Processing center having automatic overturning function

A processing center and automatic turning technology, which is applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of inconvenient plate clamping, low production efficiency, and manpower consumption, and realize turning automation and operation Simple, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

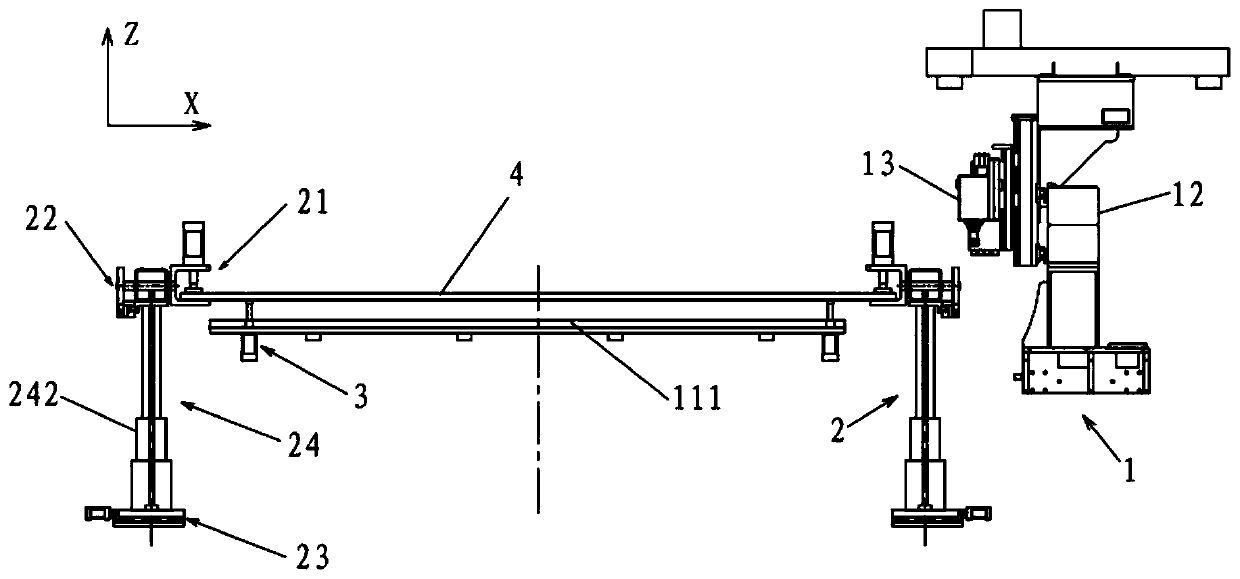

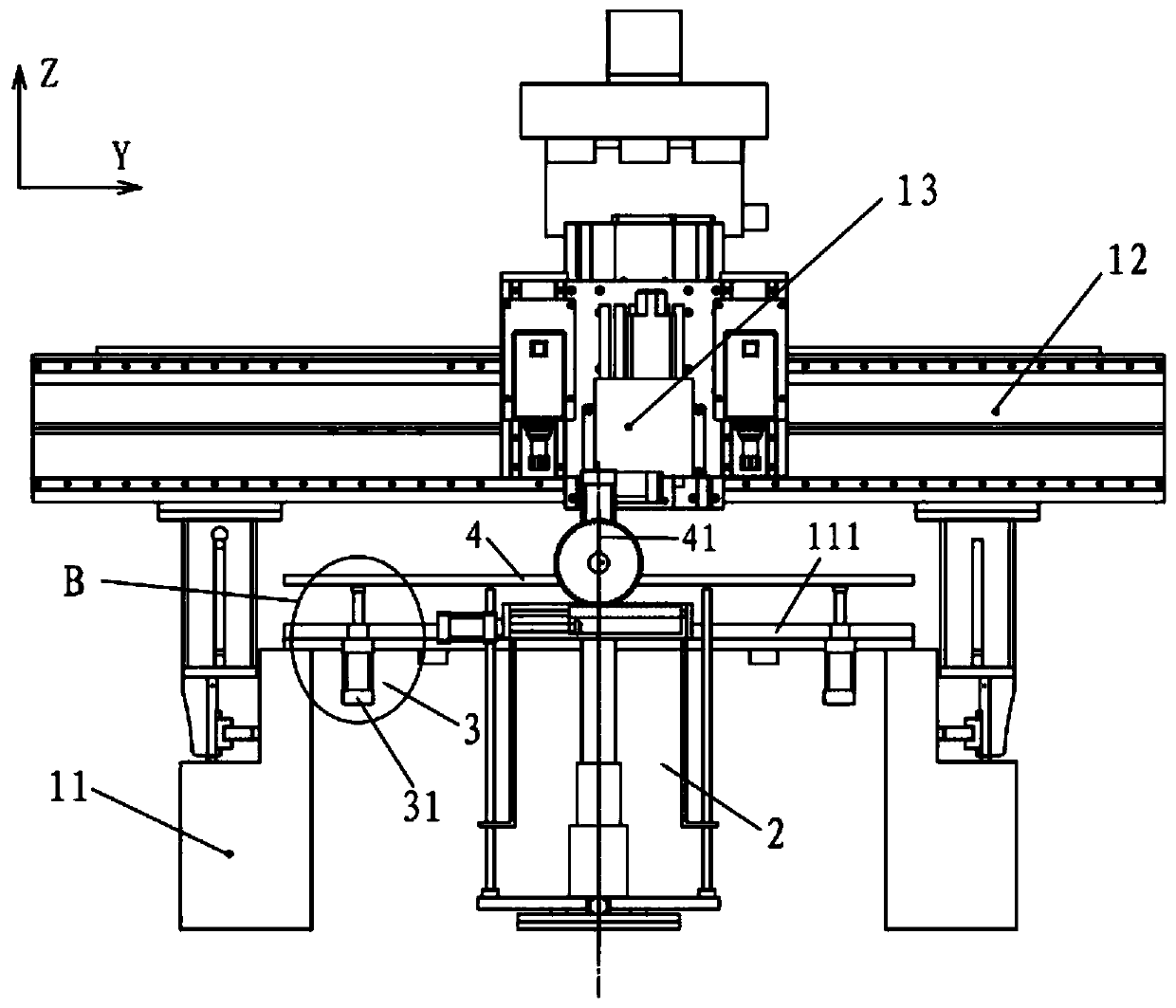

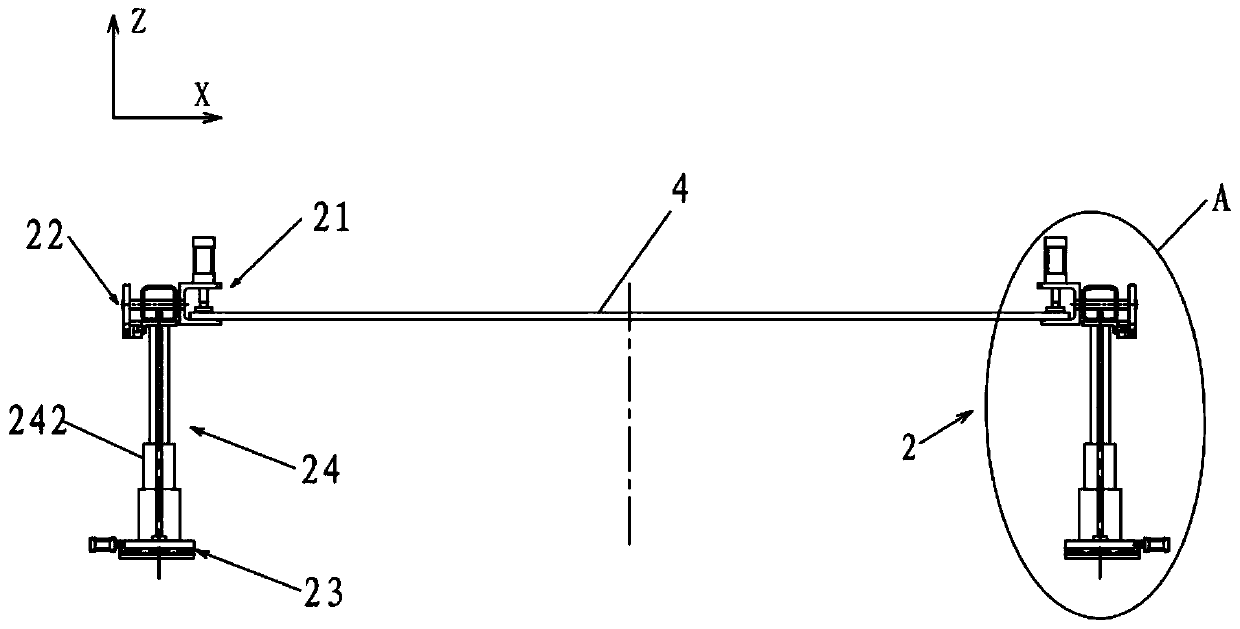

[0033] Such as Figure 1 to Figure 6 As shown, the machining center with automatic turning function includes machine tool 1, turning device 2 and jacking device 3, machine tool 1 includes frame 11, and frame 11 is provided with a workbench 111 for placing plate 4; turning device 2 is along X The axial direction is set under the middle part of the workbench 111;

[0034]Turning device 2 comprises clamping mechanism 21, rotating mechanism 22 and elevating mechanism 24; Elevating mechanism 24 comprises the lifting platform 241 of adjustable height; The clamping mechanism 21 includes a clamping plate 211 and a clamping block 212 for clamping the plate 4 , and is driven by the rotating mechanism 22 to turn over the plate 4 .

[0035] Further clarification, such as figure 1 , figure 2 and Figure 6 As shown, the machining center also includes a plurality of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com