Holding equipment for holding circuit boards, etc.

A kind of equipment and retention technology, which is applied in the direction of circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of covering part or sticking part falling off, costly sticking or covering opening, wrong process of substrate, etc., so as to reduce time consumption and improve Printing accuracy, the effect of reducing the printing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

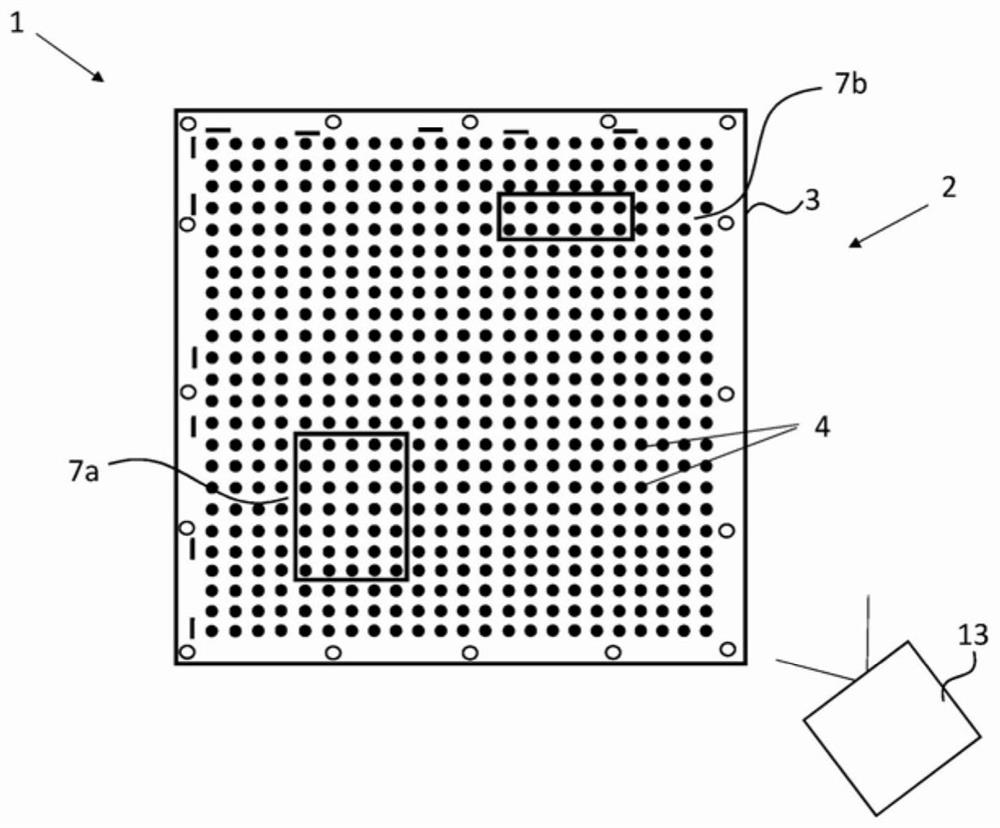

[0040] figure 1 A view from above shows a part of a holding device according to an embodiment of the invention.

