Vacuum water-absorbing prepreg tank for wet cloth hot alkali straight roll mercerizing machine and its processing method

A technology of vacuum water absorption and mercerizing machine, which is applied to the mercerizing of fabrics with indefinite lengths, liquid/gas/steam removal by air jet method, heating/cooling of fabrics, etc., which can solve the problem of poor quality, prone to wrinkle and expansion of fabrics, and low cooling efficiency In other problems, to achieve the effect of increasing cleanliness, reducing wrinkles, increasing reflection and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

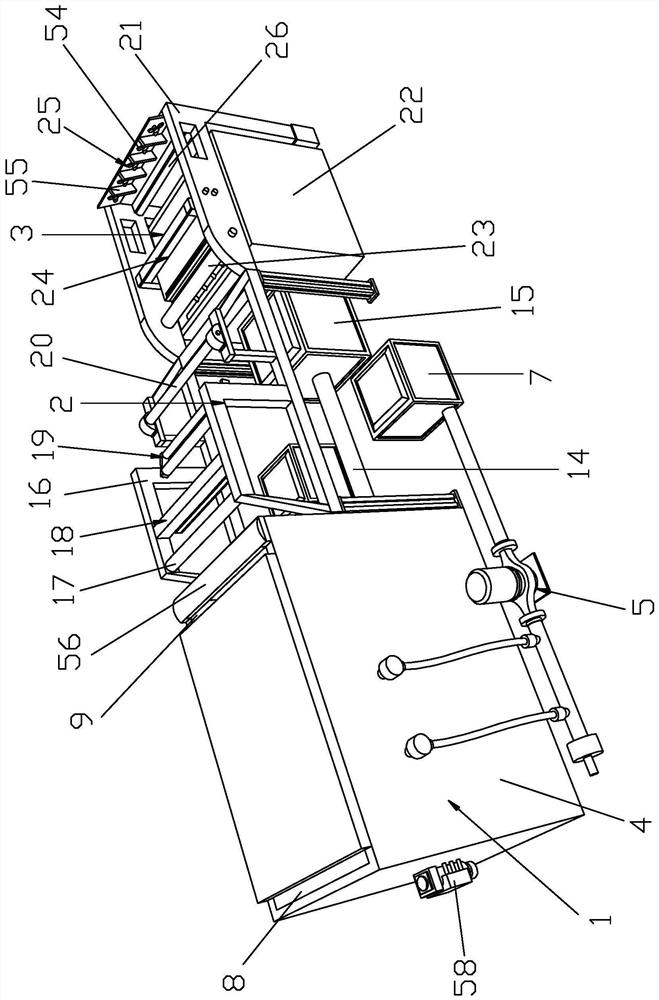

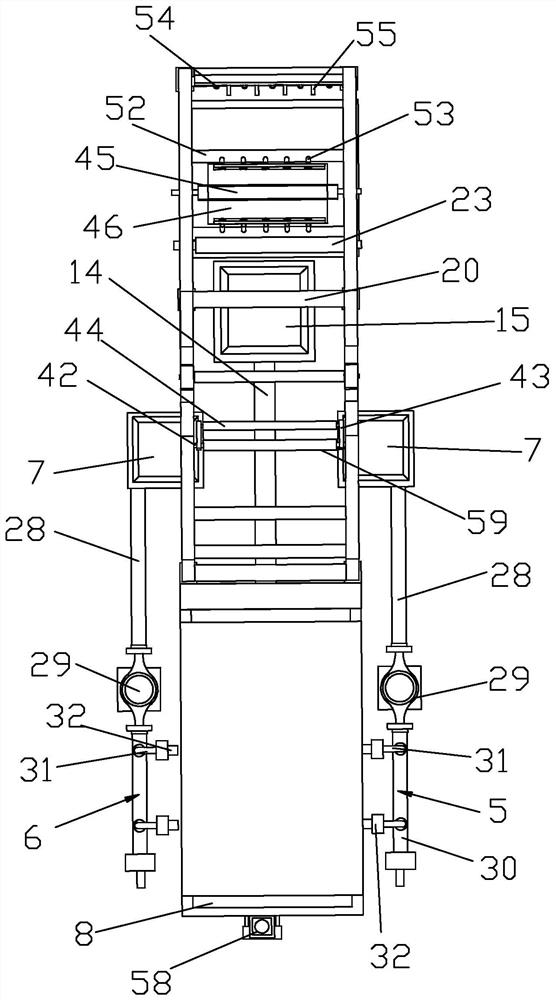

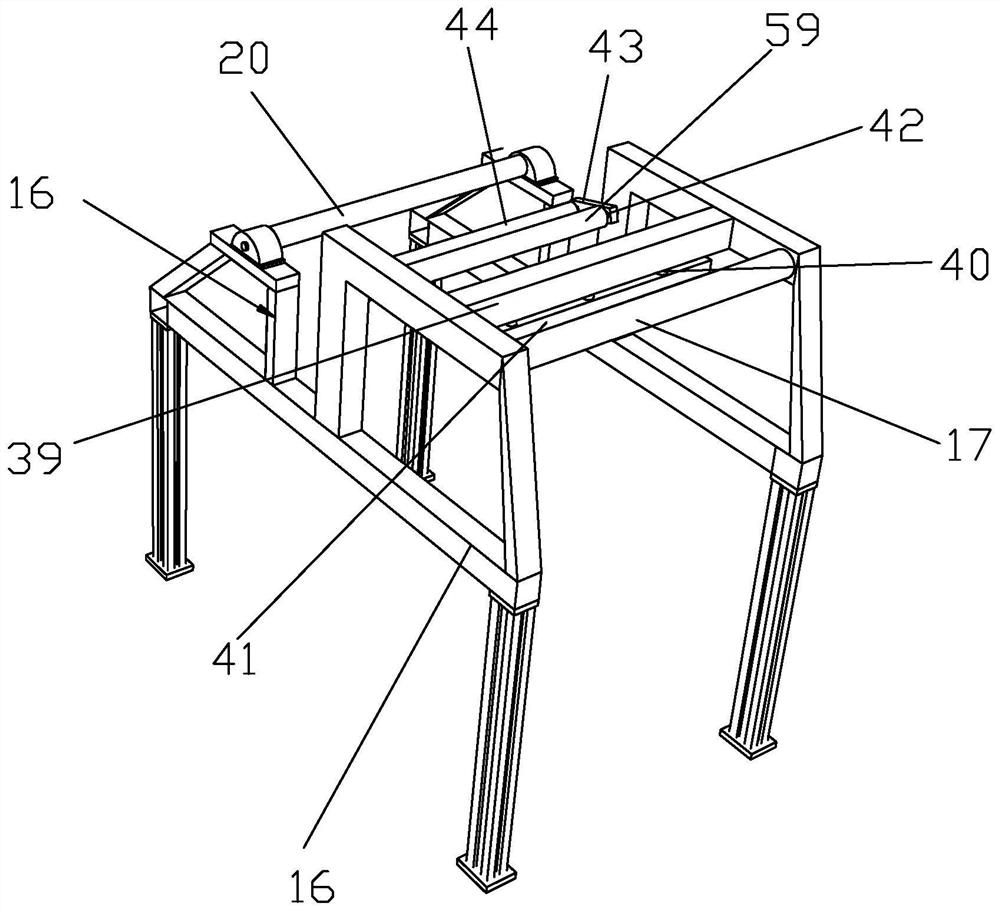

[0041] Such as Figure 1 to Figure 6 As shown, it is a vacuum water-absorbing prepreg tank for a wet cloth hot alkali straight roll mercerizing machine of the present invention, including a prepreg device 1, a padding device 2 and a cooling device 3, the prepreg device 1 is connected with the padding device 2, and the padding device 2 Connected with the cooling device 3, the prepreg device 1 includes a tank body 4, the two ends of the tank body 4 are provided with a light alkali delivery device 5 and a concentrated alkali delivery device 6, and both the light alkali delivery device 5 and the concentrated alkali delivery device 6 are equipped with a storage tank. Liquid pool 7, the top of the tank body 4 is provided with a cloth inlet tank 8 and a cloth outlet tank 9, the inside of the tank body 4 is provided with a partition plate 10 and a first rotating roller 11, and the bottom of the partition plate 10 is provided with an alkali mixing Device 12 and heating pipe 13, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com