Circuit breaker fault detection device and multiple-data fusion fault detection method

A circuit breaker fault detection device technology, which is applied in the direction of circuit breaker testing, measuring devices, testing of machines/structural components, etc., can solve the problem that the working characteristics of circuit breakers are not exactly the same and affect them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

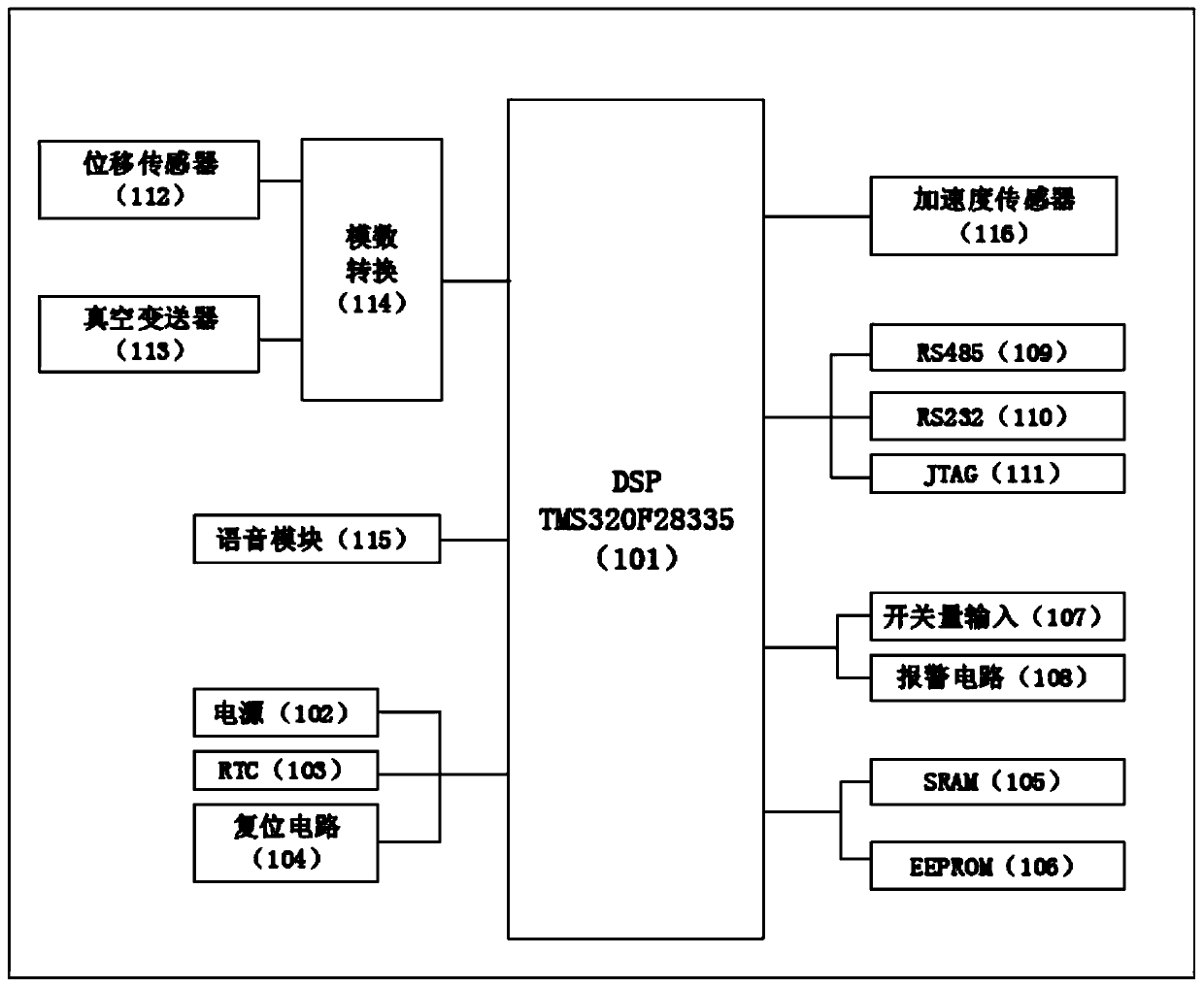

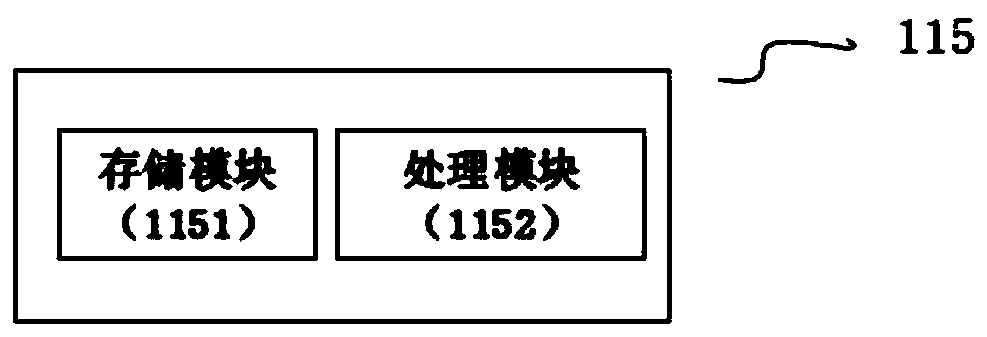

[0110] see figure 1 with 2 As shown, a circuit breaker fault detection device includes a central processing unit 101 and a power supply 102 connected thereto, an RTC timer 103, a reset circuit 104, a SRAM 105, an EEPROM 106, a digital input interface 107, an alarm circuit 108, an RS485 interface 109, RS232 interface 110 , JTAG111 , displacement sensor 112 , vacuum transmitter 113 , analog-to-digital converter 114 , voice module 115 and acceleration sensor 116 .

