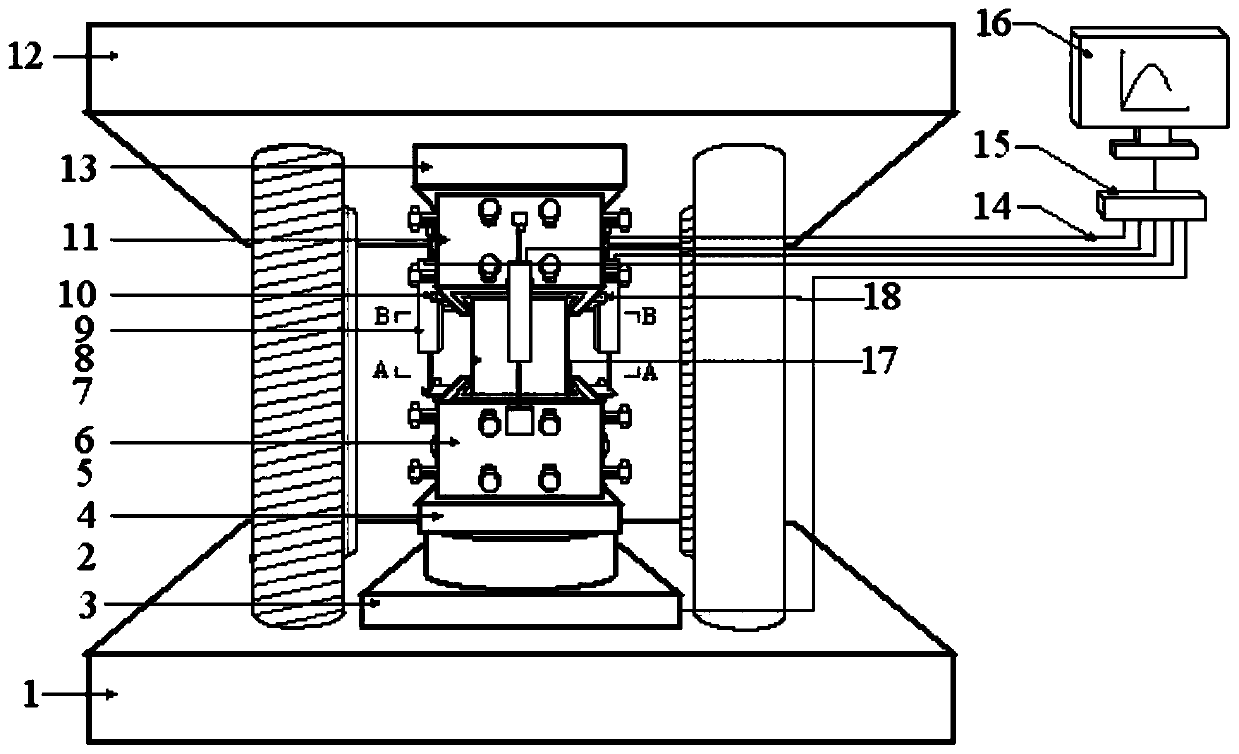

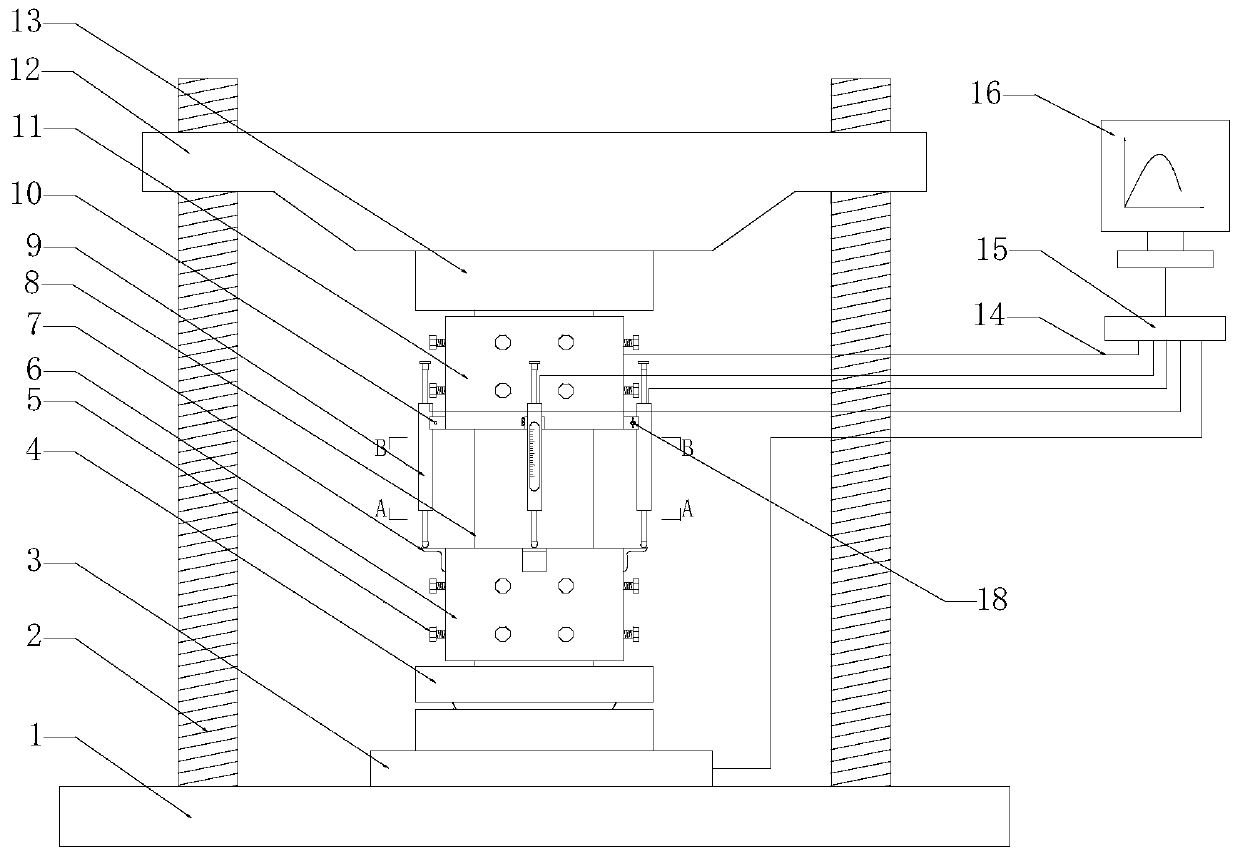

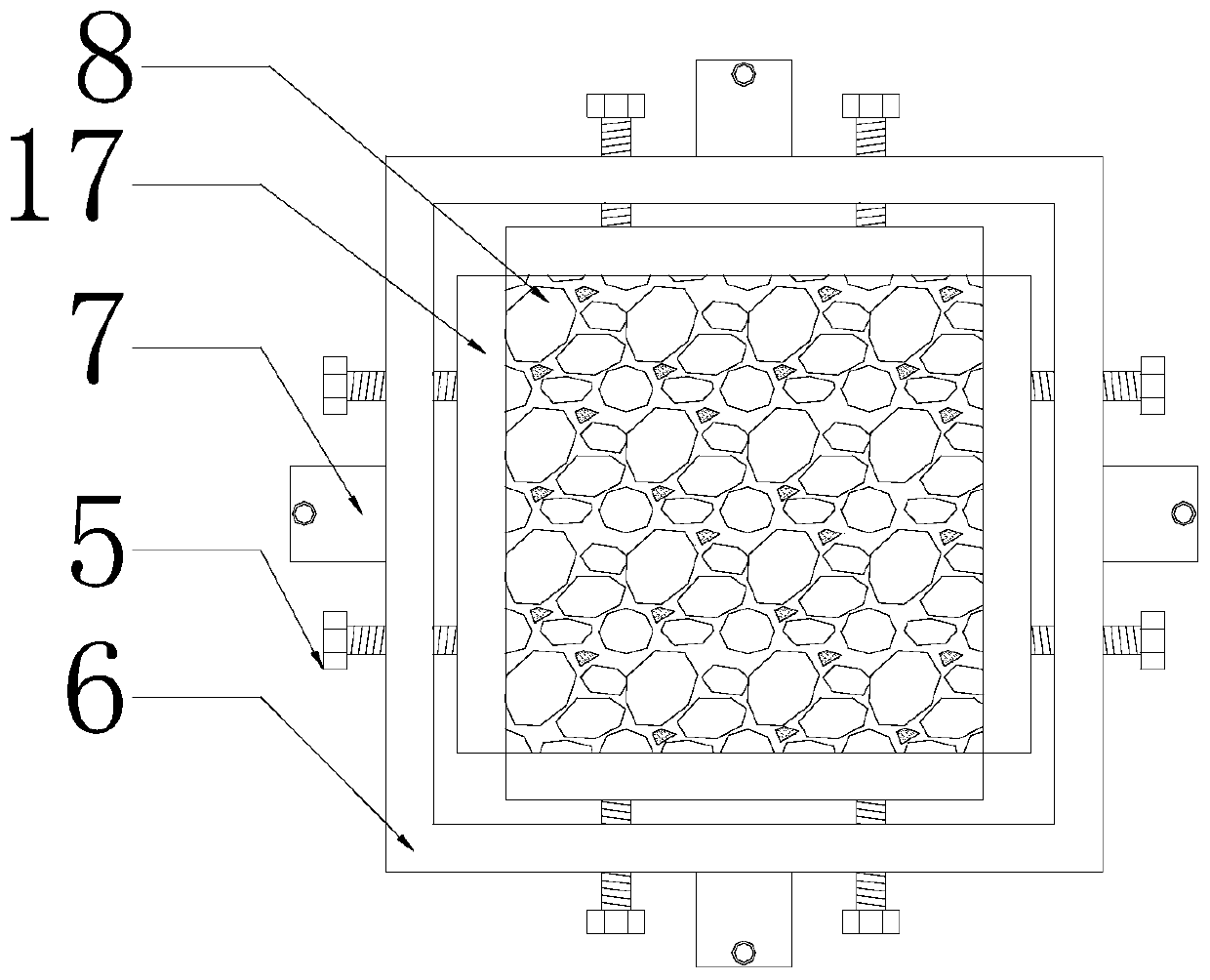

Concrete stress-strain full-curve test apparatus and working method

A testing device, full curve technology, applied in the direction of measuring device, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem of not being able to obtain high-performance concrete deformation, high-performance concrete failure strength, and not being able to obtain ideal experiments Effect and other issues, to achieve the effect of simple structure, firm device, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The raw materials of this example: high-strength crushed stone ceramsite concrete is used for pouring, of which 900 grade crushed shale ceramsite is used for light aggregate, Conch brand PO42.5 cement is used for cement, and Weihe medium sand is used for fine aggregate with auxiliary gelling The materials are silicon fume and grade I fly ash, the admixture is BKS-199 superplasticizer, and the participating fibers are steel fiber (SF) and carbon fiber (CF).

[0061] The test specimens use concrete strength grade, fiber type, and fiber content as varying parameters. There are two strength grades LC50 and LC60. The fiber volume ratio of carbon fiber high-strength lightweight aggregate concrete is 0.6% and 0.9%, and steel fiber high-strength lightweight aggregate concrete The fiber volume ratio of concrete is 0.6% and 0.9%. The mix ratio of high-strength lightweight aggregate concrete and fiber concrete is shown in Table 1.

[0062] Table 1 Mix ratio design of high-strength lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com