Sensor element for detecting particles of a measuring gas in a measuring gas chamber

A technology of a sensor element and a gas chamber, which is applied in the field of sensor elements used to sense the particles of the measurement gas in the measurement gas chamber, and can solve the problems of superposition of measurement effects, difficulty in realizing self-monitoring of soot sensor, failure of electrical functionality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

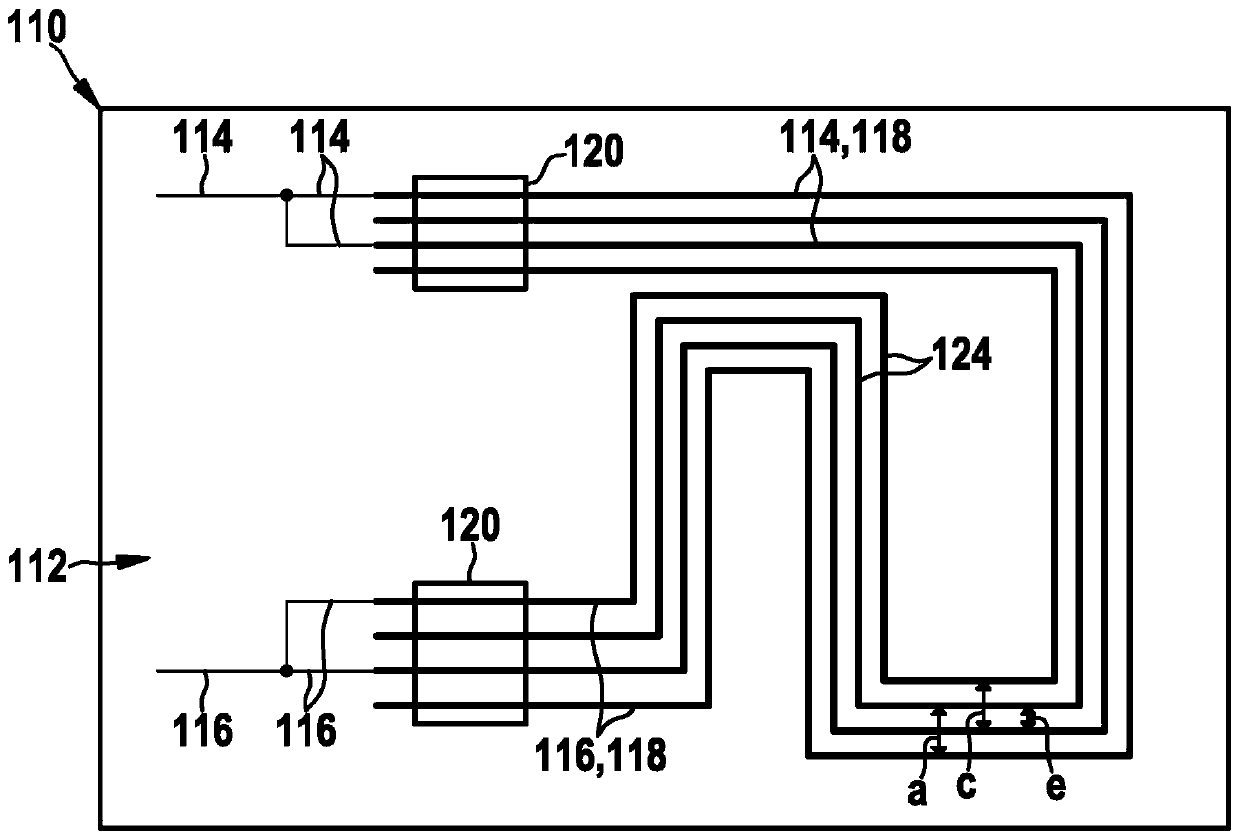

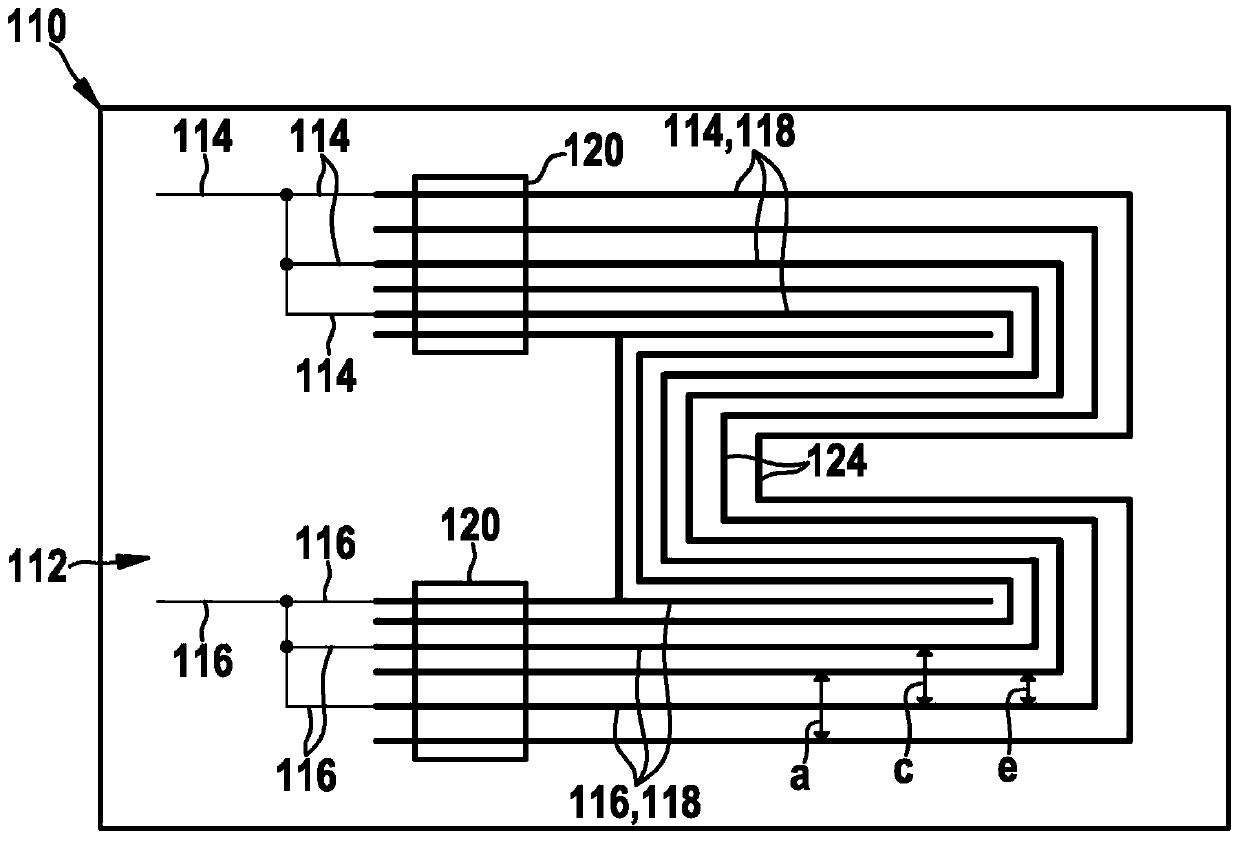

