Preparation method of low-plasticizer-content or plasticizer-free grease

A plasticizer, oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of food pollution, carcinogenicity, teratogenicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

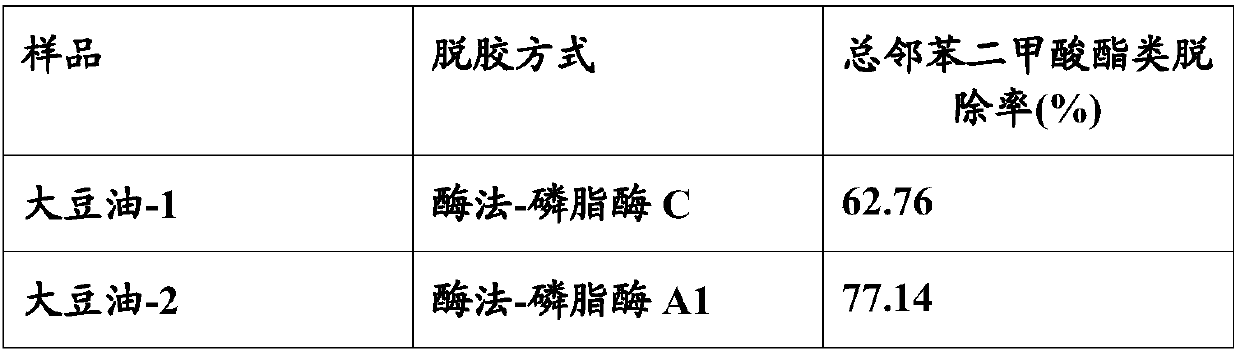

[0044] Example 1 Different phospholipase enzymatic degumming + magnesium silicate adsorption

[0045] Mix phospholipase C or A1 with water, and shear at 15000 rpm for 3 minutes (min). Then add the mixture of phospholipase and water to crude soybean oil for enzymolysis, the enzymolysis temperature is 40°C, the amount of enzyme added is 0.1% of the weight of the oil, the amount of water added is 10% of the weight of the oil, and the enzymolysis time is 4 Hour. Centrifugation was carried out after the enzymolysis was completed, and the centrifugation condition was 4500 rpm for 10 min. An enzyme-water mixture phase and an oil phase are obtained.

[0046] The oil phase obtained after the above centrifugal separation was contacted with the magnesium silicate adsorbent for 60 minutes, wherein the contact temperature was 100° C., the contact vacuum was 1013 mbar, and the magnesium silicate addition amount was 5% of the weight of the oil. After contacting for 60 minutes, carry out ...

Embodiment 2

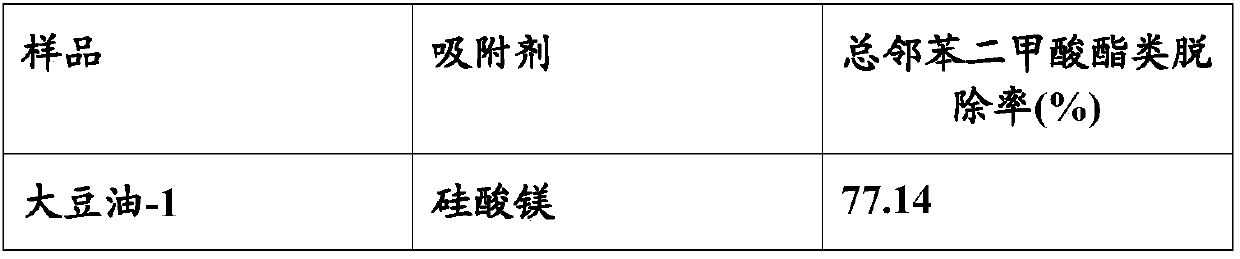

[0050] Example 2 Enzymatic degumming + different adsorbent adsorption

[0051] Mix phospholipase A1 with water, and cut at 15000rpm for 3min. Then add the mixture of phospholipase and water to crude soybean oil for enzymolysis, the enzymolysis temperature is 40°C, the amount of enzyme added is 0.1% of the weight of the oil, the amount of water added is 10% of the weight of the oil, and the enzymolysis time is 4 Hour. Centrifugation was carried out after the enzymatic hydrolysis was completed, and the centrifugation condition was 4500 rpm for 10 min. An enzyme-water mixture phase and an oil phase are obtained.

[0052] The oil phase obtained after the above centrifugal separation was contacted with the adsorbent for 60 minutes, wherein the contact temperature was 100° C., the contact vacuum was 1013 mbar, and the amount of the adsorbent added was 5% of the weight of the oil. After contacting for 60 minutes, carry out suction filtration under reduced pressure to separate th...

Embodiment 3

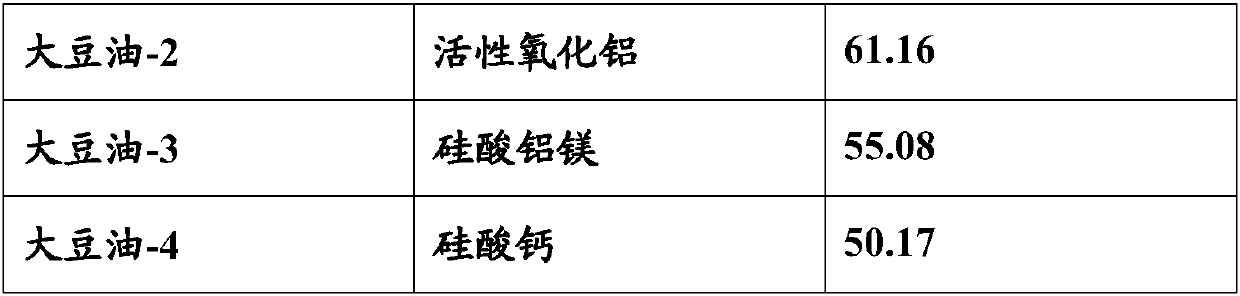

[0057] Example 3 Enzymatic degumming + magnesium silicate adsorption under different conditions

[0058] Mix phospholipase A1 with water, and cut at 15000rpm for 3min. Then add the mixture of phospholipase and water to the soybean oil for enzymolysis, the enzymolysis temperature is 40°C, the amount of enzyme added is 0.01% of the weight of the oil, the amount of water added is 10% of the weight of the oil, and the time of enzymolysis is 4 hours. Centrifugation was carried out after the enzymatic hydrolysis was completed, and the centrifugation condition was 4500 rpm for 10 min. An enzyme-water mixture phase and an oil phase are obtained.

[0059] The oil phase obtained after the above centrifugation is contacted with different amounts of magnesium silicate adsorbents under vacuum conditions (vacuum degree is 5mbar), and after the end, vacuum filtration is carried out to separate the solid and liquid, and the obtained liquid is the treated Soybean oil.

[0060] The content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com