Oblique gridding hot-molten felt

A hot-melt felt and grid technology, applied in the field of hot-melt felt, can solve the problems of hot-melt felt that is easy to break, increase packaging costs, and break into small pieces, so as to reduce production costs, reduce transportation costs, and resist bending The effect of empowerment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

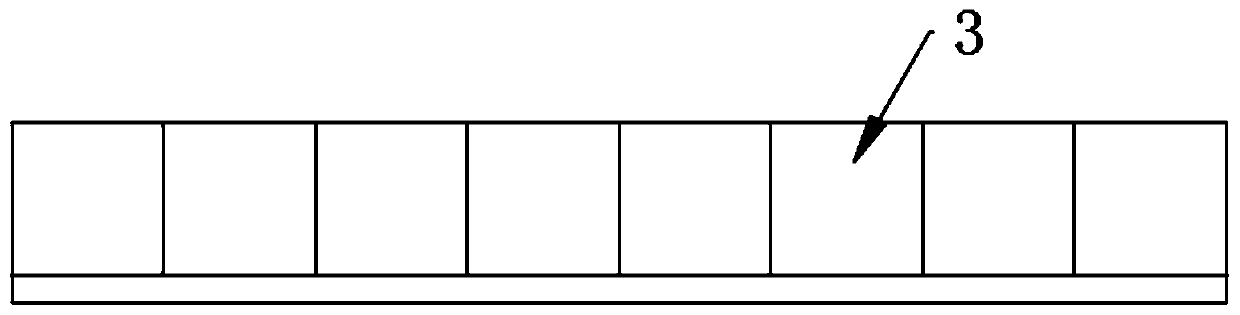

[0026] Embodiment 1: a kind of sandwich structure core material, such as figure 1 As shown, including plate 3, plate 3 is evenly cut into a plurality of small squares along the length direction and width direction, the bottom of plate 3 is adhered with oblique grid hot-melt felt by hot-melt adhesive, and the oblique grid hot-melt felt is not cutting.

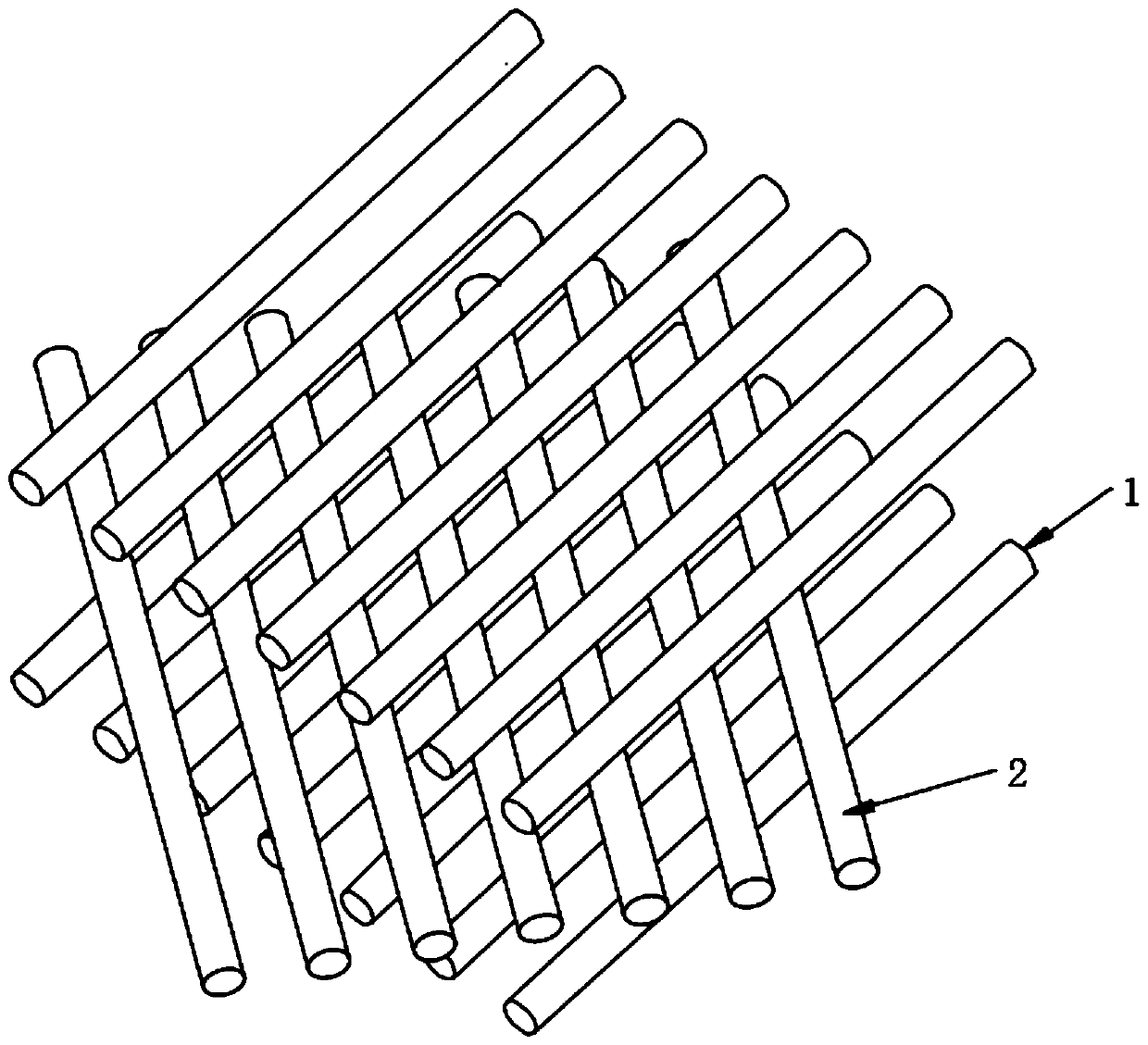

[0027] Such as figure 2 As shown, the diagonal grid hot-melt felt includes two layers of parallel warp yarns 1, and a layer of weft yarn 2 is laid between the two layers of warp yarns 1. The horizontal angle between the weft yarn 2 and the warp yarn 1 is 60°.

