Inorganic fiber sheet, honeycomb molded body and honeycomb filter

An inorganic fiber, honeycomb-type technology, applied in the direction of inorganic chemistry, synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, etc., can solve the problem of light weight or thinning, and difficulty in obtaining strength of bio-soluble ceramic fibers, etc. Problems, excellent processability and sufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

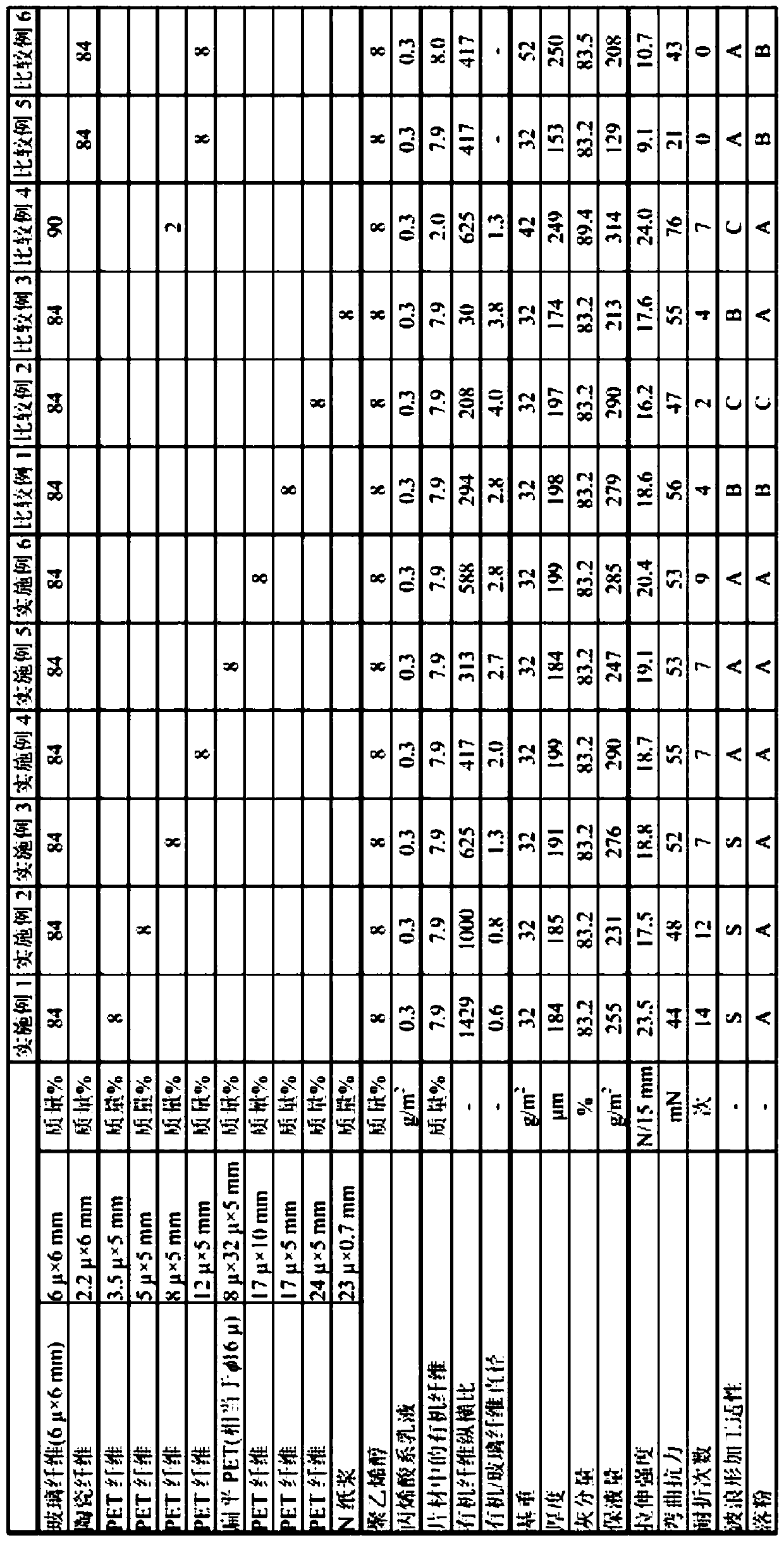

[0101] Hereinafter, although an Example and a comparative example demonstrate this invention more concretely, this invention is not limited to a following example.

[0102]

[0103] (base weigh)

[0104] The obtained inorganic fiber sheet was measured based on JIS P8124.

[0105] (thickness)

[0106] The obtained inorganic fiber sheet was measured based on JIS P8118.

[0107] (Tensile Strength)

[0108] The obtained inorganic fiber sheet was measured by a method according to JIS P 8113 using a Tensilon type tensile tester (manufactured by ORIENTEC).

[0109] (bending resistance)

[0110] The obtained inorganic fiber sheet was measured by the method based on ISO2493 using the bending strength tester (BENDING RESISTANCE TESTER) (made by L&W company).

[0111] (folding times)

[0112] For the obtained inorganic fiber sheet, according to the JIS P 8115 flexural strength test method, the MIT (Massachusetts Institute of Technology, MIT) testing machine was used to calculate ...

Embodiment 2

[0134] The organic fibers were changed to polyethylene terephthalate fibers (diameter: 5 μm, length: 5 mm, aspect ratio: 1000), and the basis weight, thick inorganic fiber sheet.

[0135] Thereafter, measurement and evaluation were performed in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 3

[0137] The organic fibers were changed to polyethylene terephthalate fibers (diameter: 8 μm, length: 5 mm, aspect ratio: 625), and the basis weight, thick inorganic fiber sheet.

[0138] Thereafter, measurement and evaluation were performed in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com