A high-efficiency spraying and drying device for automobile wheel hub spraying

A drying device and a technology for automobile wheels, which are applied in the field of auto parts, can solve the problems that the wheels cannot be painted, and the wheels cannot be painted with different colors, so as to achieve a good environment, reduce work intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

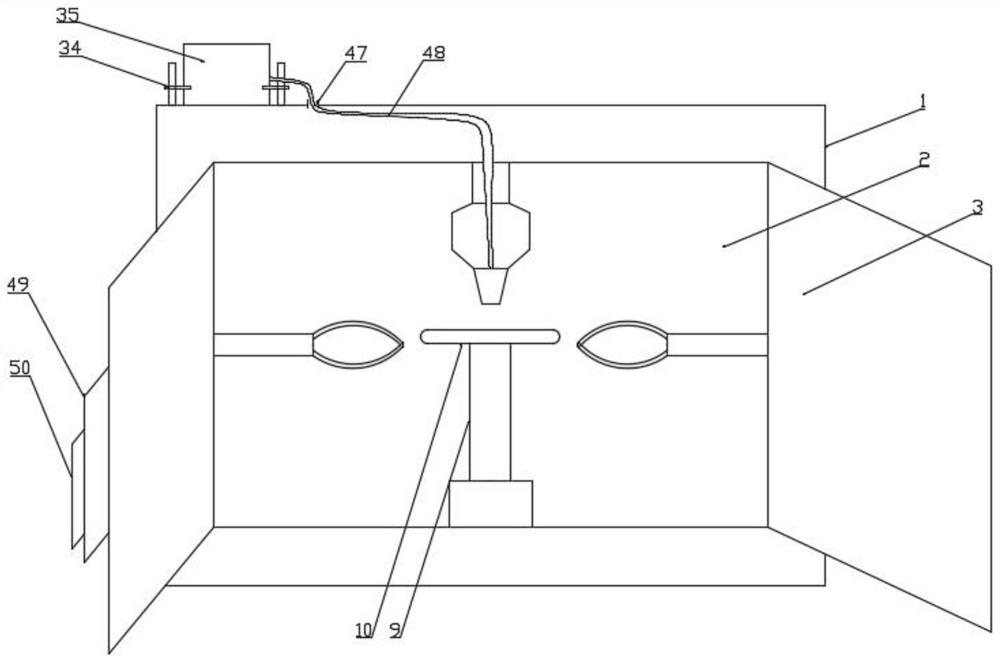

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, in this implementation:

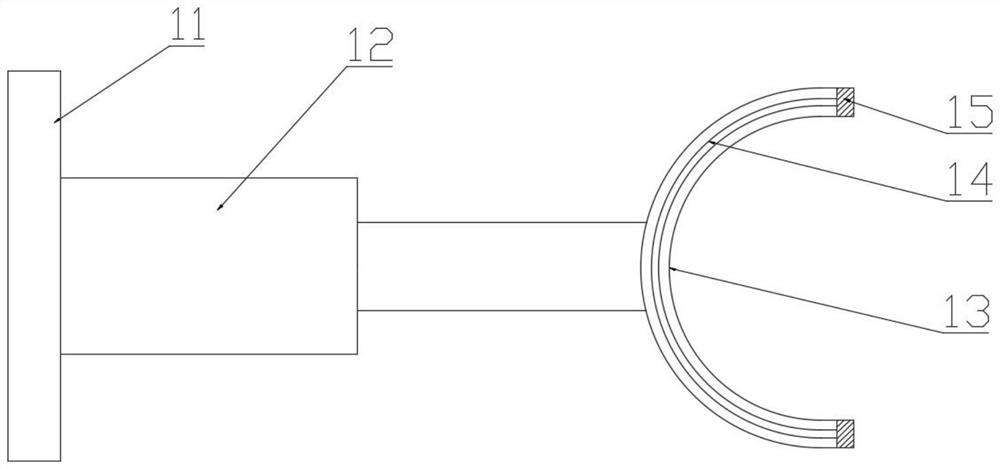

[0025] In this device, the model of the controller 50 is a PLC controller of s7-200, and the signal sending end of the controller 50 is respectively connected with the ventilating fan 8, the liftable adjustment rod 9, the horizontally telescopic fixed rod 12, the energized electromagnet 15, the rotating The signal receiving ends of motor two 20, painting solenoid valve 23, motor 27, electric heating element 33, air pump 39, three-way solenoid valve 41 carry out control connection.

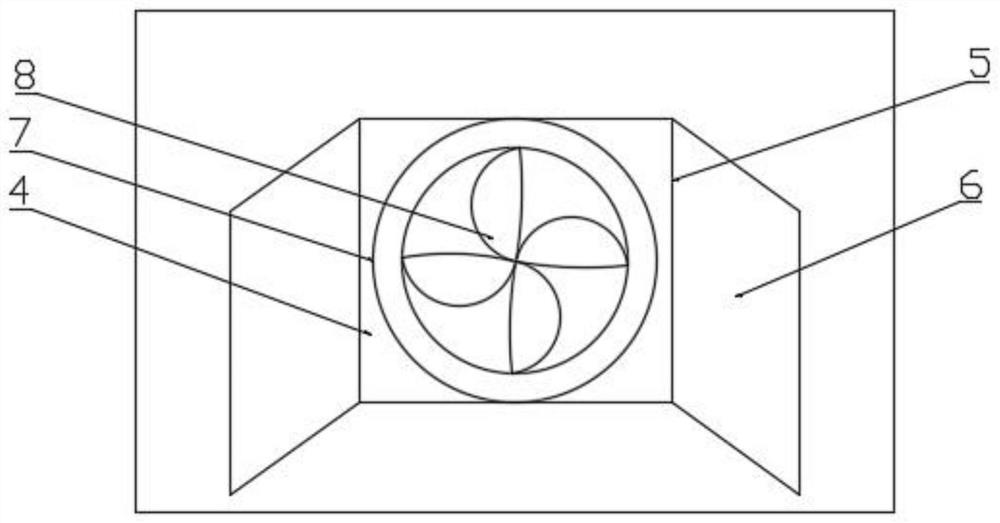

[0026] The invention point of the application lies in the structural design of the rotary inkjet drying device, combined with the attached Figure 4 And attached Figure 5 , the rotary inkjet drying device comprises a spiral track 16, the spiral track 16 is fixedly installed in the middle part of the innermost top of the drying box 1, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com