Power electronics unit having separating element decoupling high-voltage side from low-voltage side

A technology for power electronic devices and components, used in electrical components, magnetic/electric field shielding, printed circuit board sockets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

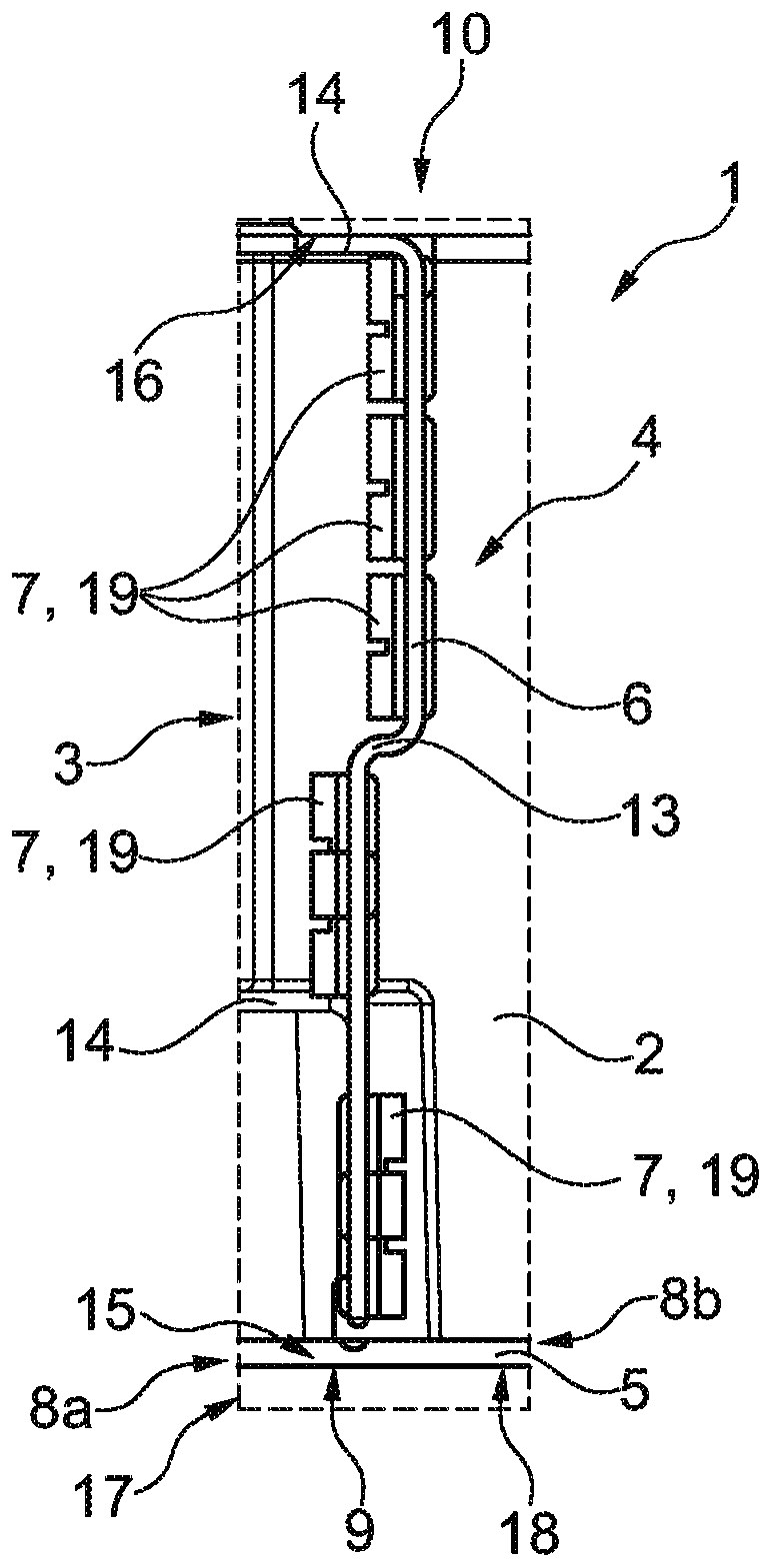

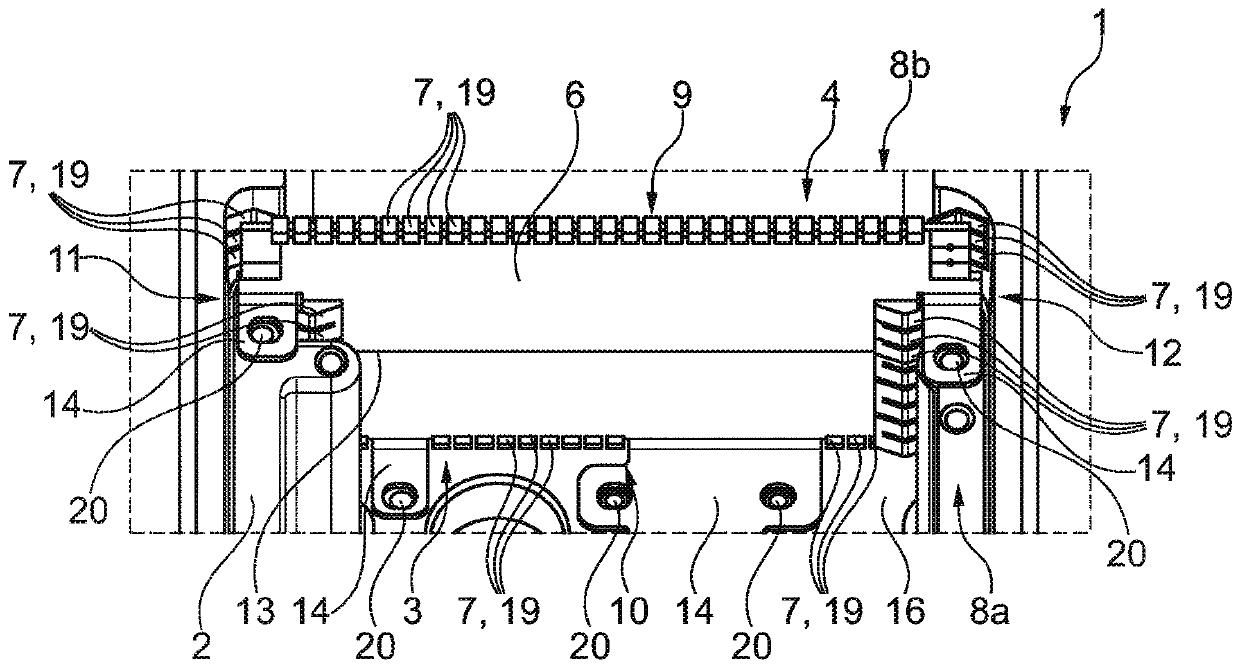

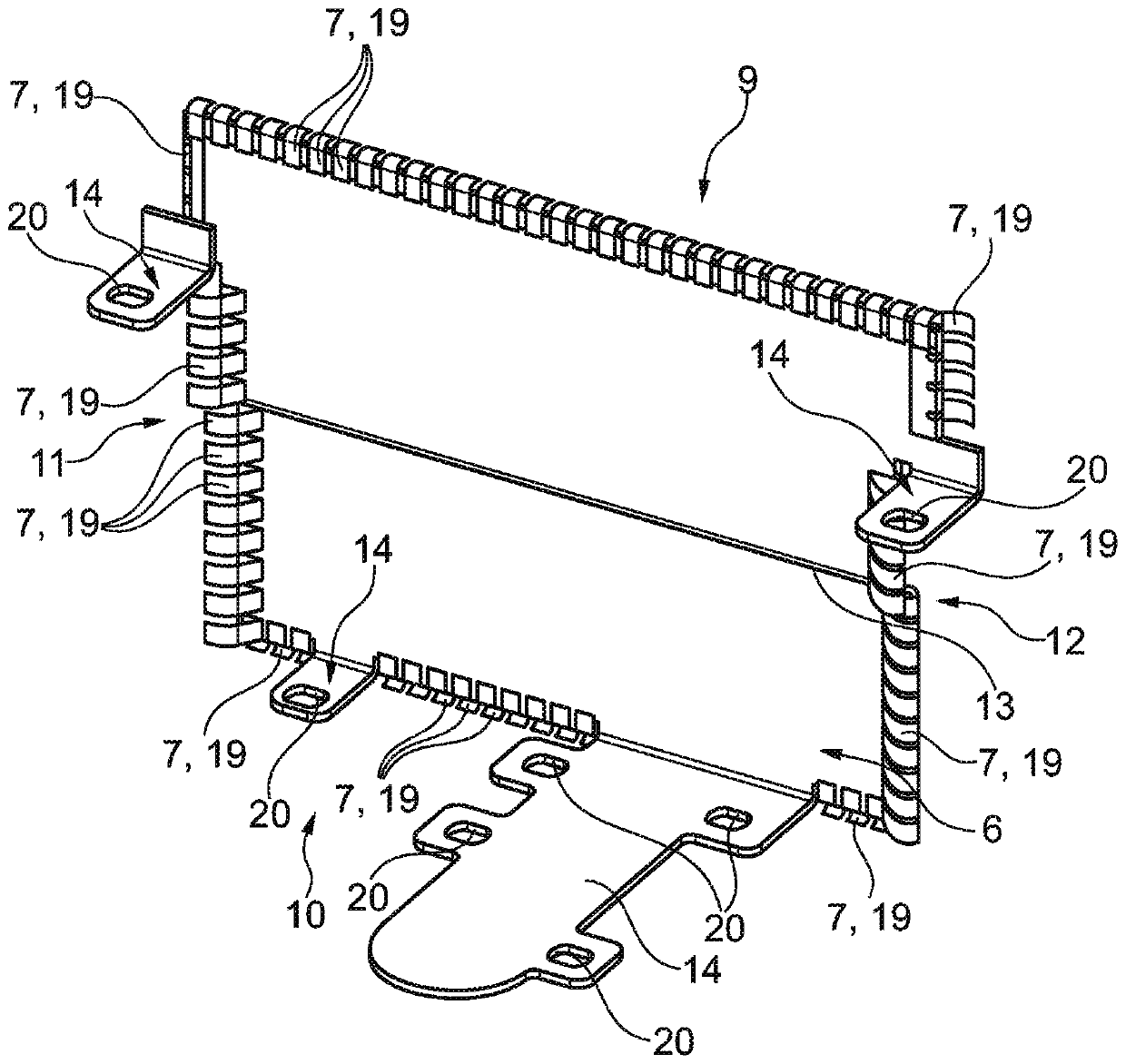

[0028] exist figure 1 The power electronics unit 1 according to a preferred exemplary embodiment can be seen in the figure under the principle structure of the power electronics unit. During operation, the power electronics unit 1 is preferably installed in a hybrid system of a hybrid drive train of a motor vehicle, which is designed as a hybrid module. The power electronics unit 1 is preferably a component of an electric drive of a hybrid system, which also has an electric motor. The power electronics unit 1 is used to supply electrical energy to the electric motor of the hybrid module or to extract electrical energy from the electric motor.

[0029] The power electronics unit 1 has a housing 2 , in which, in turn, the power electronics, which are not fully shown here for the sake of clarity, are arranged. The housing 2 basically accommodates a plurality of electronic components that are assembled into a power electronics unit. exist figure 1 The circuit board 5 of this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com