A self-heating hydrogen-oxygen catalytic burner and self-heating starting method

A catalytic burner, self-heating technology, applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve the problems of potential safety hazards, no measures to prevent tempering, etc., achieve stable heat supply, and improve the form of catalysts , Solve the effect of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

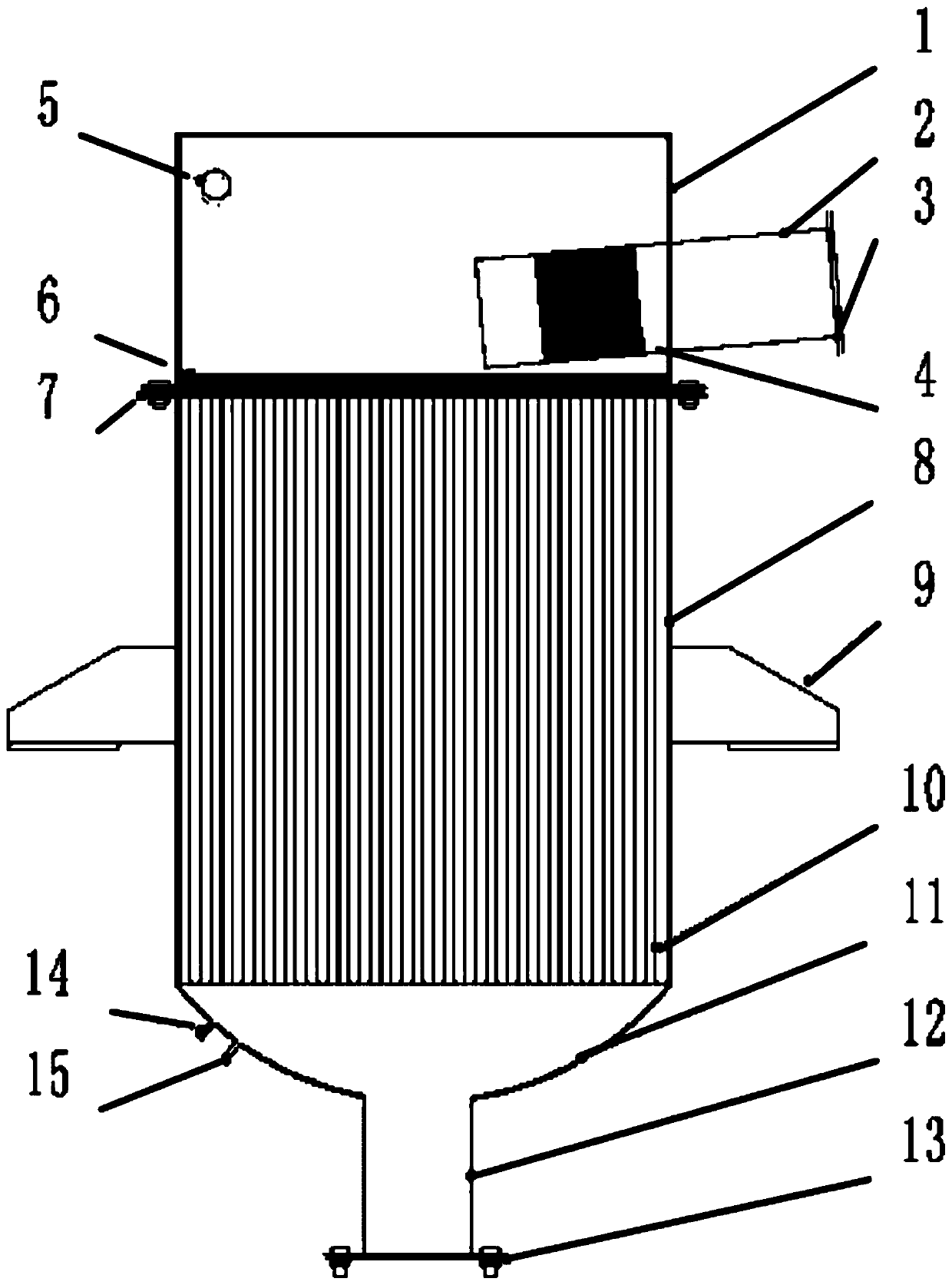

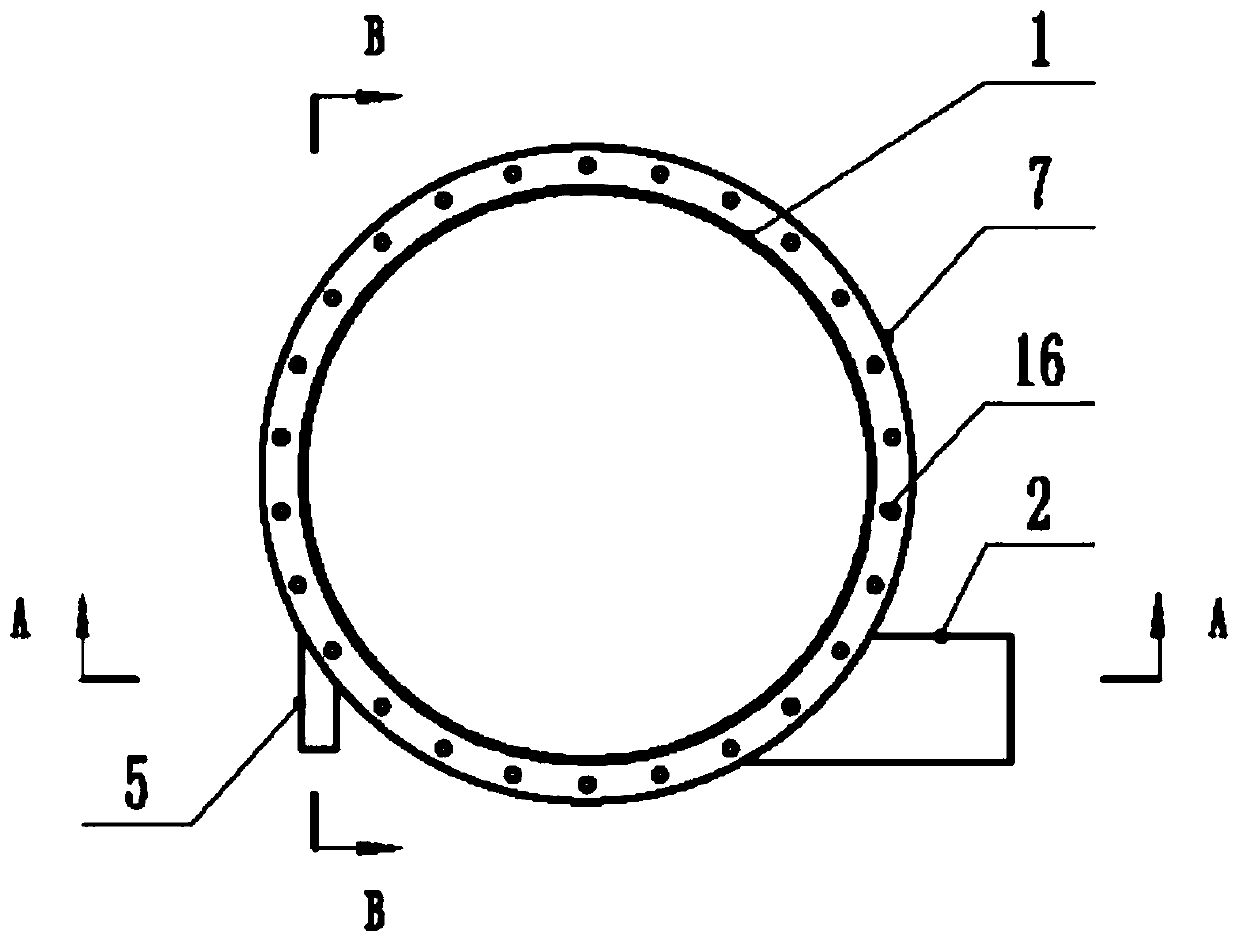

[0030] refer to Figure 1 to Figure 4 As shown, the present invention discloses a self-heating hydrogen-oxygen catalytic combustor, including a gas mixing chamber 1 with a cavity, and an air pipeline 2 and a hydrogen pipeline 5 vertically arranged in the gas mixing chamber 1, the hydrogen gas The pipeline 5 is arranged above the air pipeline 2, and the air pipeline 2 and the hydrogen pipeline 5 both extend outward along the tangential surface of the gas mixing chamber 1, and at the same time form an angle of 10-20° with the horizontal line, so that the air and the hydrogen are tangentially The gas flows into the gas mixing chamber 1, and the flow rate of hydrogen and air is controlled at Mach 0.2 to ensure that the hydrogen pressure is greater than the air pressure, so as to prevent oxygen (or air) from entering the hydrogen pipeline 5 and prevent hydrogen and oxygen from burning in the hydrogen pipeline 5 , the air pipeline 2 and the hydrogen pipeline 5 are respectively arran...

Embodiment 2

[0034] The gas mixing chamber 1 has a diameter of 60 mm and a height of 40 mm. The hydrogen gas pipeline 5 and the air pipeline 2 are vertically arranged, and the flow rate of the gas mixture is controlled to Mach 0.1. Nickel foam is processed into an air duct flame arrester 