Welding feeding mechanism with iron core positioning rod assembling and disassembling function

A positioning rod and iron core technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the unfavorable design and introduction of the automatic installation mechanism of the positioning rod of the iron core, the inability to further improve the production efficiency of the iron core, and the guide rail Reduced service life and working reliability, etc., to achieve the effect of favorable design and introduction, simple structure, simple and fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

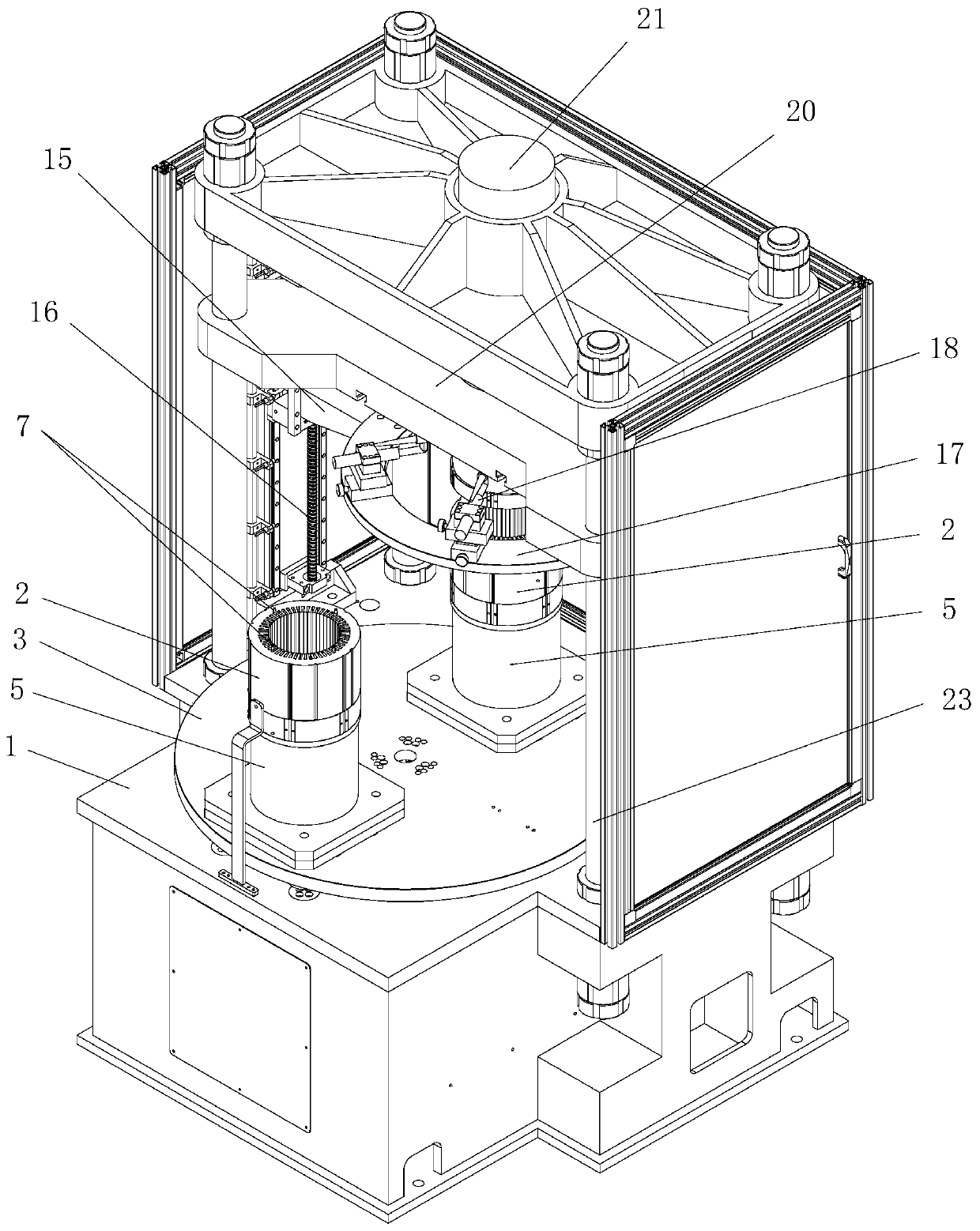

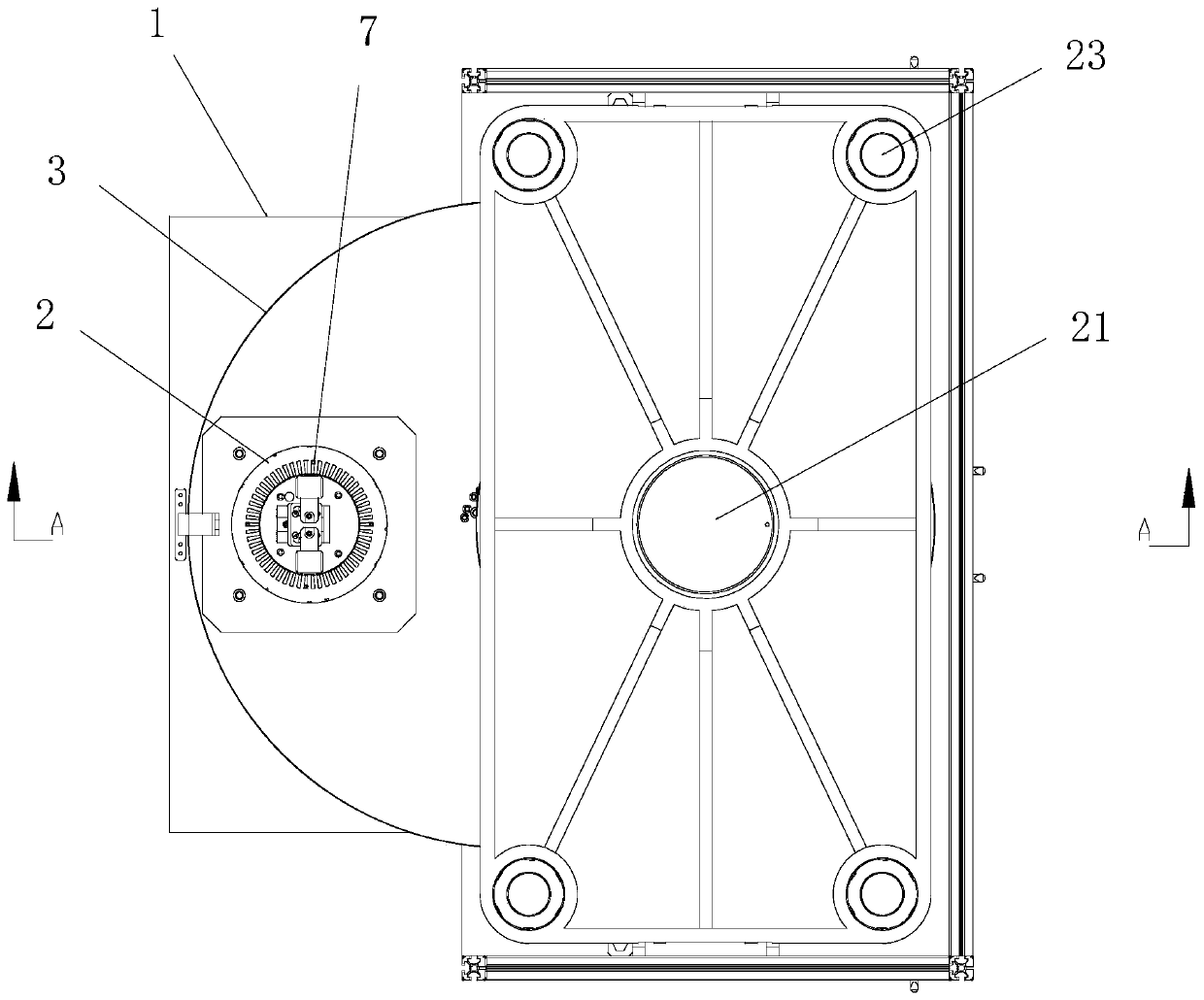

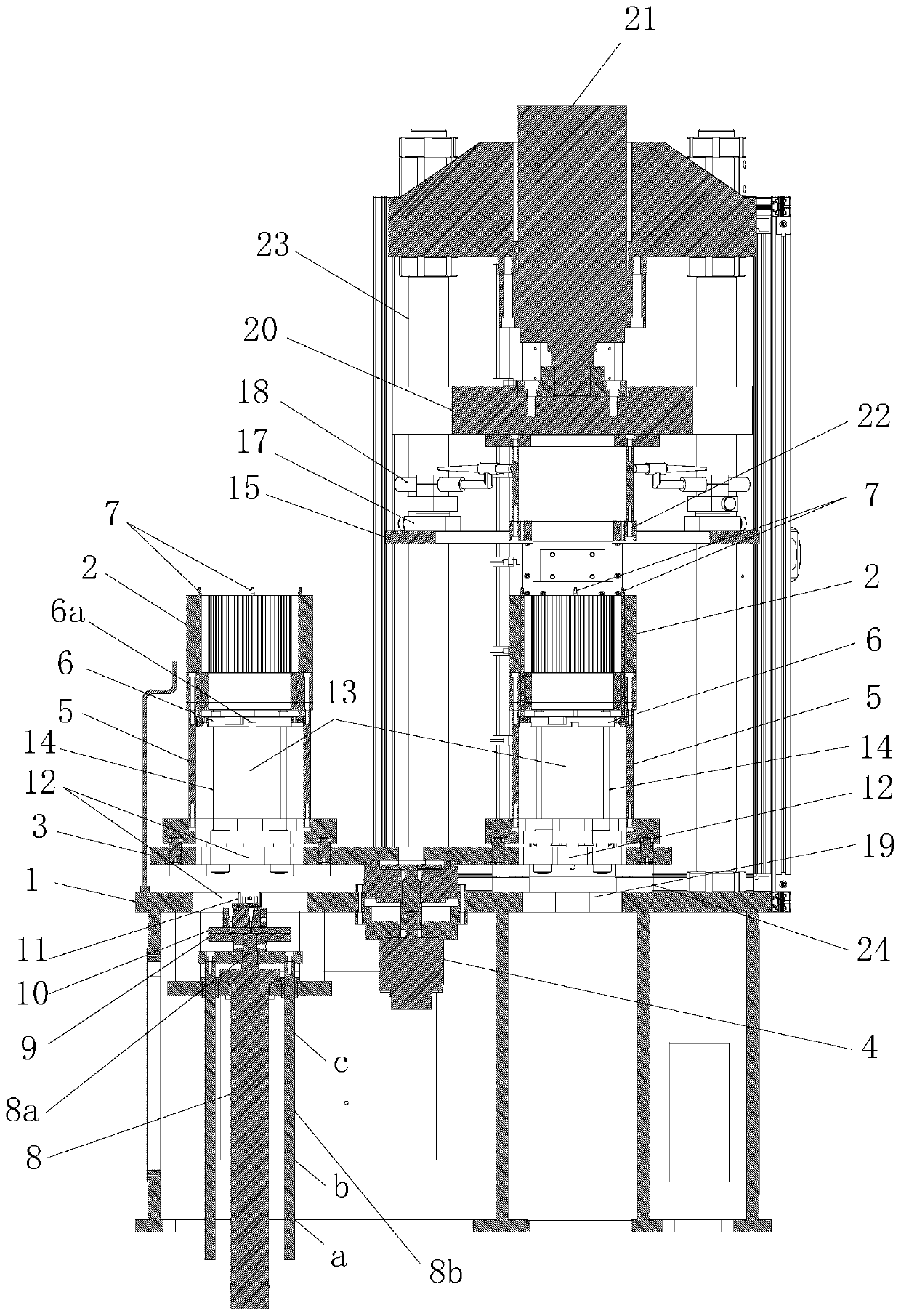

[0041] Embodiment: combine below Figure 1~Figure 3 The specific implementation of the welding feeding mechanism with the function of loading and unloading the iron core positioning rod provided by the present invention is described as follows. Such as Figure 1~Figure 3 It is the welding machine complete machine of the present invention that has been installed. Like the conventional technology, it has a workbench 1 with a welding station, a welding mechanism and a sheet arrangement mechanism arranged on the workbench 1 corresponding to the welding station, and a welding mechanism located on the workbench. 1 is used to transport the feeding mechanism of the iron core 2 to the welding station. The core improvement of the present invention for the feeding mechanism is to set an indexing rotary feeding mechanism on the workbench 1, and correspondingly design the automatic positioning of the iron core positioning rod. Loading and unloading mechanism.

[0042] combine Figure 1~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com