Composite gear motor generator

A technology for gear motors and generators, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of high cost and large volume of hydraulic motor-generator units, and achieve light weight, convenient installation and maintenance, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

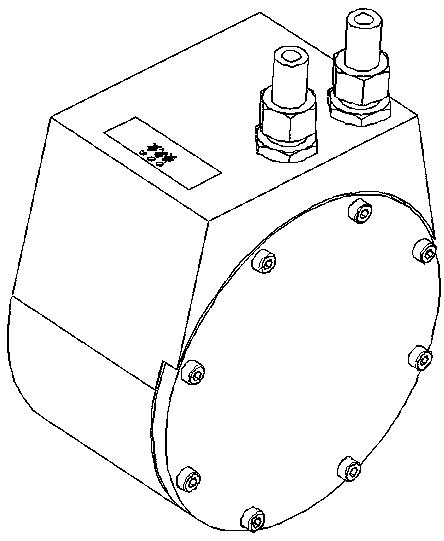

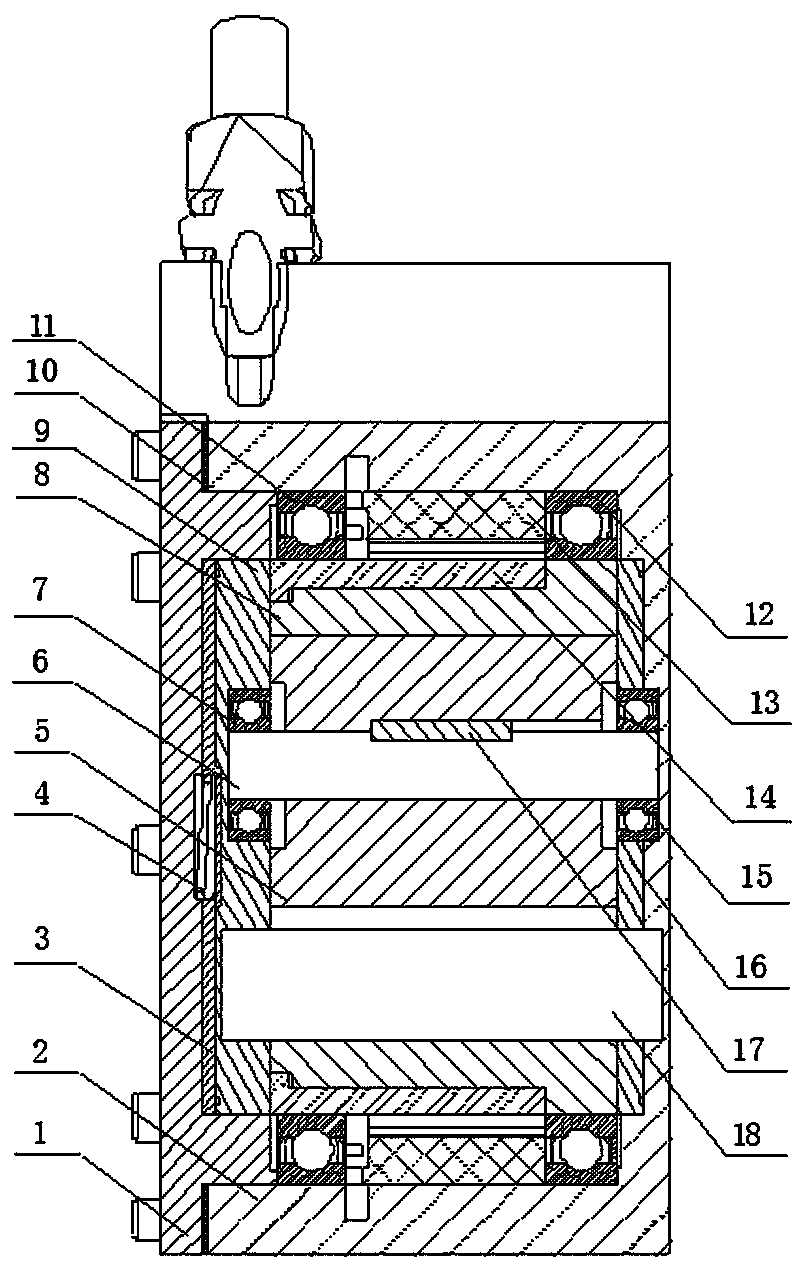

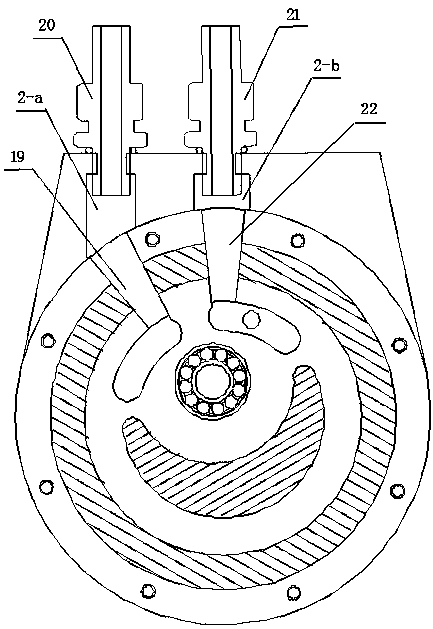

[0007] Such as figure 1 , figure 2 As shown, the present invention is a compound gear motor generator, which is composed of a motor assembly and a power generation assembly. The pinion gear 5, the internal gear 8, the first motor side plate 9, the second motor side plate 16 and the crescent The body 18 constitutes a closed volume, and the oil suction chamber and the oil pressure chamber are separated by the crescent body 18. The pinion 5 is connected with the pinion shaft 6 through the round key 17, and the crescent body 18 is installed between the pinion 5 and the internal gear 8. A spring 4 is installed between the motor cover 1 and the baffle 3, and the baffle 3 is in direct contact with the first motor side plate 9, so that the first motor side plate 9 and the second motor side plate 16 can align the internal gear 8 and the pinion. 5, the pinion shaft 6 is supported on the first motor side plate 9, the second motor side plate 16 and the housing 2 through the first small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com