Active carbon conveying and injecting system and process for purifying smoke using system

An injection system and activated carbon technology, which are applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low purification efficiency, inability to effectively control the amount of activated carbon injection, and low safety, etc., to improve purification efficiency and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

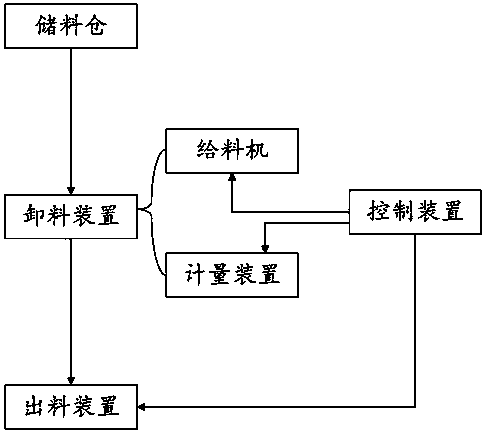

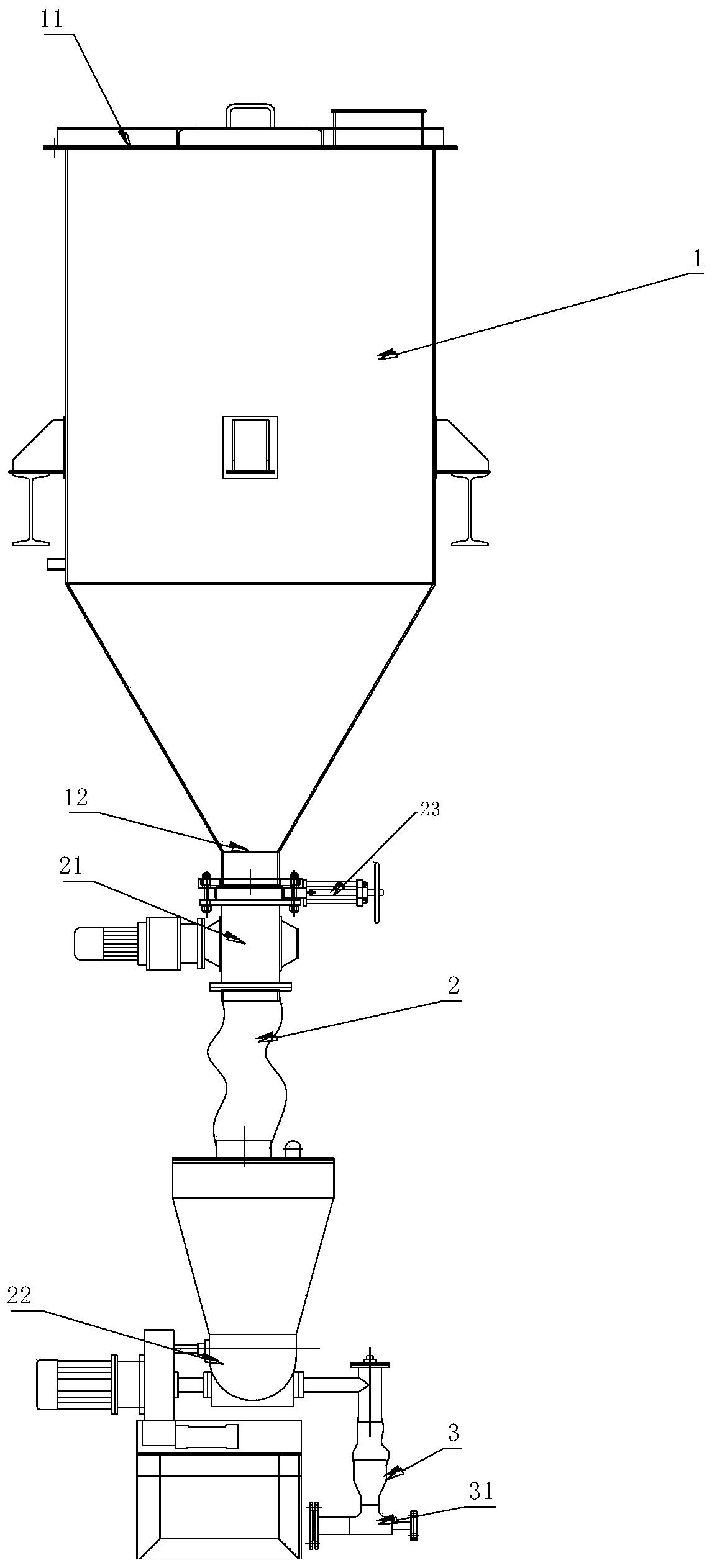

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following specific embodiments are combined with reference to the attached Figure 1-2 , The present invention is further explained in detail.

[0027] The specific technical scheme of the activated carbon delivery and injection system provided by the present invention is as follows:

[0028] The activated carbon delivery and injection system includes a storage bin 1, a discharge device 2, a discharge device 3 and a control device. The storage bin 1 forms a feed port 11 and a discharge port 12. The discharge device 2 includes a feeder 21 and a metering device 22. The feeder 21 is connected to the discharge port 12, and the metering device 22 is connected to the feeder 21, The discharging device 3 includes an activated carbon ejector 31, which is connected with a discharge pipe which forms a discharge port and is connected to a flue, and the discharge pipe is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com