising the steps of:

[0036] (1) Raw material crushing: the Al with a purity of 99.95% is crushed by a crushing sample making machine 2 o 3 and Ti with a purity of 98% 3 AlC 2 Broken to the range of 0.1-10μm respectively to form Al 2 o 3 Micron powder and Ti 3 AlC 2 micron powder;

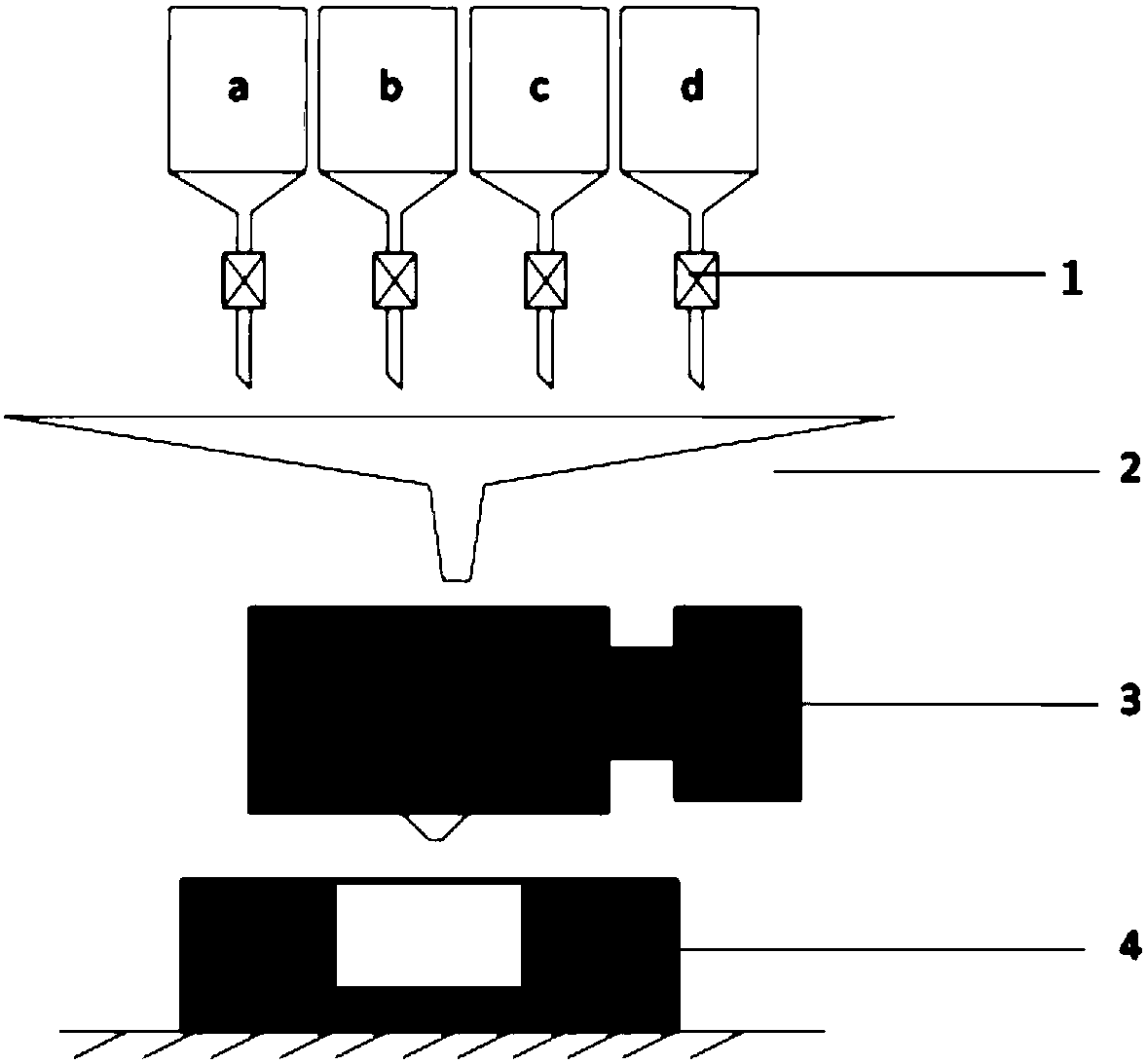

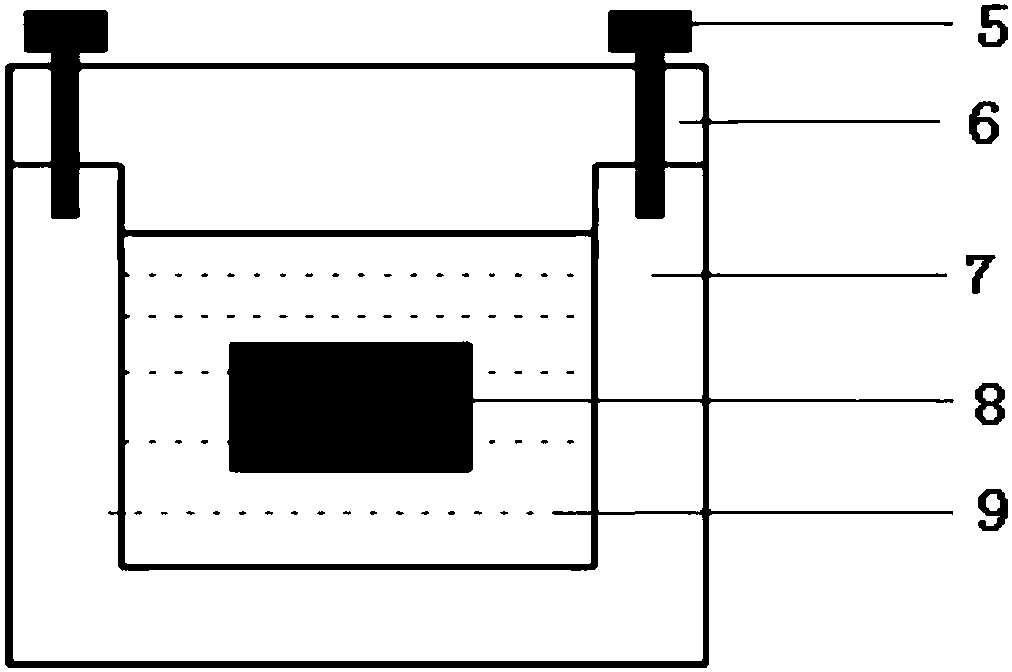

[0037] (2) Mixing injection molding: prepare alumina granulation powder, Al 2 o 3 and Ti 3 AlC 2 Micron powder composite granulation powder with a weight ratio of 1.5-4:1, Al 2 o 3 and Ti 3 AlC 2 Micron powder composite granulation powder and Ti with a weight ratio of 1:1.5-4 3 AlC 2 Granulated powder, respectively marked A, B, C, D, mixed according to the weight ratio of 1:1:1:1, injection molding;

[0038] (3) Molding: The granulated powder mixed for injection molding is molded once by dry pressing, ...

Embodiment 1

[0057] Weigh 320gTi 3 AlC 2 Coarse powder and 60g of high-purity alumina micron powder were put into the pulverizing sample making machine and crushed for 15 minutes to obtain 1-10μm Al 2 o 3 Micron powder and Ti 3 AlC 2 micron powder.

[0058] Take by weighing 160g alumina granulated powder and record it as sample A;

[0059] Weigh the broken Al 2 o 3 and Ti 3 AlC 2 Micron powder 100g and 50g, add 0.6g micron aluminum powder, then add 8g gum arabic and 82g deionized water, mix and stir for 4h, carry out spray granulation, recover 200-250 mesh granulated powder and record it as sample B.

