Red copper integrated splitter

A shunt and red copper technology, applied in the field of copper integrated shunt, can solve the problems of difficult processing and achieve the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

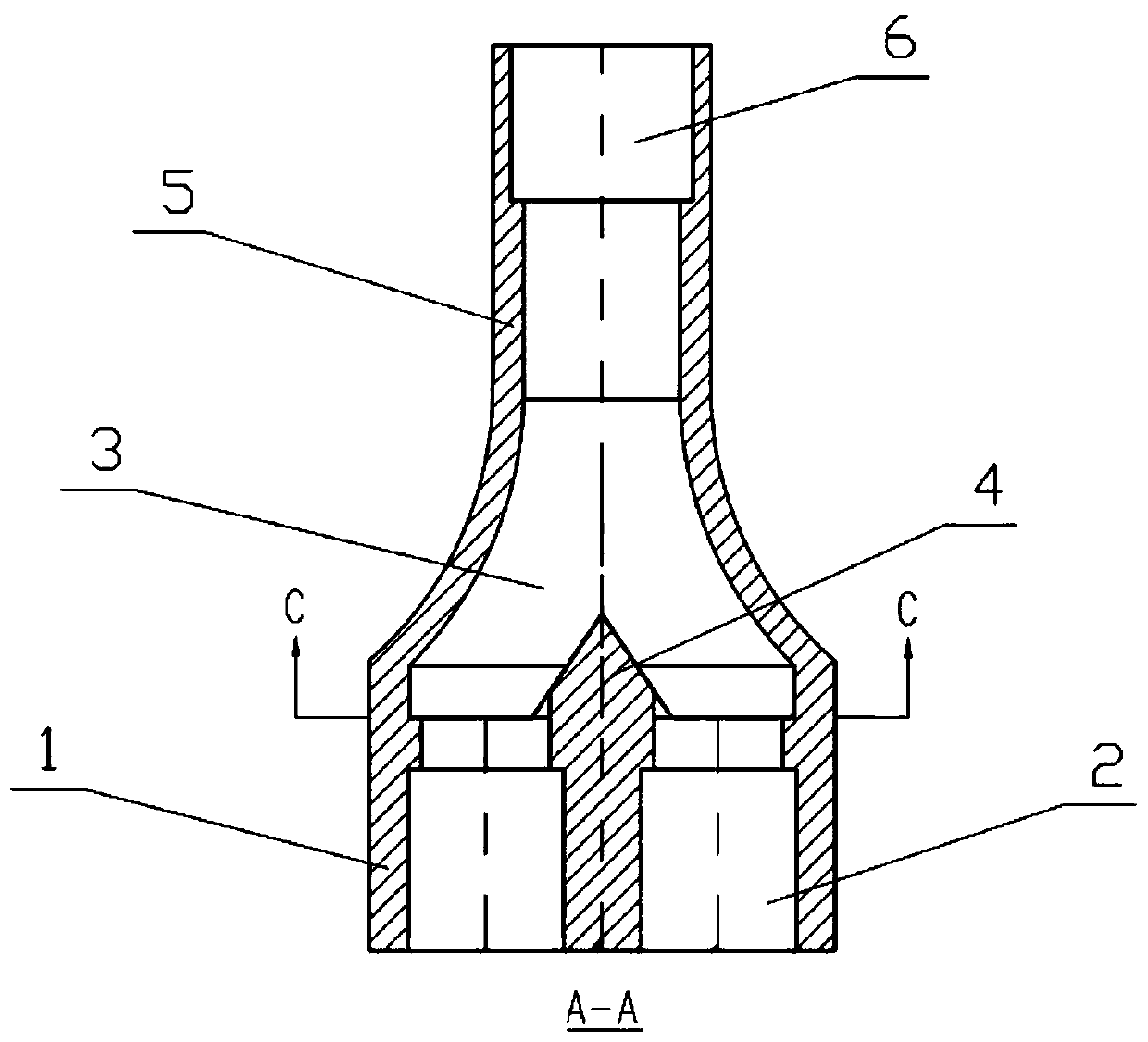

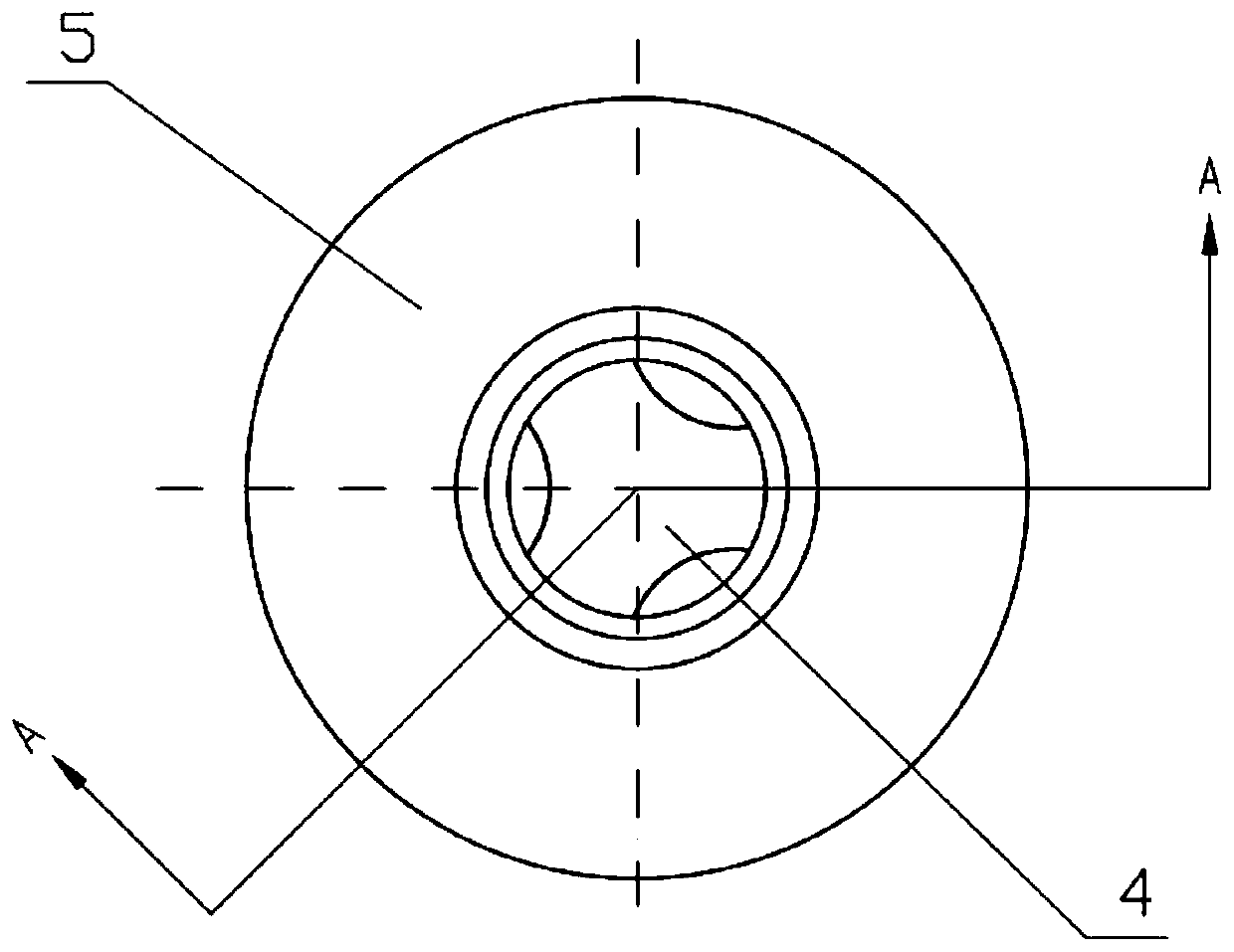

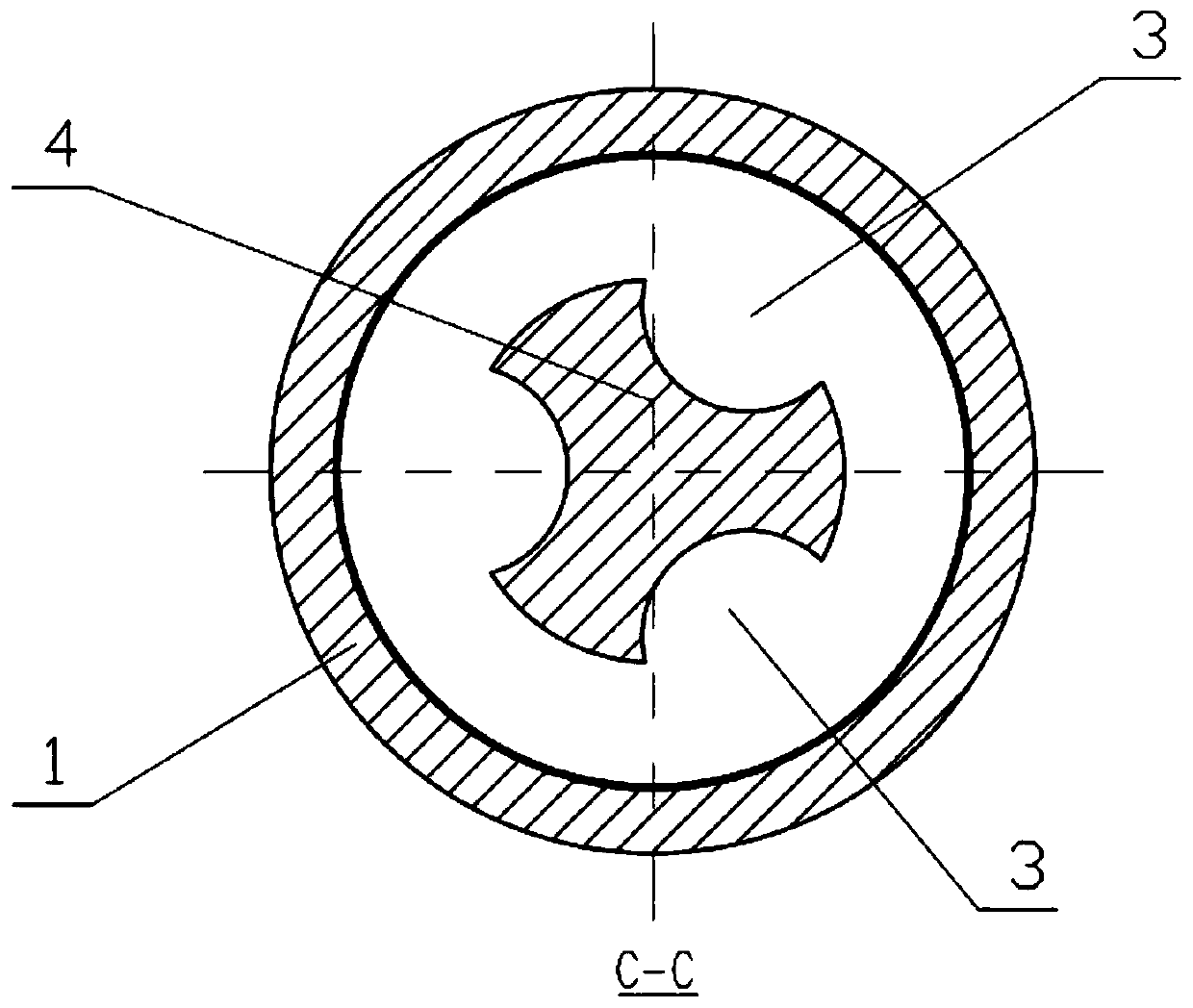

[0018] Combine below Figure 1-4 Describe this embodiment, a red copper integrated diverter, including a diverter housing 1, a diversion tank 3, a diversion cone 4 and a diversion inlet housing 5, the diverter housing 1, a diversion cone 4 and a diversion inlet housing 5 are integrated Forming, one end of the shunt housing 1 is narrowed to form the shunt inlet housing 5, the shunt housing 1 is fixedly connected with the shunt cone 4, the shunt housing 1 is fixedly connected with the shunt cone 4, the shunt cone 4 and the shunt inlet The inner hole of the shell 5 forms a V-shaped splitter groove 3; the splitter shell 1, the splitter cone 4 and the splitter inlet shell 5 can be integrally formed to reduce the difficulty of processing, and the splitter shell 1 is fixedly connected with the splitter cone 4 A V-shaped flow distribution groove 3 is formed to realize the function of flow distribution.

specific Embodiment approach 2

[0019] Combine below Figure 1-4 Describe this embodiment, this embodiment will further explain Embodiment 1, the shunt casing 1, the shunt cone 4 and the shunt inlet casing 5 are all made of red copper; red copper has good ductility, and can effectively reduce the of lead content.

specific Embodiment approach 3

[0020] Combine below Figure 1-4 Describe this embodiment, this embodiment will further explain the second embodiment, the copper integrated flow divider also includes a flow divider outlet 2, three flow divider outlets 2 are evenly arranged on the bottom of the flow divider shell 1, and three flow divider outlets 2 Both communicate with the distribution tank 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com