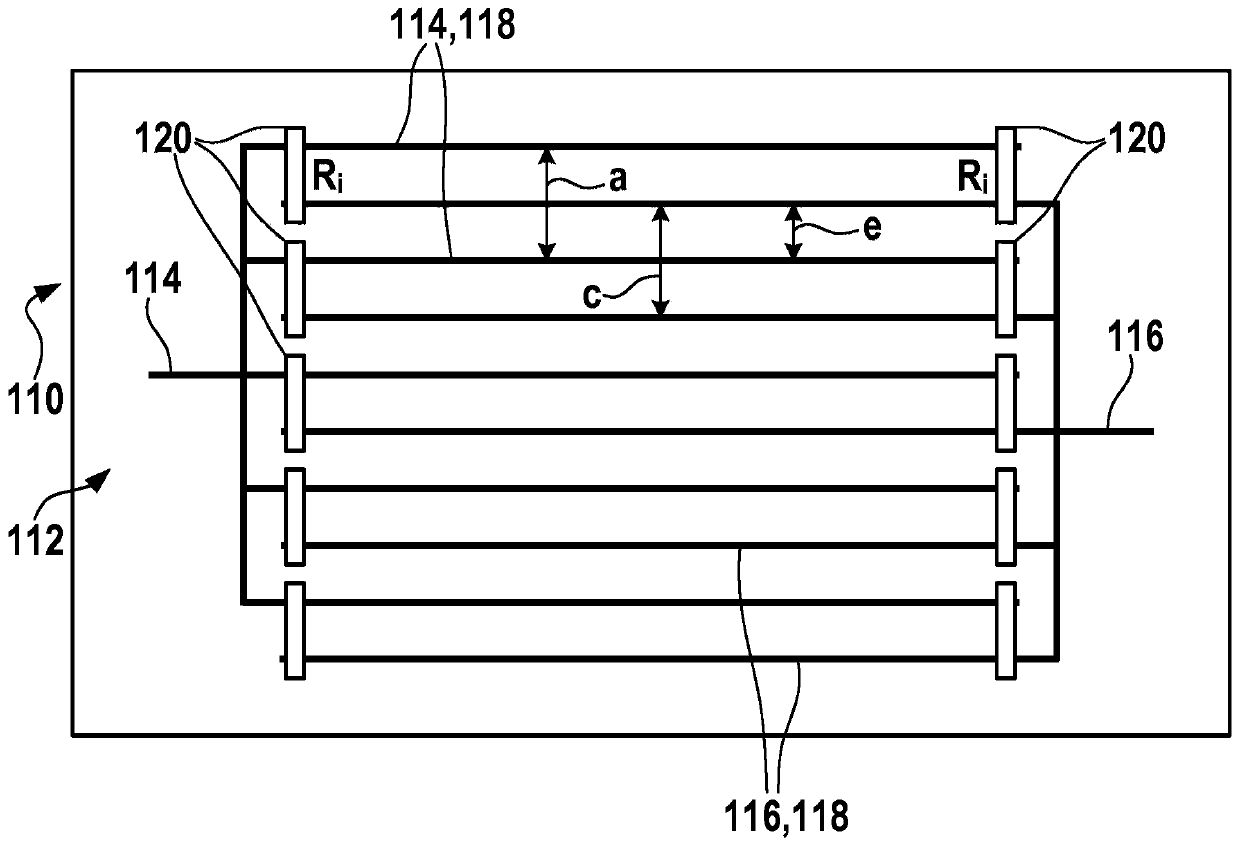

[0045] exist Figures 1 to 3 In FIG. 2 , different embodiments of a sensor element 110 according to the invention are shown in plan view for sensing particles of a measurement gas in a measurement gas chamber. Figure 4 The dependence of the total electrode resistance 128 and the self-diagnostic current 126 on the number of defective electrode fingers 132 is shown in the form of a diagram 130 , wherein the diagram 130 relates to the sensor element 110 according to the invention in the image 3 The implementation shown in . exist Figure 5 and 6 Different embodiments of a sensor element 110 according to the invention for sensing particles of a measurement gas in a measurement gas chamber are shown in . These figures will be set forth together below.

[0046] The sensor element 110 can in particular be provided for use in a motor vehicle. In particular, the measurement gas can be the exhaust gas of a motor vehicle. The sensor element 110 can in particular comprise one or mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com