A loading device capable of sequentially applying impact loads and steady-state loads

A technology of impact load and loading device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of low frequency response, high cost, and increased flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the implementation of the technical solution of the present invention in detail in conjunction with the accompanying drawings.

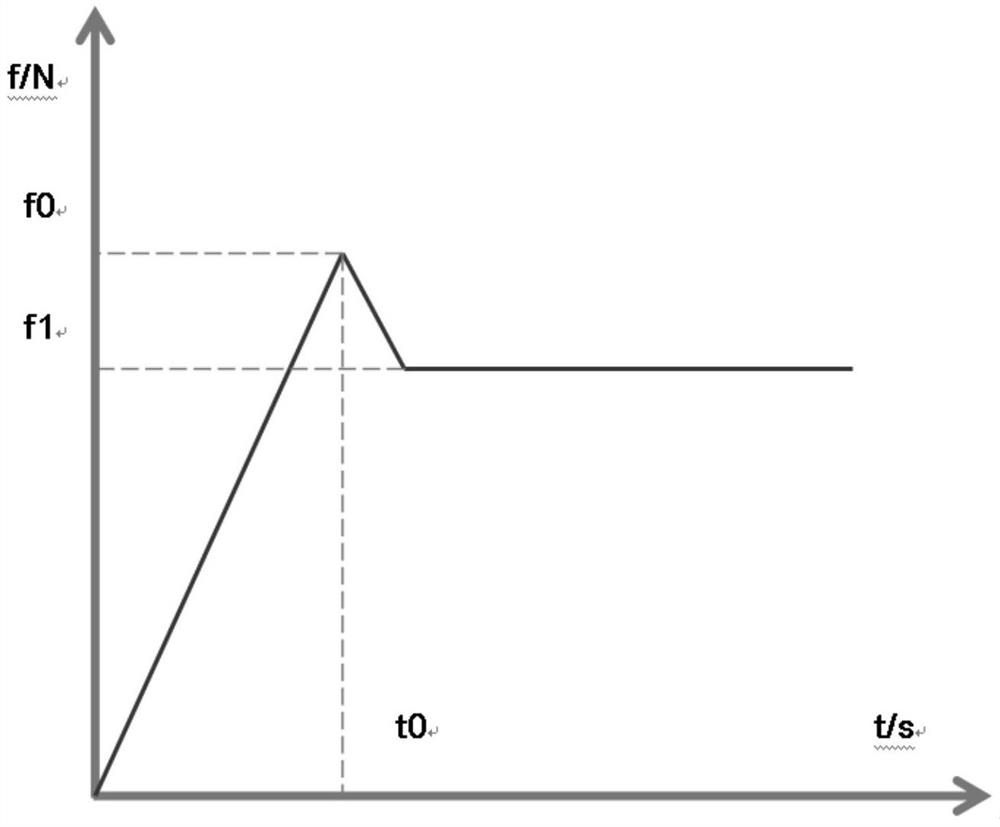

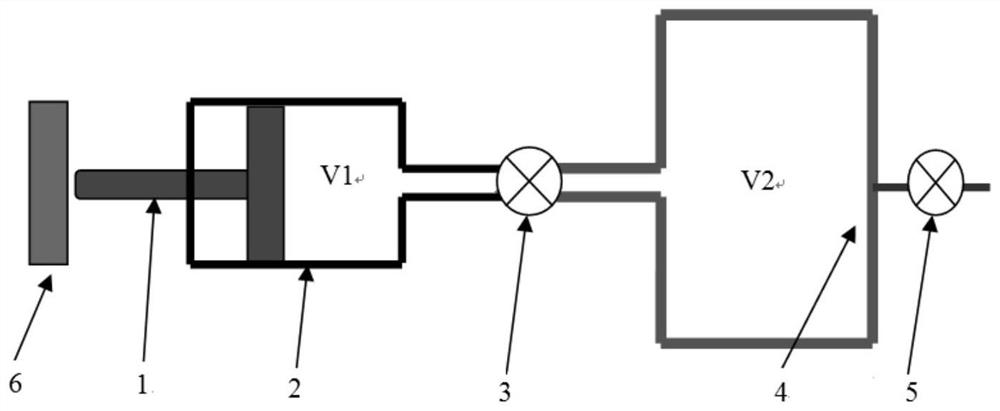

[0023] The loading device includes a loading piston 1, a cylinder 2, a pneumatic valve 3, an energy storage tank 4, and an inflatable solenoid valve 5; the loading piston 1 is located in the cylinder 2, cooperates with the cylinder 2 without clearance, and can slide axially along the cylinder; the loading piston The loading end of 1 and the loading object 6 can be connected according to the test requirements. When the test requires a collision impact with speed, a certain distance is reserved between the two, otherwise the two are fixed; the cylinder 2 and the energy storage tank 4 pass through Pneumatic valve 3 is connected, and can control the flow rate and flow rate of the compressed gas in 4 to the outer cylinder 2 according to the waveform requirements, and generate a predetermined waveform; the energy storage gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com