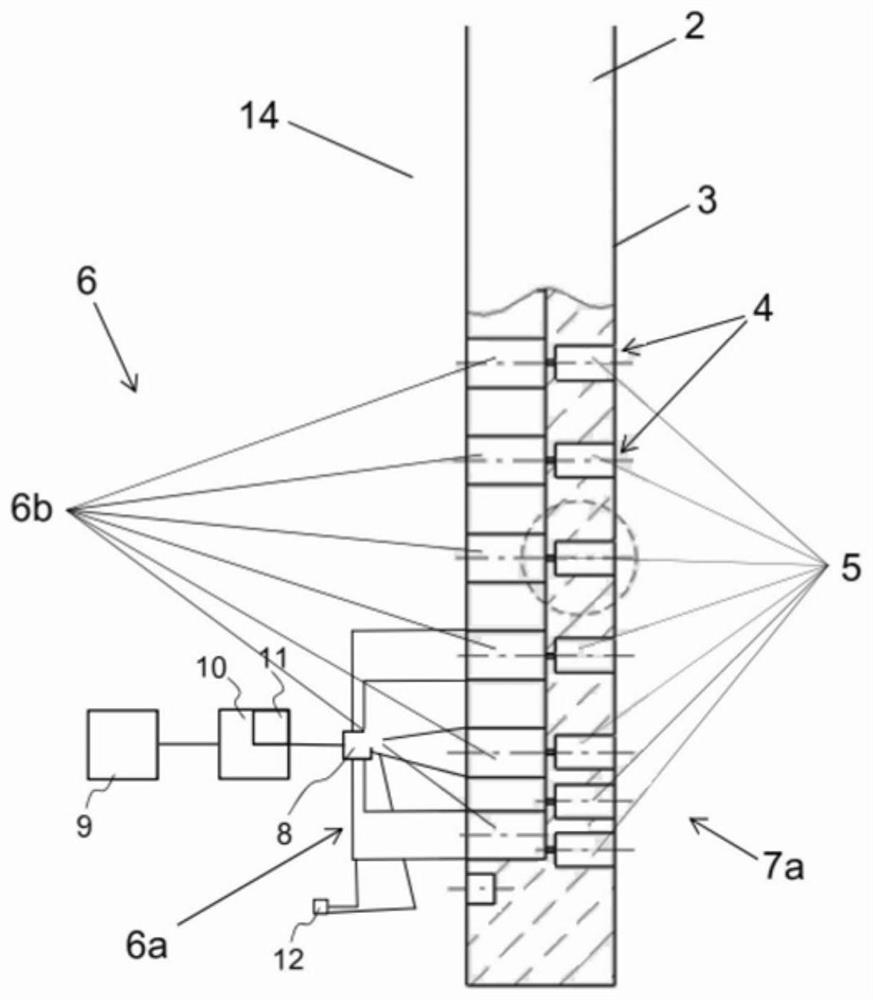

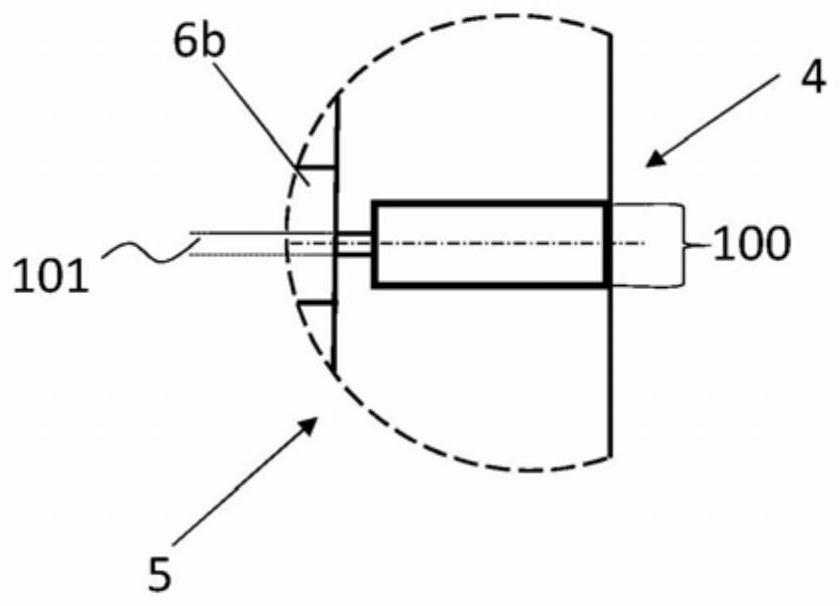

[0041] exist figure 1 The holding device 1 is shown in plan view. The holding device 1 has a rectangular vacuum suction plate 2 with a suction surface 3 for the substrate. The vacuum suction plate can here also be circular, oval or also have any other shape. Adsorption ports 4 are arranged in the adsorption surface 3 , and the adsorption ports are arranged at certain intervals or evenly distributed on the adsorption surface 3 . A negative pressure is generated on the upper side of the vacuum suction plate 2 , by means of which vacuum the substrates arranged on the vacuum suction plate 2 are held in place. In addition, in figure 1 Suction zones 7a, 7b are exemplarily shown in , which can be controlled separately and which serve to hold the substrate in the respective zone 7a, 7b. The suction areas 7a, 7b can be defined and adjusted substantially freely not onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com