[0028] The length direction of the warp yarn 1 is the length direction of the mesh cloth, which ensures the normal production of the diagonal mesh cloth and will not be stretched and deformed during winding. If the diagonal mesh cloth is folded along the vertical direction of the warp yarn 1, the bending range of the two layers of weft yarn 2 inclined to the warp yarn ...

Embodiment 2

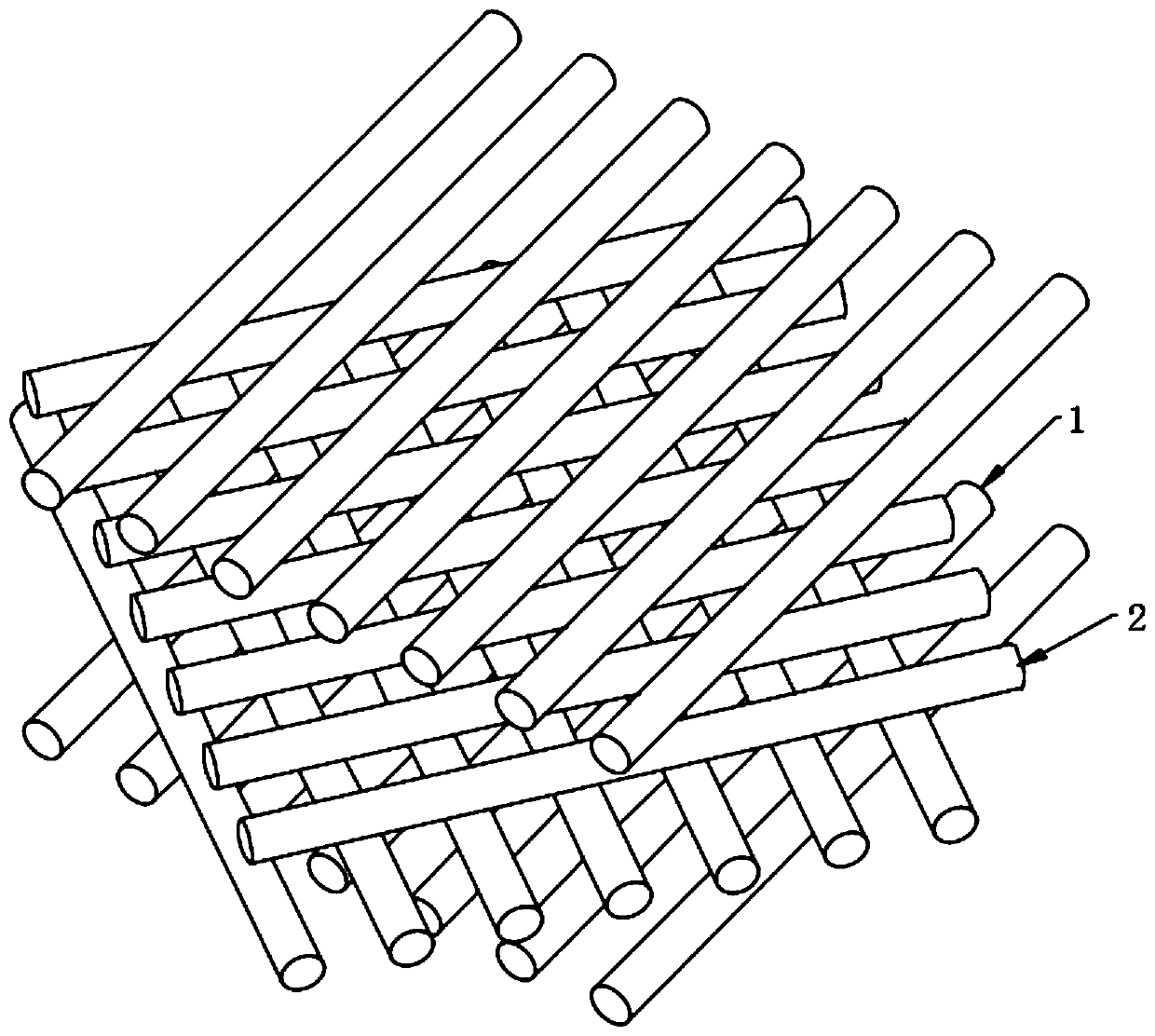

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the number of layers of weft yarns is different. Such as image 3 As shown, the oblique mesh hot-melt felt includes two layers of parallel warp yarns 1, and two layers of weft yarns 2 are laid in the middle of the two layers of warp yarns 1. The angle between one layer of weft yarns 2 and warp yarns 1 is 79°, and the other layer of weft yarns 2 and The included angle of warp yarn 1 is -79°, and the included angle in this implementation is set to 79°, but in actual production, it is not limited to 79°, as long as it is inclined weft yarn 2, it all belongs to the conventional variation of this technical solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com