Insulation fault positioning device and method applied to insulated tubular busbar

A technology of insulation faults and insulating tubes, applied in the field of fault location of insulating tubular busbars, which can solve the problems of fluctuations and the influence of on-site environmental factors, single monitoring means, and the inability to accurately grasp the insulation status of insulating tubular busbars, etc., to achieve fast and accurate positioning instructions , Reduce the effect of dielectric loss measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

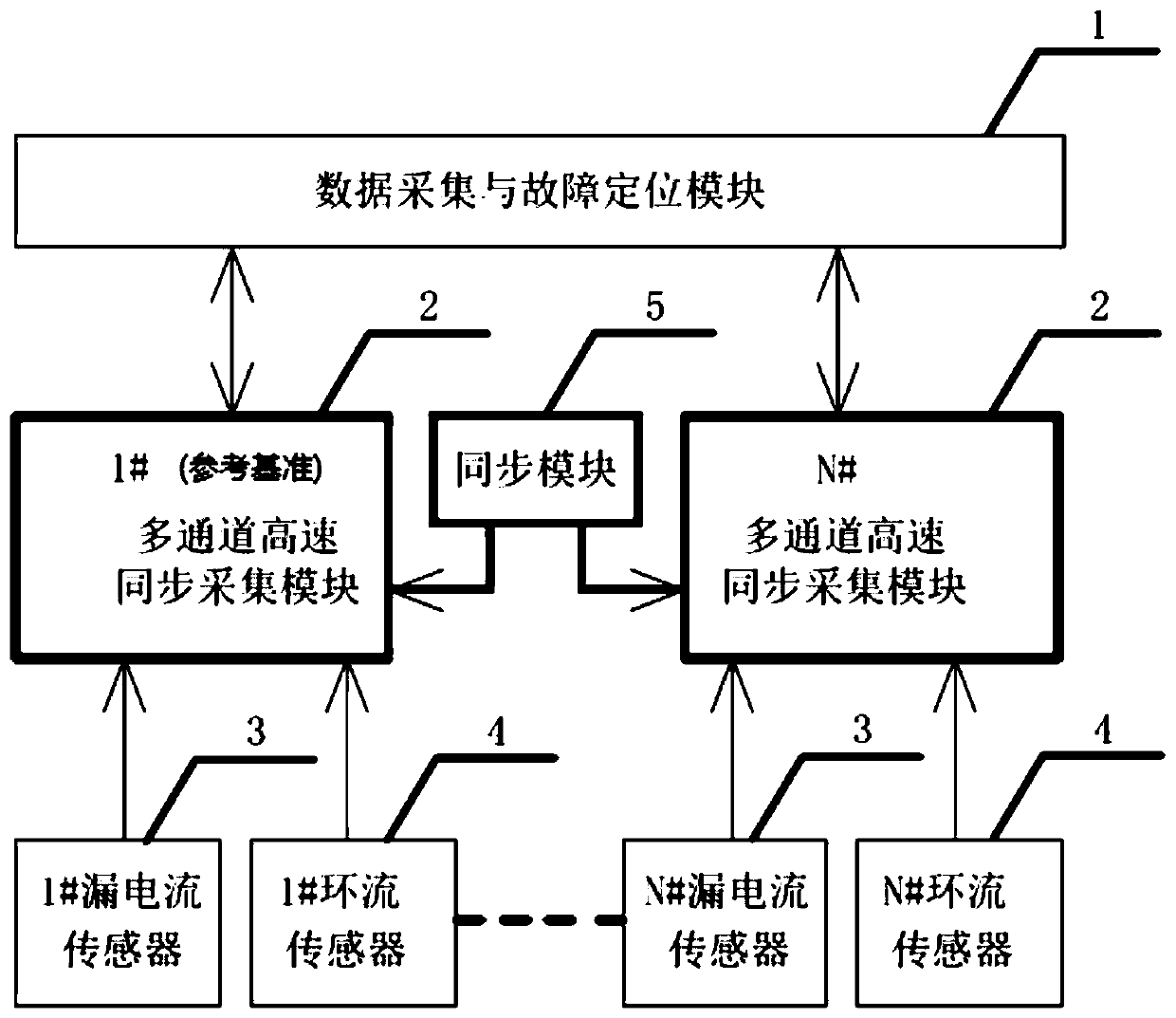

[0037] Such as figure 1 As shown, the present invention provides a device for insulation fault location of insulating tubular busbars, including a leakage current sensor 3 , a circulating current sensor 4 , a multi-channel high-speed synchronous acquisition module 2 , a data acquisition and fault location module 1 , and a synchronization module 5 .

[0038] The leakage current sensor 3 is installed under the grounding down conductor of each section of the insulating tubular busbar ground screen, and uses the principle of current mutual inductance to collect the leakage current of the main insulator of the insulating tubular busbar; the leakage current sensor 3 adopts a multi-layer nested magnetic shield Structural design, which has good anti-electromagnetic interference effect against the strong magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com