General assembled edge covering production line for car roof and production method

A general-purpose technology for automobile roofs, applied in the directions of forming tools, feeding devices, positioning devices, etc., can solve the problems of labor-intensive, labor-intensive, heavy equipment weight, etc., achieve fast action, reduce operators, and improve production. beat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

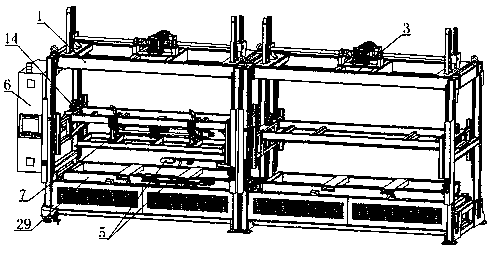

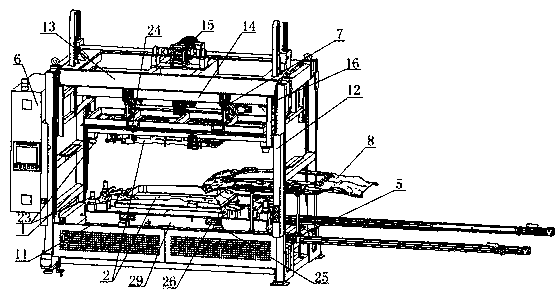

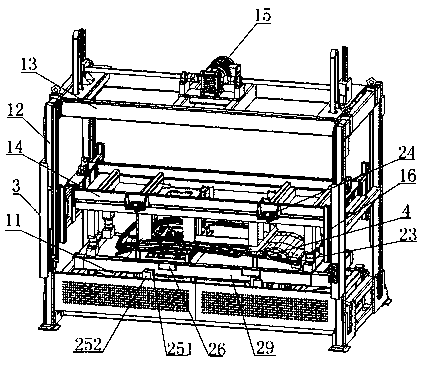

[0035] Refer to attached figure 1 , a general-purpose assembly and wrapping line for car roofs, which includes a complete machine frame, an assembly module 2, a wrapping module 4, a handling mechanism 5, and a control box 6. The frame of the complete machine is designed to have at least two stations. They are the first wire body frame 1 and the second wire body frame 3 respectively. The assembly module 2 is designed and installed in the first wire body frame 1, and the hemming module 4 is designed and installed in the second wire body frame 3. The first wire body frame The right side of 1 and the left side of the second wire body frame 3 are fixedly connected together, and the transport mechanism 5 is installed on the stations of the first wire body frame 1 and the second wire body frame 3; the control box 6 is installed on the wire body frame of the whole machine On one side, the control box 6 is connected to the first wire body frame 1, the second wire body frame 3, the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com