Three-dimensional memory and manufacture method thereof

A manufacturing method and memory technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of poor retention characteristics of three-dimensional memory, and achieve the effect of improving retention characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

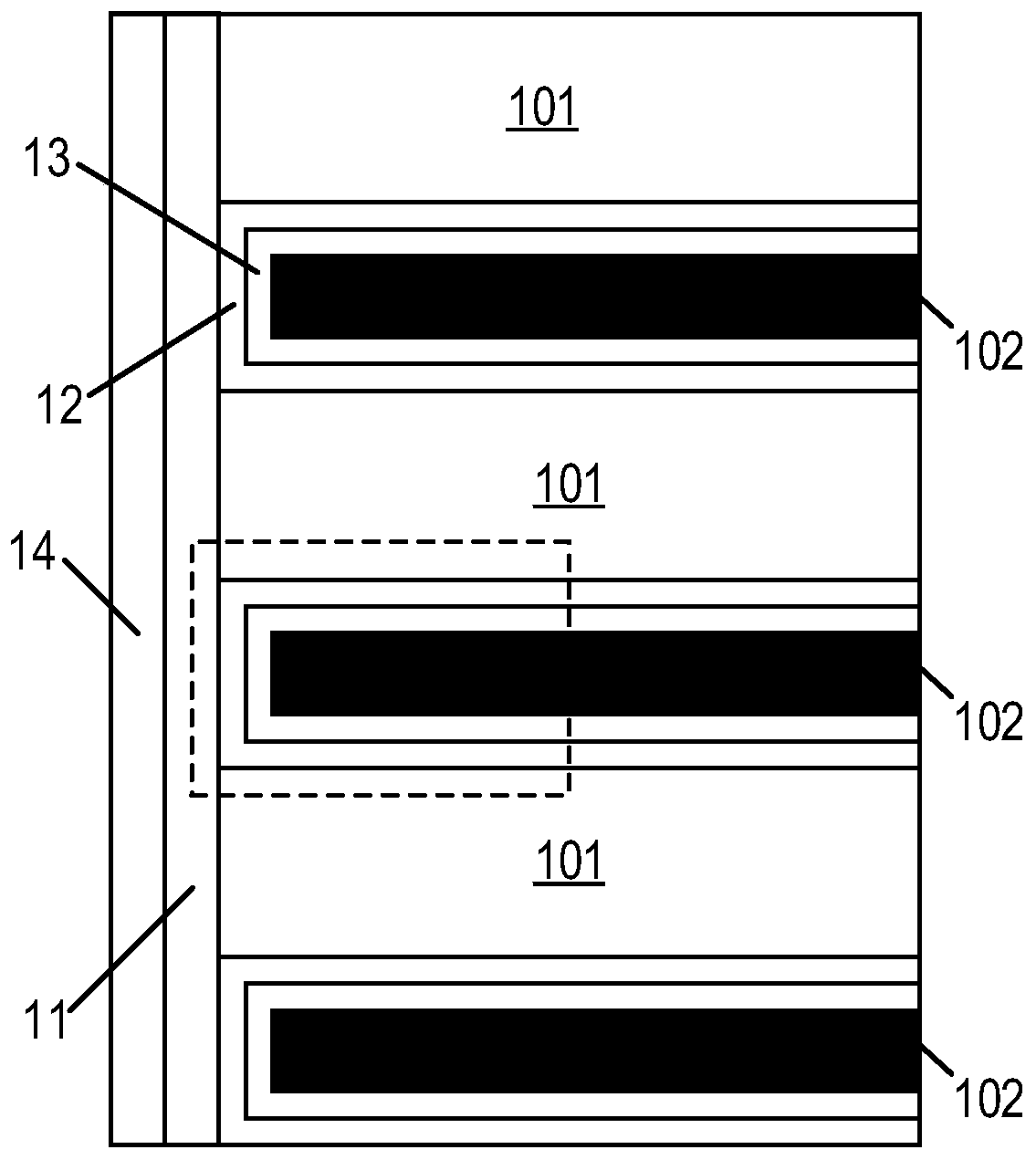

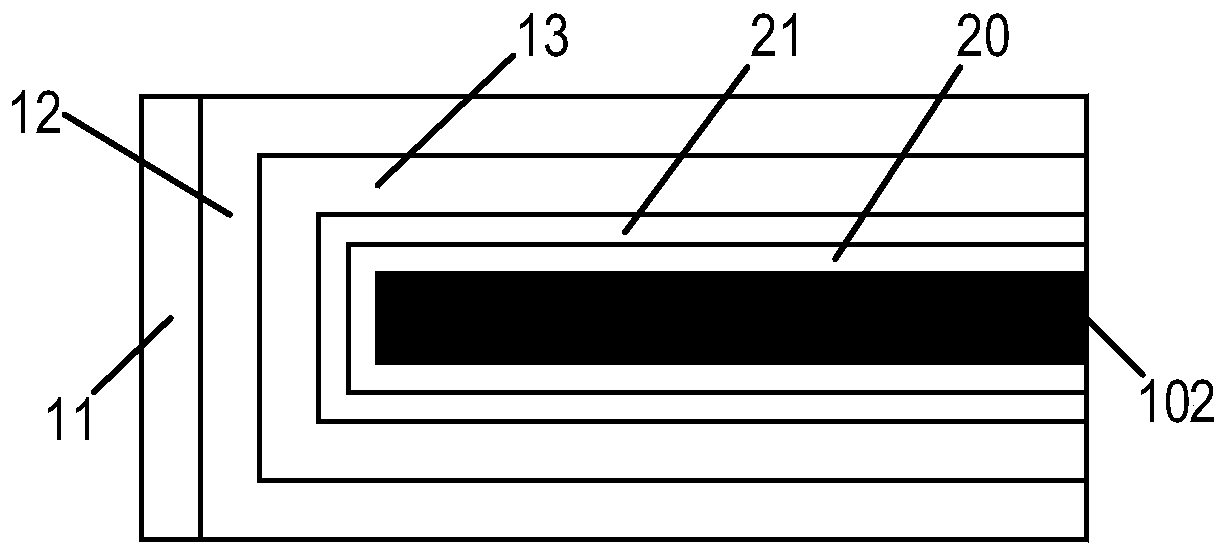

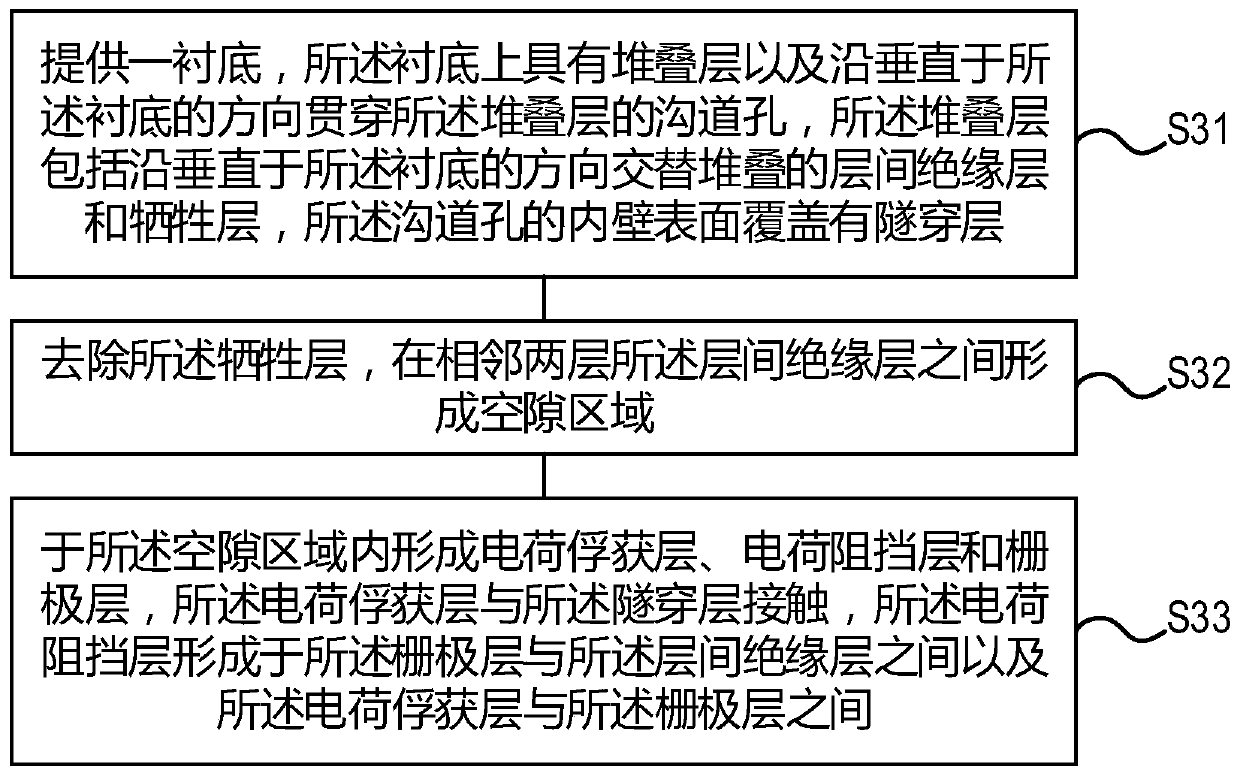

[0046] The specific implementation of the three-dimensional memory and its manufacturing method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] In the existing three-dimensional memory such as 3D NAND, the storage string as its key storage structure is composed of a blocking layer, a charge trapping layer, a tunneling layer and channel layer. After sequentially depositing the blocking layer, the charge trapping layer and the tunneling layer in the channel hole, the blocking layer, the charge trapping layer and the tunneling layer are etched to open The epitaxial semiconductor layer is exposed at the bottom of the channel hole; then the channel layer is deposited to form a channel path, thereby controlling the charge storage function of the three-dimensional memory.

[0048] As the market's requirements for storage density continue to increase, the number of stacked layers in the stacked structure in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com