Full-automatic cooker

A cooking machine, fully automatic technology, applied to cooking utensil lids, heating devices, cooking utensils, etc., can solve the problems of inconvenient use and inconvenient cleaning, and achieve the effect of convenient sealing film, easy cleaning and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

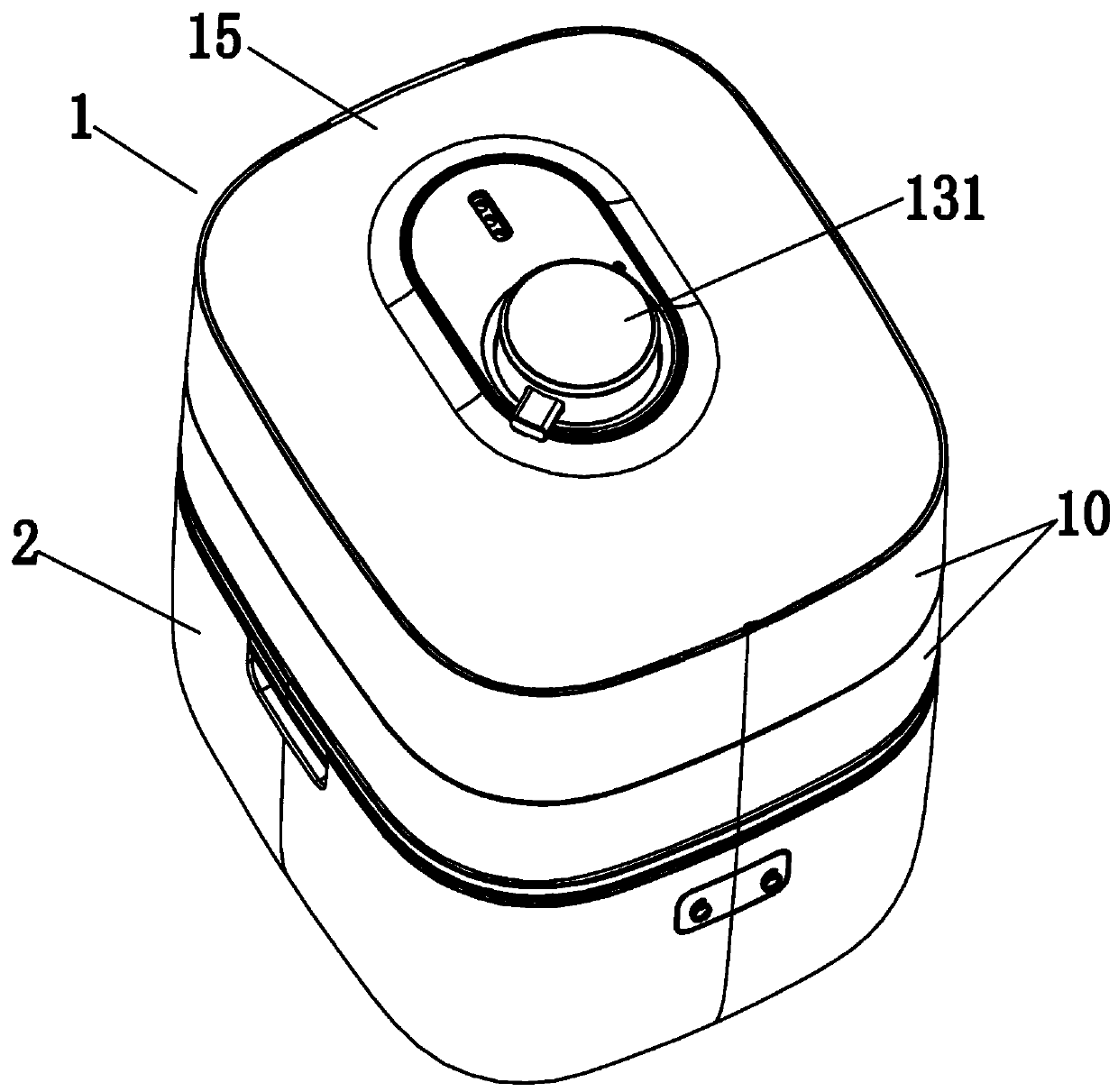

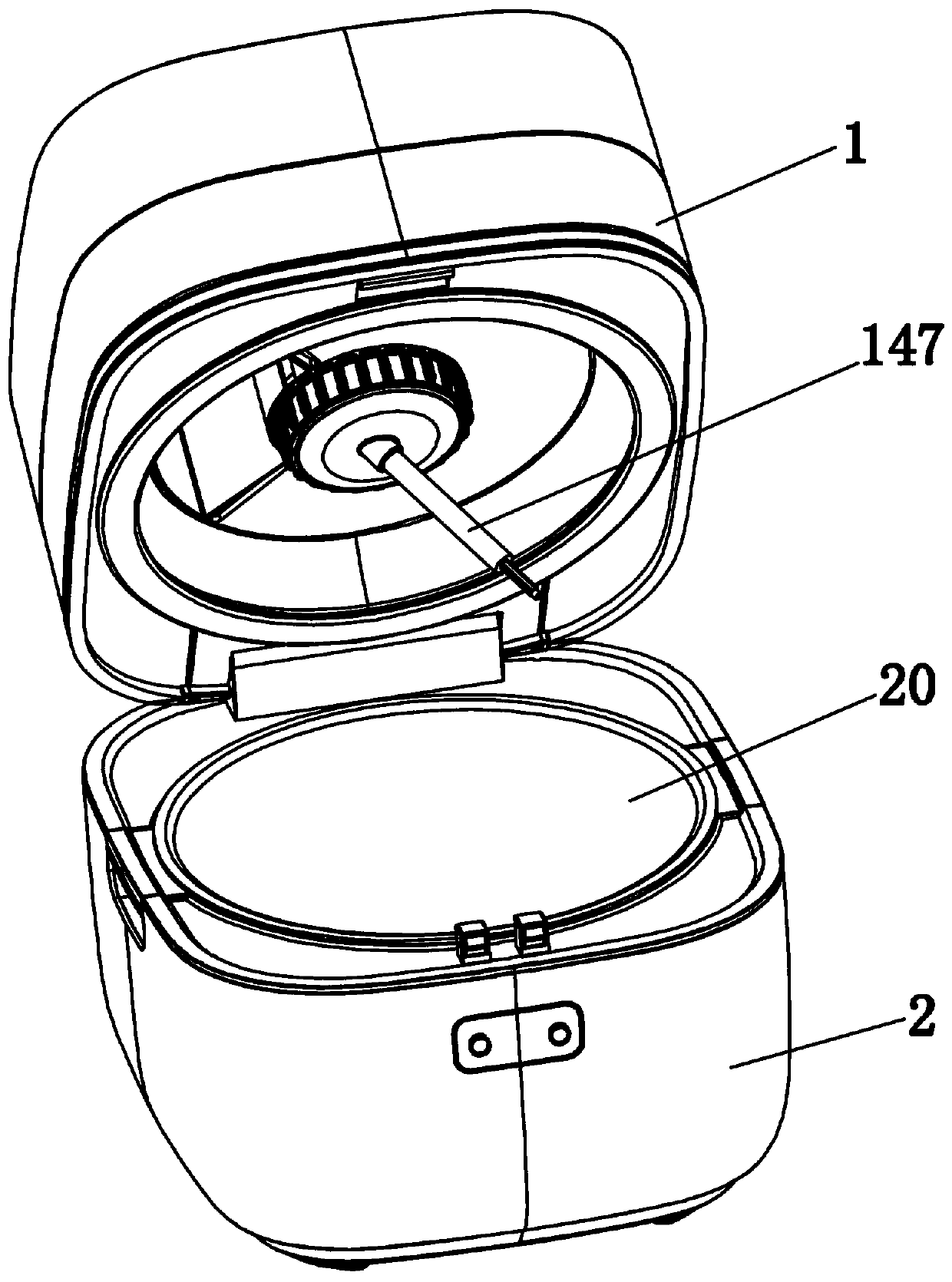

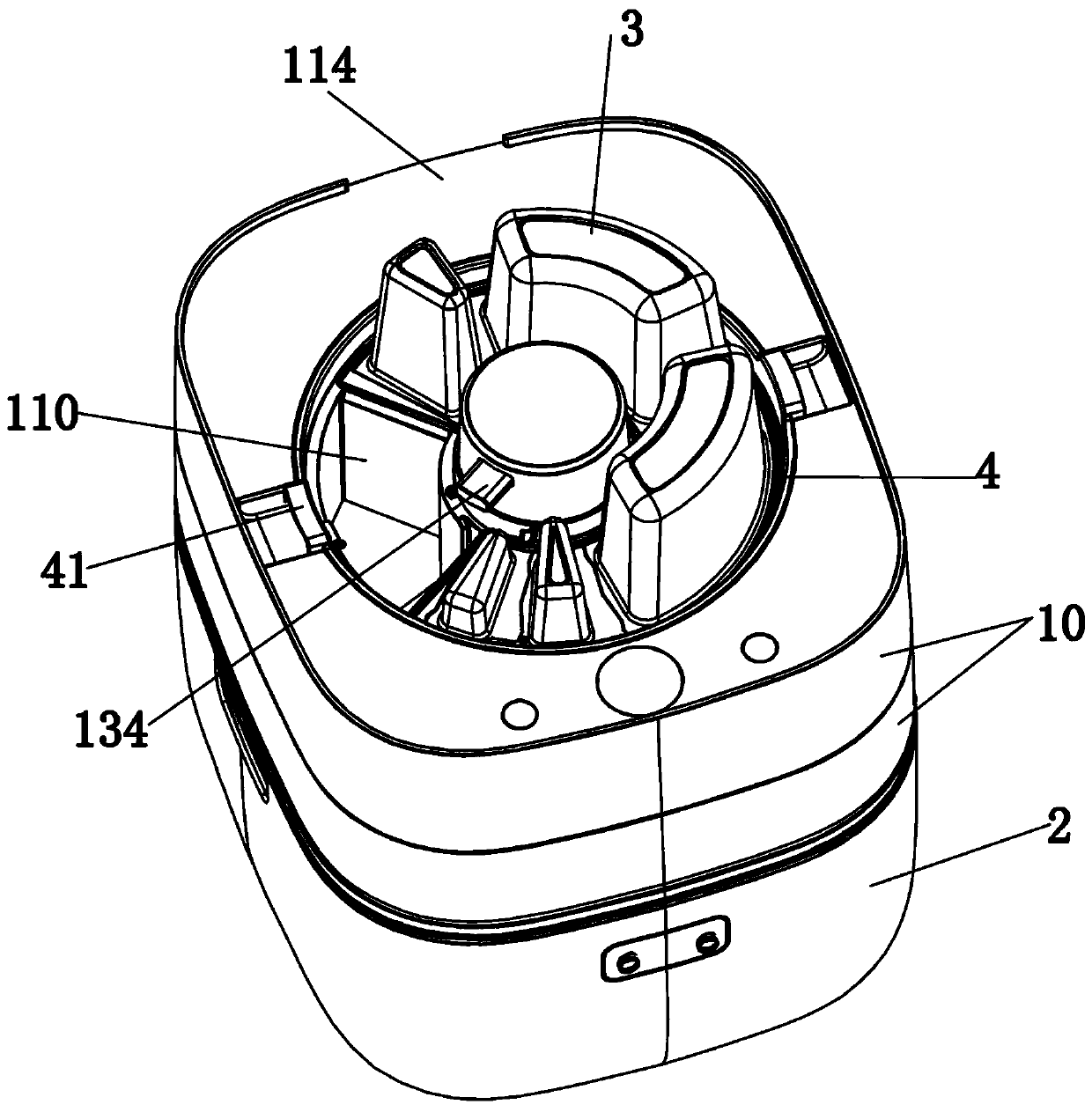

[0049] Embodiment one, such as Figure 1 to Figure 13 Shown, a fully automatic cooking machine, including a pot cover 1, a heating base 2, a circuit board 5, an identification code scanning device 6 and a cloud server, the rear side of the pot cover 1 is rotated and set on the top of the heating base 2, so The front side of the pot cover 1 is snap-connected with the heating base 2, and the heating base 2 is provided with a heating device and a cooking pot body 20, and the pot cover 1 and the cooking pot body 20 are closed up and down to form a cooking cavity The pot cover 1 includes a pot cover body 10, a food box tearing film and a rotating drive mechanism 12, a food box vibration mechanism 13 and a cooking mechanism 14, and the food box vibration mechanism 13 is located on the top of the pot cover body 10. The top of the pot cover body 10 is provided with a food box rotary feeding chute 111, and the food box rotary feeding chute 111 is provided with a blanking port 110, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com