Tower crane foundation and construction method thereof

A tower crane foundation and foundation technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problem that the tower crane foundation cannot be reused, and achieve the effects of shortening the construction period, improving construction efficiency, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

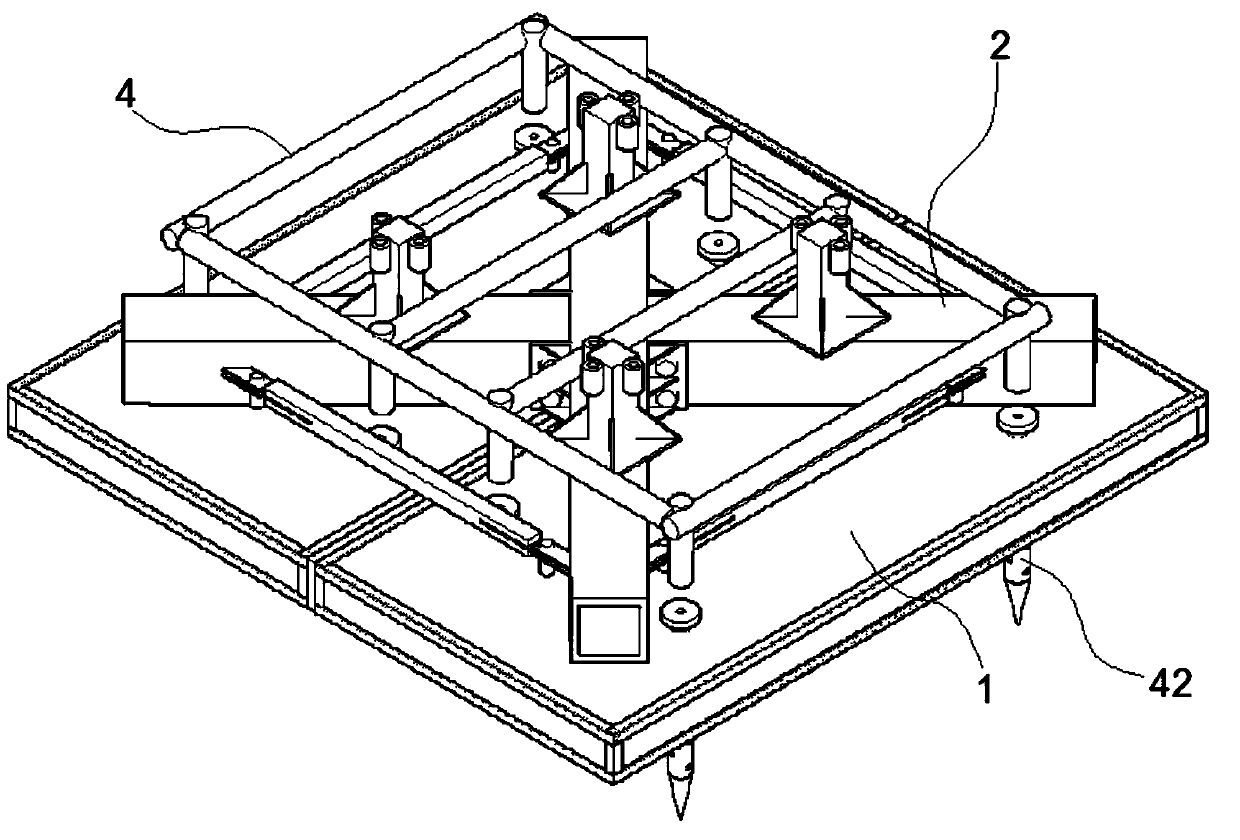

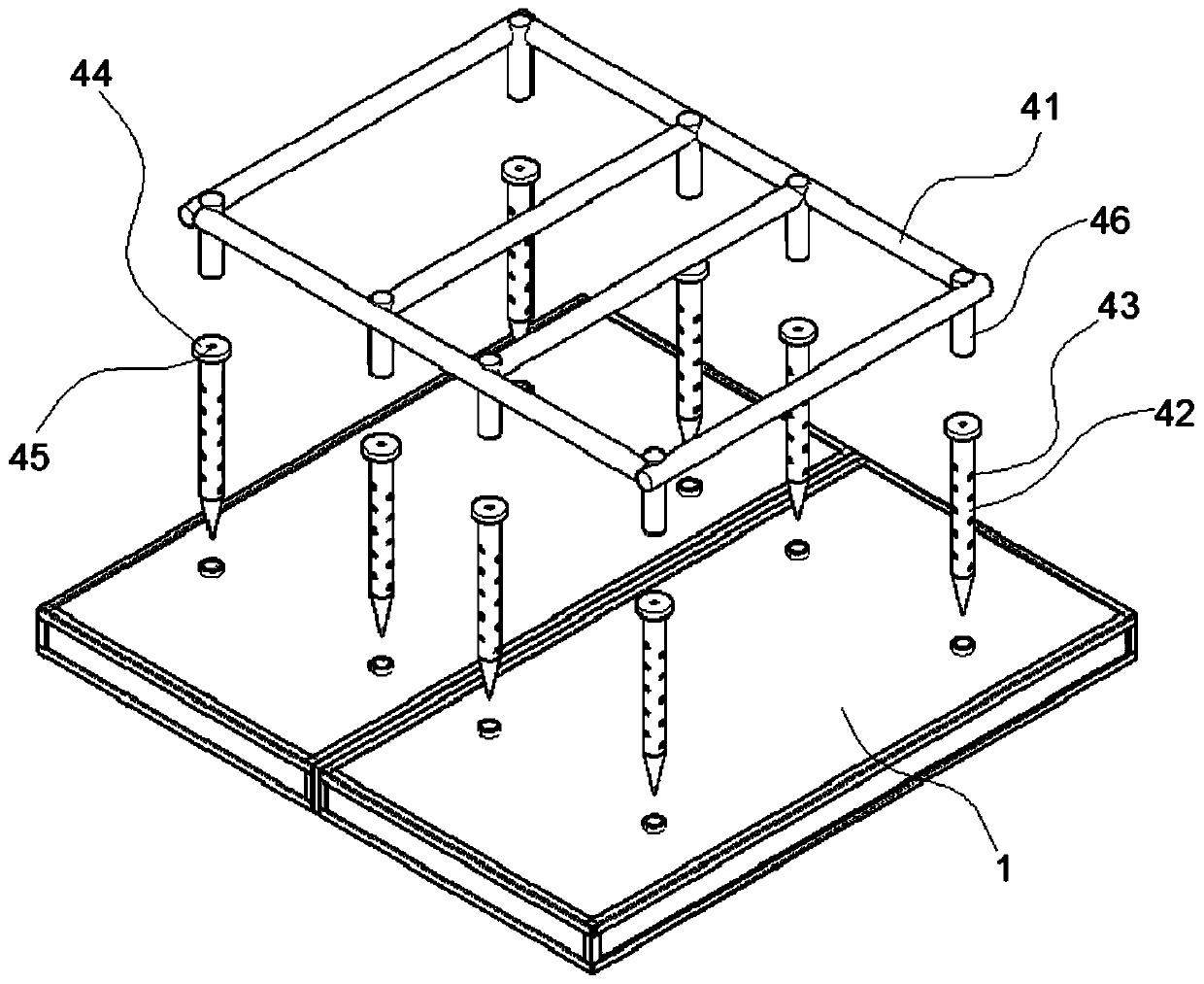

