Variable-helix-angle shaftless pumping propeller

A technology of helix angle and propeller, applied in the field of shaftless pump thrust, to achieve the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

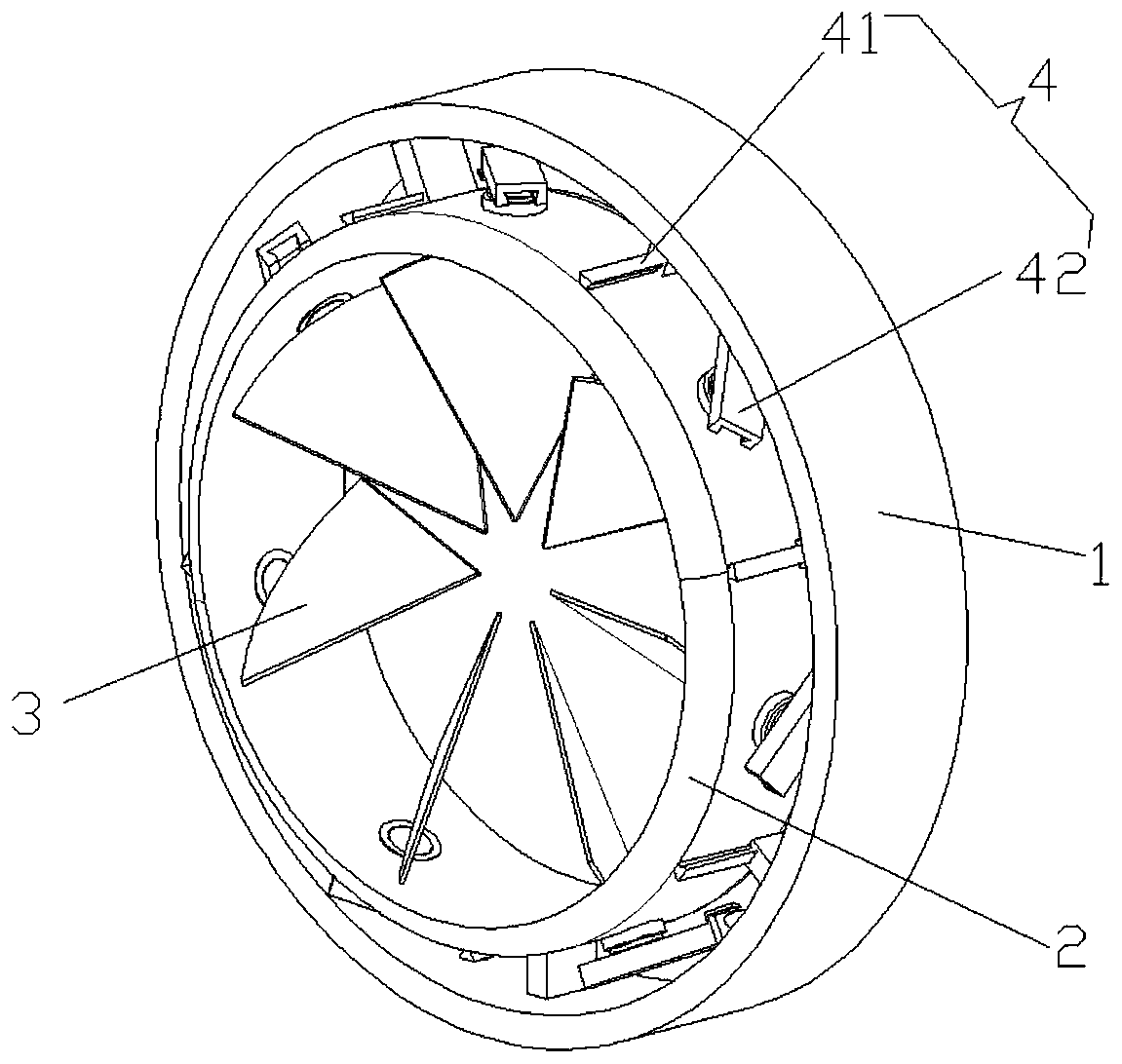

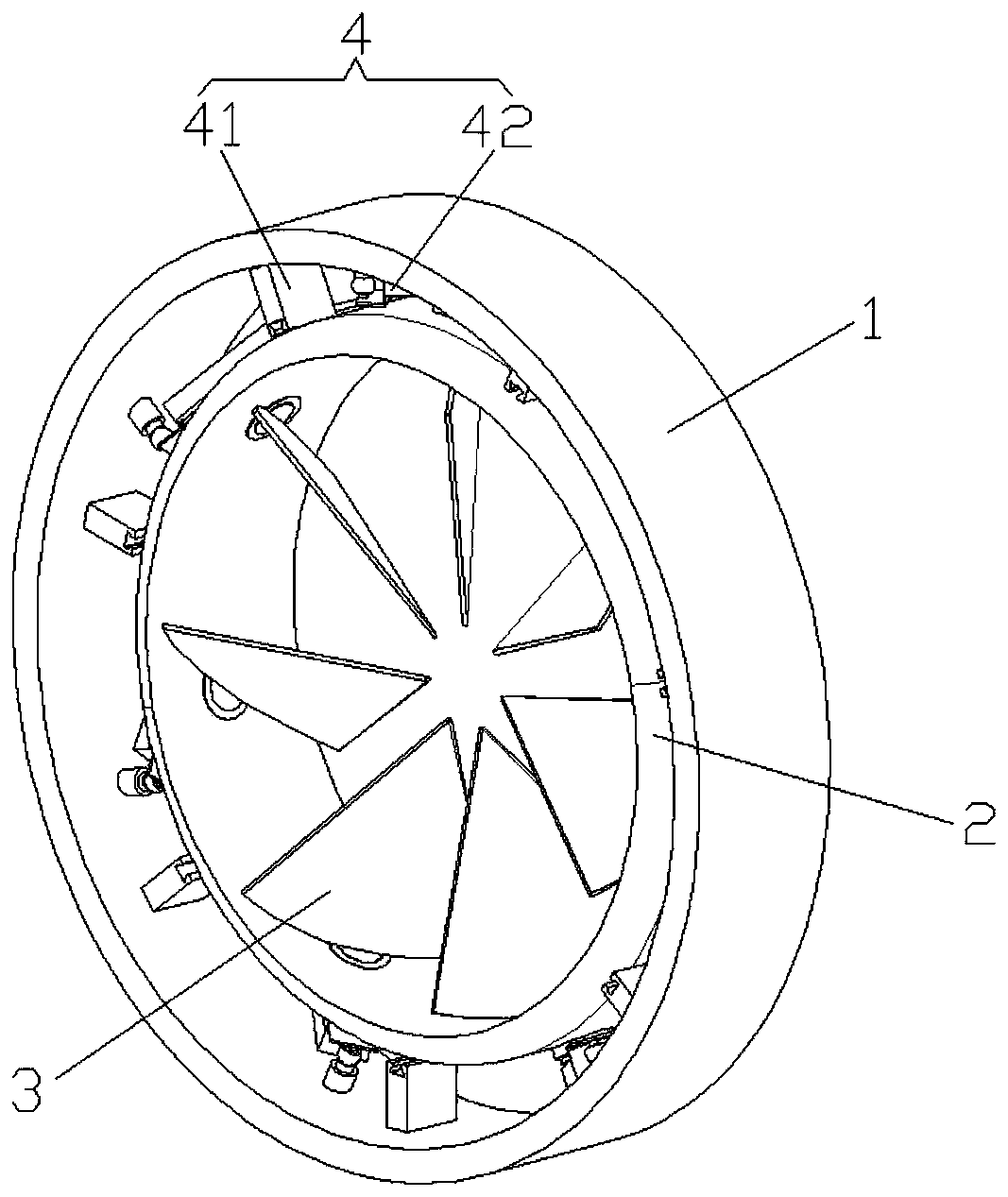

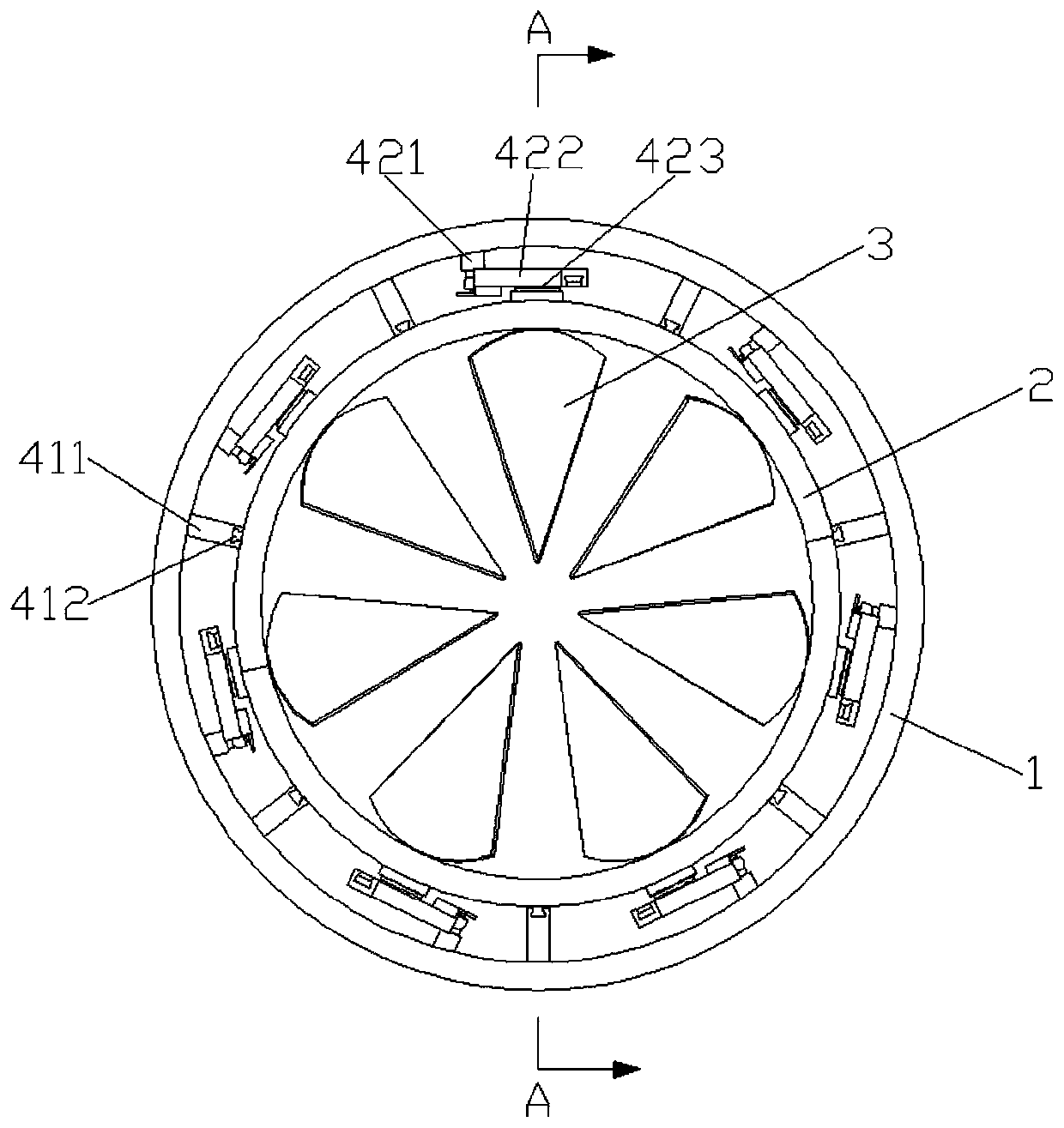

[0033] Such as Figure 1 to Figure 6 As shown, this embodiment provides a shaftless pump propeller with a variable pitch angle, which includes an outer ring 1 and an inner ring 2 arranged coaxially. The inner ring 2 is provided with a number of blades 3 for rotation, and all the The paddles 3 are evenly distributed along the circumference of the inner ring 2 .

