Local repair system and method of drainage pipeline

A technology for partial repair and drainage pipelines, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of inability to accurately locate the damaged point inside the pipeline, complicated operation of partial repair of drainage pipelines, and inability to monitor pipeline repairs in real time, etc. High construction efficiency, small footprint and high curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The present invention aims at the problems of complex operation, low construction efficiency, inability to work with water, inability to accurately locate damaged points inside the pipeline, and inability to monitor pipeline repair conditions in real time in the existing drainage pipeline partial repair operation, and provides a partial drainage pipeline repair system and method .

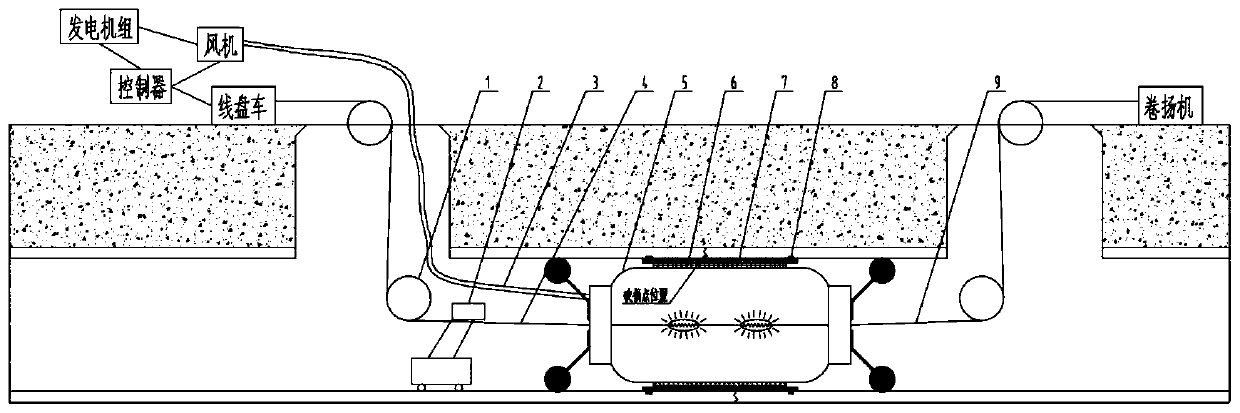

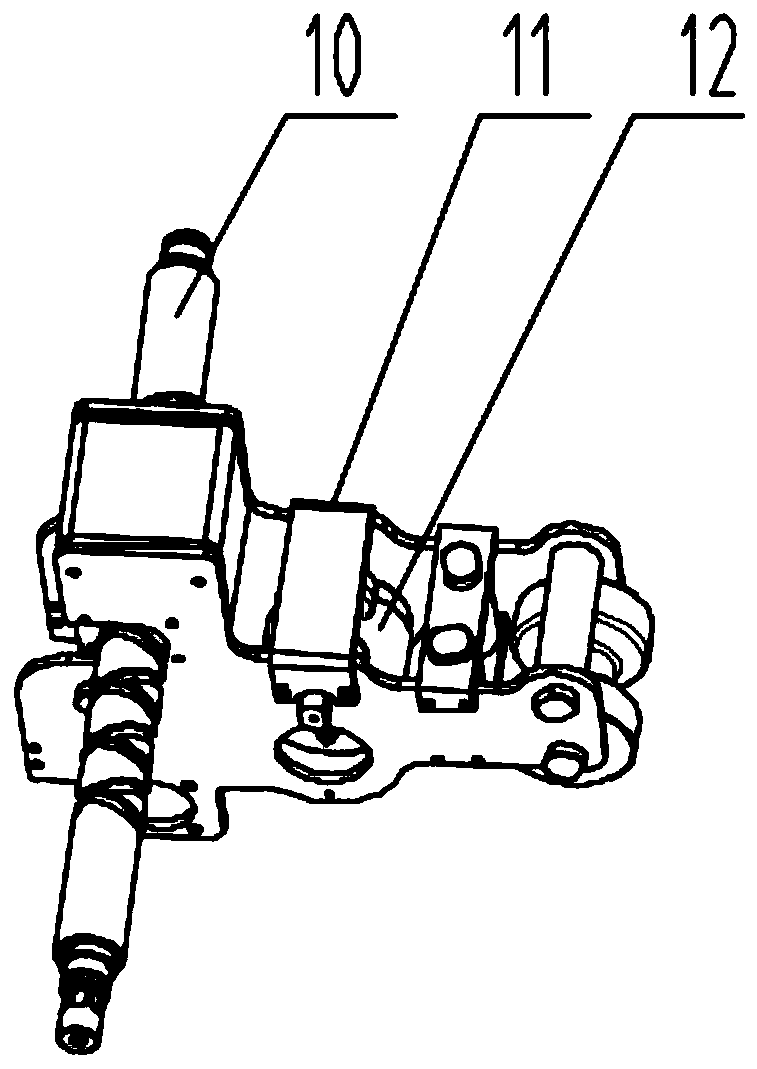

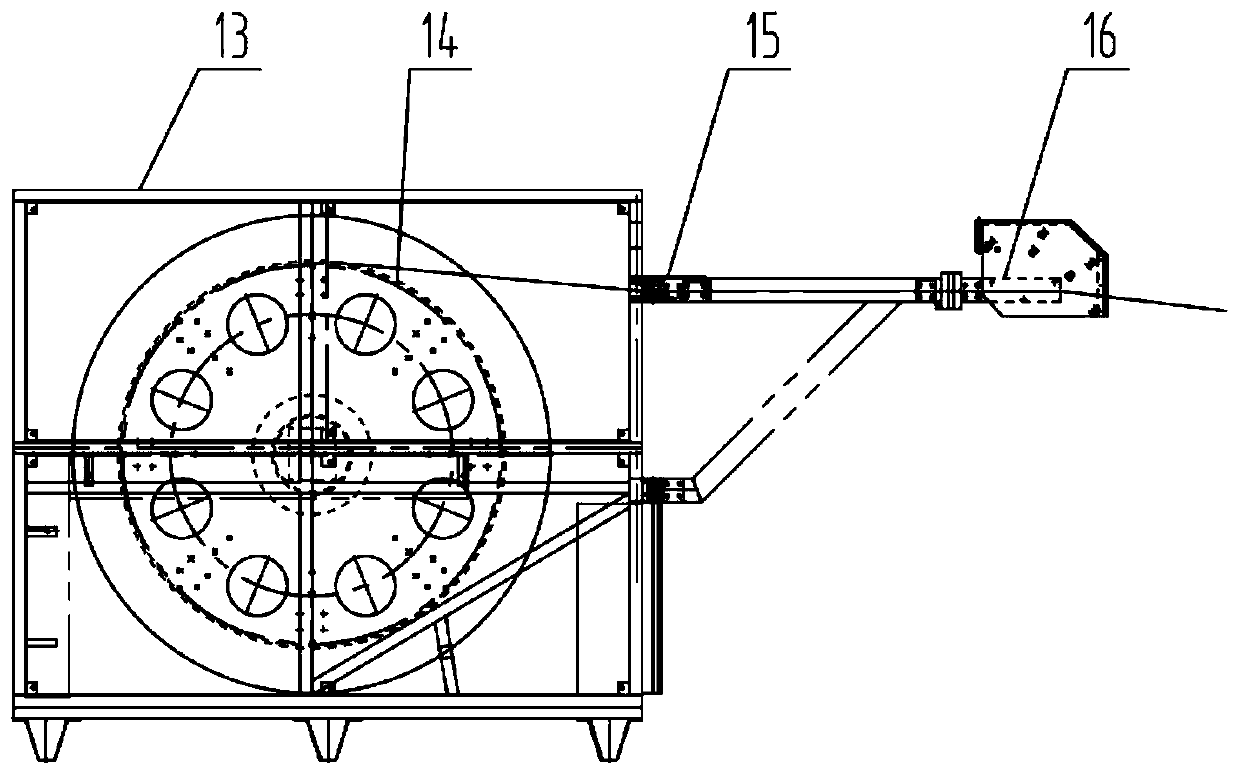

[0040] Such as Figure 1-5 As shown, the embodiment of the present invention provides a partial repair system for drainage pipes, including a downhole system and an uphole system;

[0041] The above-hole system includes a control system, a drive system, a blower fan and a generator set that provides power sources for the above-hole system and the down-hole system;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com