Hardware switch capable of prolonging working cycle

A technology of working cycle and hardware, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of connecting offset of metal switch cover, increasing working cycle, shortening working cycle, etc., so as to ensure normal operation and expand working cycle , to ensure the effect of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with examples.

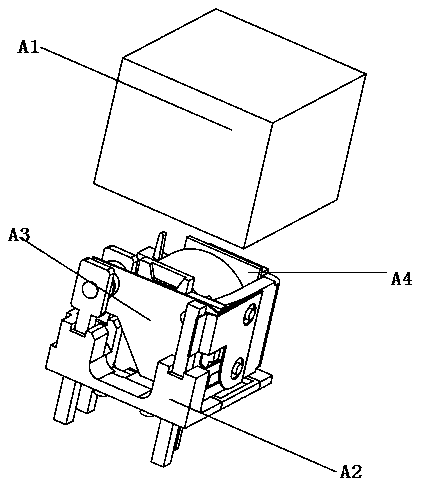

[0017] like Figure 1-Figure 3 As shown, the metal switch with increased working cycle of this embodiment includes an outer cover A1, a support platform A2, a nickel plate A3, and a nickel strip. The support platform is equipped with contacts and a spiral glass bronze wire A4, and the outer cover A1 is supported together. Unit A2 can be decomposed and connected;

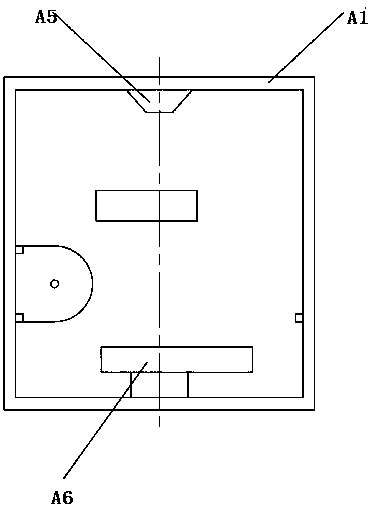

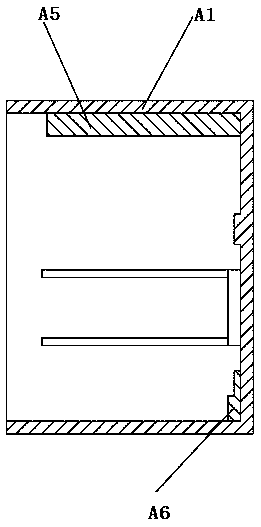

[0018] Keep a distance between the head of the positioning protrusion A5 and the spiral glass bronze wire A4. The positioning protrusion A5 has the function of avoiding excessive deformation in the middle of the spiral glass bronze wire, so as to ensure the normal operation of the hardware switch and expand the working cycle; The bottom of the cover A1 is equipped with a protrusion. After the cover A1 is equipped with the support platform A2, the protrusion A6 is in contact with the head of the nickel plate A3, so as to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com