Sparse representation method for extracting weld characteristic guided wave defect echo signal characteristics

A technology of sparse representation and defect echo, applied in the field of defect detection, can solve the problems of non-stationary guided wave signal and difficult to accurately extract defect features, and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

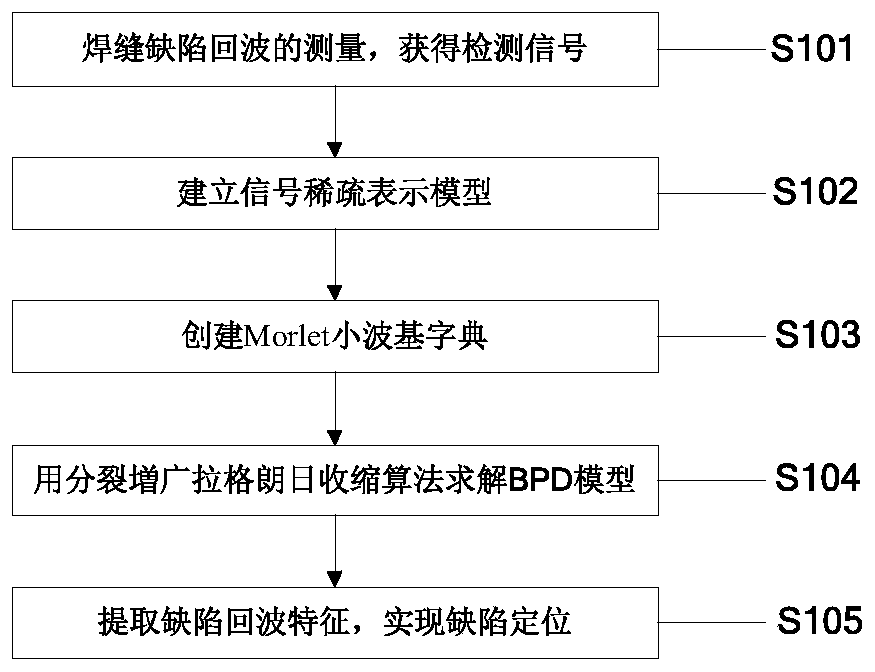

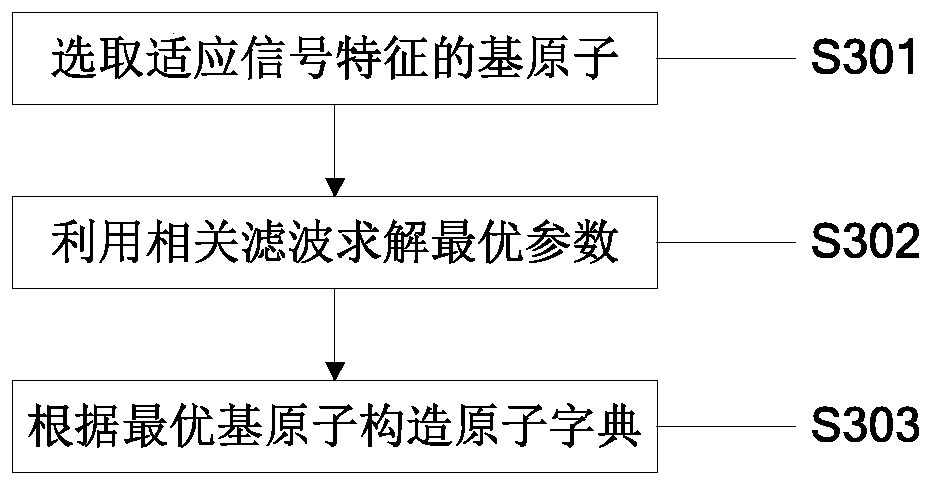

Method used

Image

Examples

Embodiment

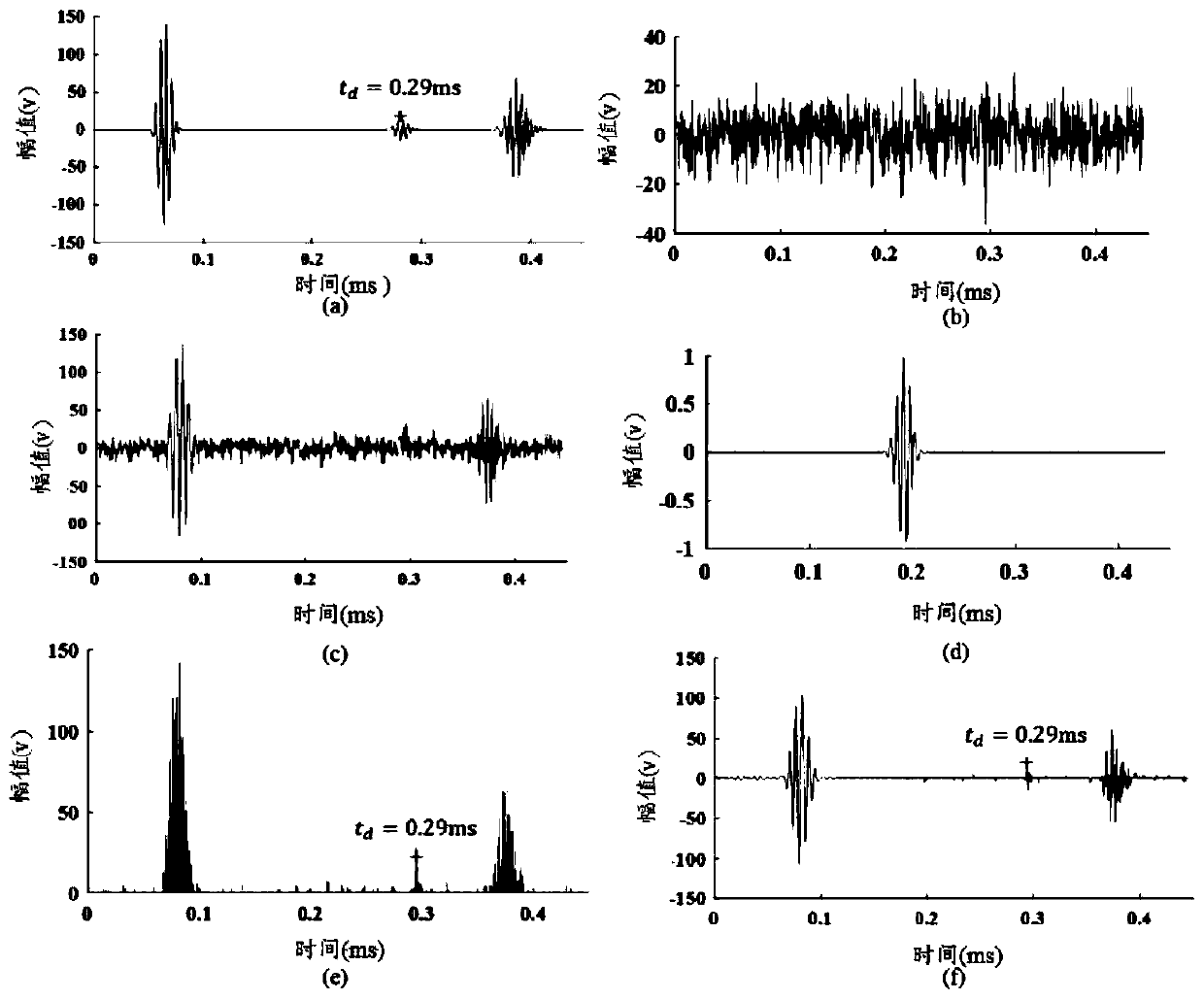

[0108] Embodiment: analyze the data that experiment obtains

[0109] During the experiment, as shown in the figure, the signal generator (DG4062) generates a 5-period Hanning window modulation waveform with a center frequency of 200-250kHz to excite the excitation sensor at the top of the weld to form a SH1 mode in the weld, and the signal passes through The propagation of the weld seam to be measured is received by the receiving sensor, amplified by a preamplifier with a gain of 40dB, and sent to a digital oscilloscope (DS2102A) for observation and display.

[0110] Figure 5 (a) shows the echo signal with defects, obviously the defect echo cannot be obtained from Figure 5 identified in (a). The process of applying the method of the present invention to the echo signal is the same as the analysis method of the above-mentioned simulation study. Here we set λ=11, μ=3, and the number of iterations of the split-augmented Lagrangian contraction algorithm is 50. Analysis resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com