[0111] The central processing unit 101 is a control chip for signal acquisition and processing, and adopts a TMS320F28335 chip produced by TI Company.

[0112]The output terminals of the displacement sensor 112 and the vacuum transmitter 113 are connected to the input terminal of the analog / digital converter 114, and the parallel interface of the analog / digital converter 114 is connected with the data bus of the processor 101, wherein the chip select terminal is connected with the XZCS0 of the processor 101 Connecte...

Embodiment 2

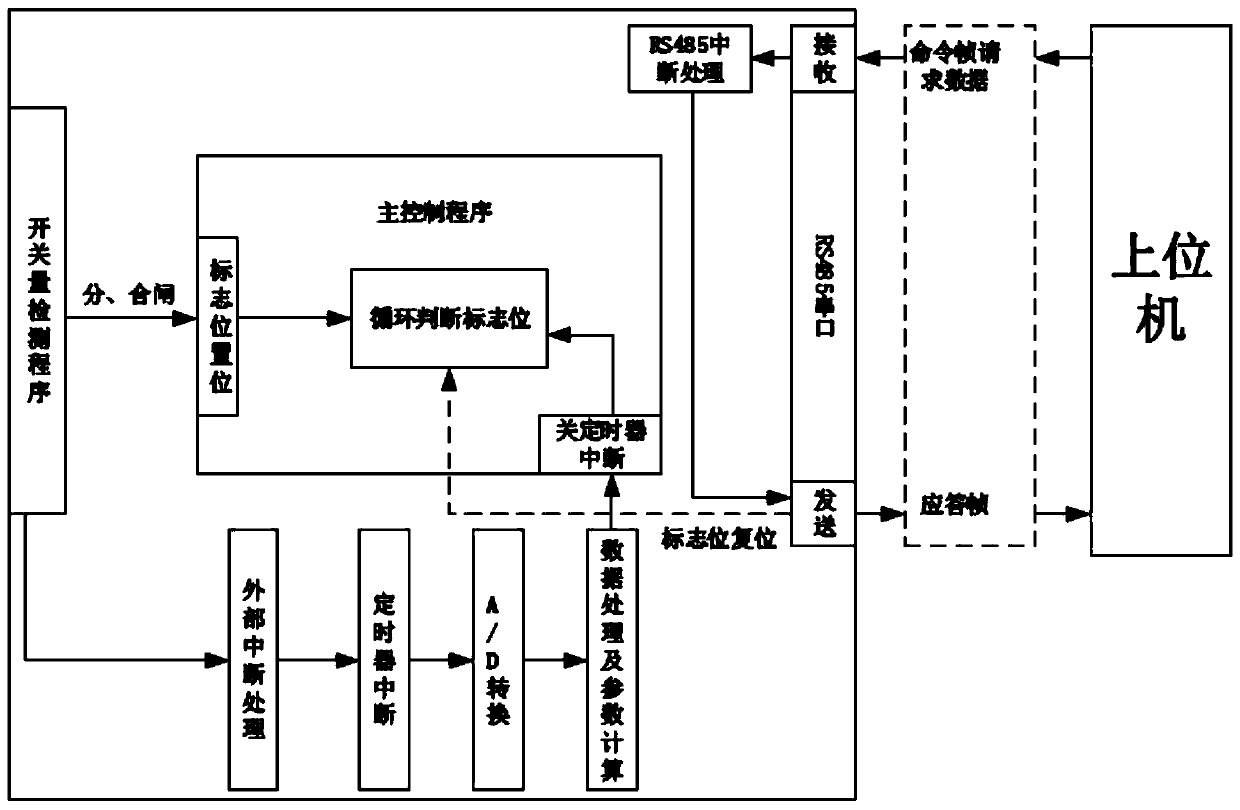

[0119] Please also refer to Figure 3-5 , a multiple data fusion fault detection method comprising the following steps:

[0120] Step A: Obtain the signal of opening and closing of the circuit breaker.

[0121] Step B: receiving the speech segment input, and extracting the speech feature parameter F1, which is 12-Vermel frequency cepstral coefficient.

[0122] Step C: Receive the output signal of the displacement sensor, and obtain the mechanical characteristic parameters F2 of the vacuum circuit breaker: closing (opening) time, contact stroke, opening distance, overtravel, closing (opening) average speed and just closing and opening speed.

[0123] Step D: Receive the output signal of the vacuum transmitter, and obtain the vacuum degree parameter F3 of the vacuum circuit breaker.

[0124] Step E: Receive the output signal of the acceleration sensor, and obtain the characteristic parameter F4 of the 5-dimensional vibration signal of the circuit breaker.

[0125] Step F: Obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com