4 with a thickness of 5mm, a hole number of 40PPI, and a porosity of 40%. The gas distributor 6 is also processed from nickel foam, with a thickness of 7mm, a number of holes of 50PPI, and a porosity of 60%. When the catalytic plate 10 is produced, the thickness of the aluminum foil substrate is 4 mm, and the 20 μm hydrophobic γ-Al 2 o 3 For the transition layer, a 0.5 μm platinum active layer is deposited, platinum accounts for 0.8% of the mass of the transition layer, and the average diameter of platinum particles is 5 nm. The catalytic plate 10 is folded into a catalytic combustion chamber 8 with a pore size of 200 μm. The size of the catalytic combustion chamber 8 is 60mm in diameter and 130mm in le...

Embodiment 3

[0037] The gas mixing chamber 1 has a diameter of 60 mm and a height of 40 mm. The hydrogen pipeline 5 and the air pipeline 2 are vertically arranged, and the velocity of the mixed gas is controlled at Mach 0.08. Nickel foam is processed into an air duct flame arrester 4 with a thickness of 5mm, a hole number of 40PPI, and a porosity of 40%. The gas distributor 6 is also processed from nickel foam, with a thickness of 6mm, a hole number of 40PPI, and a porosity of 50%. When the catalytic plate 10 is produced, the thickness of the aluminum foil substrate is 4 mm, and the hydrophobic γ-Al is coated with 30 μm 2 o 3 For the transition layer, a 1 μm platinum active layer is deposited, platinum accounts for 1% of the mass of the transition layer, and the average diameter of platinum particles is 5 nm. The catalytic plate 10 is folded into a catalytic combustion chamber 8 with a pore size of 100 μm. The size of the catalytic combustion chamber 8 is 60mm in diameter and 130mm in l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com