Pre-cutting tip removing device of sugarcane harvester

A technology for harvesters and sugarcane, which is applied to harvesters, agricultural machinery and implements, etc., can solve the problems of multiple procedures for cutting tip cutting and complex mechanisms for cutting sugarcane tips, so as to reduce the link of tip removal, high reliability, and improve The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

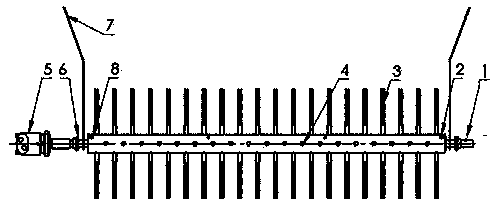

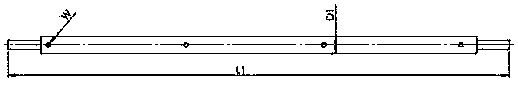

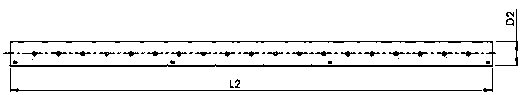

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Such as Figure 1~7 Shown: the tip removal device of the sugarcane harvester before cutting, including: rotating shaft 1, soft glue stick fixing sleeve 2, soft glue stick 3, soft glue stick fixing hole 4, motor 5, bearing seat 6, sugarcane holding board 7 ; First, the soft glue stick fixing sleeve 2 is axially set on the rotating shaft 1, the motor 5 is installed on one end of the rotating shaft 1, and the two bearing seats 6 are respectively installed on both ends of the rotating shaft 1, and the soft glue stick 3 passes through the soft glue stick in turn. The fixed hole 4 is axially installed on the soft glue stick fixed sleeve 2 in a criss-cross pattern, and the two sugarcane plates 7 are fixedly installed on the inner side of the bearing seat 6 at the two ends of the rotating shaft 1 respectively.

[0025] According to the requirements of the sugarc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com