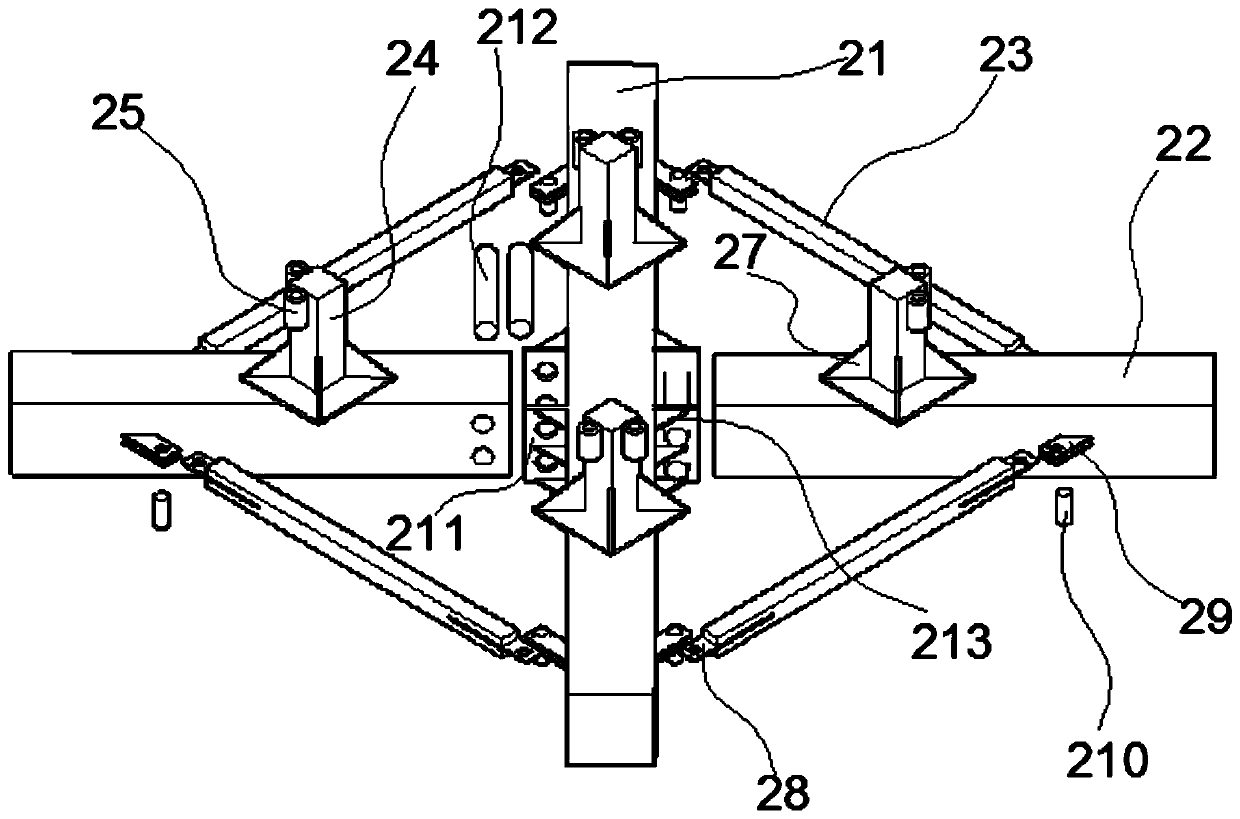

[0030] The tower crane foundation of the present invention, such as figure 1 and figure 2 As shown, it includes a concrete support plate 1, a steel structure foundation 2 and a positioning frame 4, a concrete support plate 1, a steel structure foundation 2 and a positioning frame 4, and the concrete support plate 1 is used to make the gravity of the tower crane, the steel structure foundation 2 and other components even. The ground is transferred to the ground to ensure the stability of the steel structure foundation 2, tower cranes and other equipment. The concrete support plate 1 can be an integral plate, as a preferred embodiment: the concrete support plate 1 has a thickness of about 400mm, and is formed by splicing multiple concrete plates, and the edge of each concrete plate is provided with a protective angle steel. Filling material is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com