[0060] Also do not weigh the broken Al 2 o 3 and Ti 3 AlC 2 50g and 100g of micron powder, add 1g of micron aluminum powder, then add 8g of gum arabic and 82g of deionized water, mix and stir for 4 hours, carry out spray granulation, recover 200-250 mesh granulated powder and record it as sample C.

[0061] Weigh 160g of Ti 3 AlC 2 Micron crushed powder, add 90g of 10% gum ar...

Embodiment 2

[0065] Weigh 400gTi 3 AlC 2 Coarse powder and 200g of high-purity alumina micron powder were respectively put into a pulverizing sample making machine and crushed for 20 minutes to obtain 0.5-10 μm micron powder.

[0066] Weigh 200g alumina 250-325 mesh granulated powder and record it as sample A;

[0067] Weigh the broken Al 2 o 3 and Ti 3 AlC 2 Micron powder 120g and 30g, add 0.6g micron aluminum powder, then add 10g gum arabic and 90g deionized water, mix and stir for 3h, carry out spray granulation, recover 250-325 mesh granulated powder and record it as sample B;

[0068] Also weigh the broken Al 2 o 3 and Ti 3 AlC 230g and 120g of micron powder, add 1g of micron aluminum powder, then add 8g of gum arabic and 82g of deionized water, mix and stir for 4h, carry out spray granulation, recover 250-325 mesh granulated powder and record it as sample C;

[0069] Weigh 200g of Ti 3 AlC2 micron crushed powder, add 120g aqueous solution containing 15% gum arabic, add 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com