Sleeve needle suitable for magnetic bead washing system

A magnetic bead cleaning and trocar needle technology, applied in the field of trocar needles, can solve the problems of easy adhesion on the outer wall of the liquid suction needle, difficulty in cleaning the outer wall of the liquid suction needle, affecting the accuracy of detection results, etc., and achieves a simple structure. , The cleaning effect is good, the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

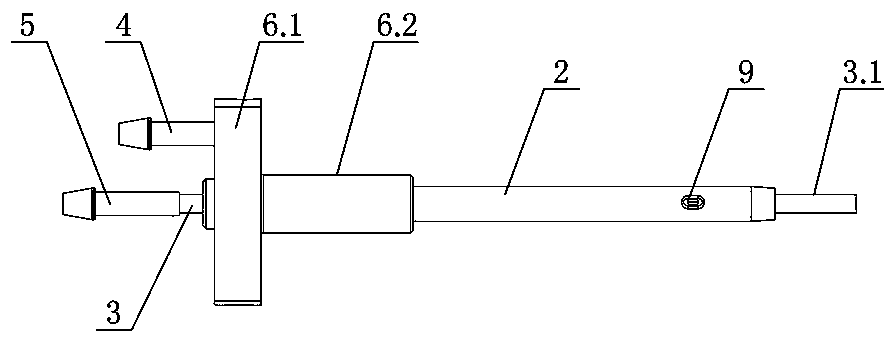

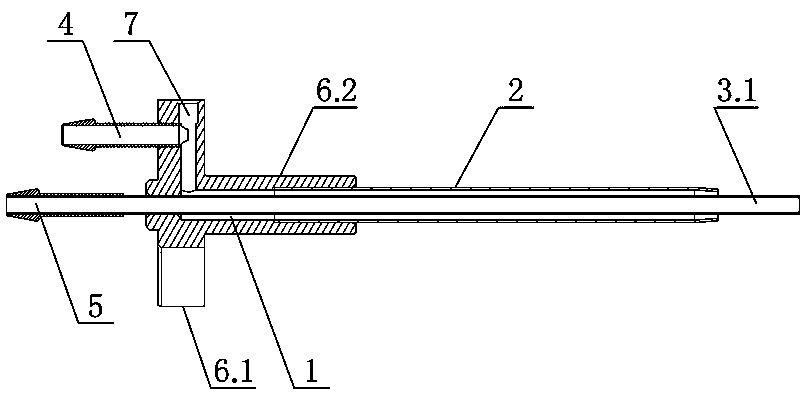

[0034] Such as figure 1 , 2 As shown, the sleeve needle suitable for the magnetic bead cleaning system of the present invention includes a connecting seat, and the connecting seat is a T-shaped structure composed of a fixing seat 6.1 and a cross bar 6.2, and a transverse An extended installation groove 1, the outer cleaning needle 2 extending outward is inserted in the installation groove 1, the inner liquid suction needle 3 is arranged in the outer cleaning needle 2, and the outer end of the inner liquid suction needle 3 faces The outer end of the outer cleaning needle 2 extends outward to form an insertion section 3.1. In order to ensure the stability of the connection between the inner liquid suction needle 3 and the outer cleaning needle 2, it is set on the outer cleaning needle 2 or the inner liquid suction needle 3 close to the insertion section 3.1. with fixed components,

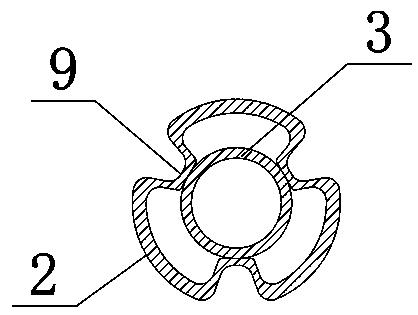

[0035] Such as Figure 3.1 As shown, the fixing assembly is a fixing groove 9 formed by the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com