[0034] The inner diameter of the outer ring 1 is greater than the outer diameter of the inner ring 2, so that there is a gap between the outer ring 1 and the inner ring 2, and a useful An adjustment mechanism 4 for adjusting the angle of the paddle 3 .

[0035] Specifically, each of the paddles 3 corresponds to one of the adjustment mechanisms 4, and when the outer ring 1 moves along its axial direction, the adjustment mechanism 4 controls the paddles 3 to follow the movement of the outer ring 1. Move and rotate synchronously, so as to switch between the propulsion state, the braking state and the reverse state of th...

Embodiment 2

[0043] This embodiment is a further improvement on the basis of the above-mentioned embodiment 1. In order to better realize the present invention, the following structure is particularly adopted:

[0044]The shaftless pump thruster with variable pitch angle also includes a driving device for driving the outer ring 1 to move along its axial direction.

[0045] The driving device includes a first hydraulic cylinder 5 and a push ring 6, the push ring 6 is arranged coaxially with the outer ring 1, and the outer ring 1 is located in the push ring 6 and rotates with the push ring 6 In cooperation, the piston rod of the first hydraulic cylinder 5 is connected and fixed to the ring wall of the push ring 6 through the first push rod 7 .

[0046] In this embodiment, the outer ring 1 and the push ring 6 can adopt the matching method between the inner ring and the outer ring of the ball bearing in the prior art, specifically, as Figure 7 As shown, the outer wall of the outer ring 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com