Processing method for silicon bronze solid retainer for short cylindrical roller bearing without outer ring rib

A solid cage and short cylindrical roller technology, which is applied in the field of silicon bronze solid cage processing of short cylindrical roller bearings with no ribs on the outer ring, can solve the problems of difficult control of surface defects, internal defects of the cage, and low assembly matching rate, etc. problems, to ensure the quality of product processing and improve the effect of product integration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

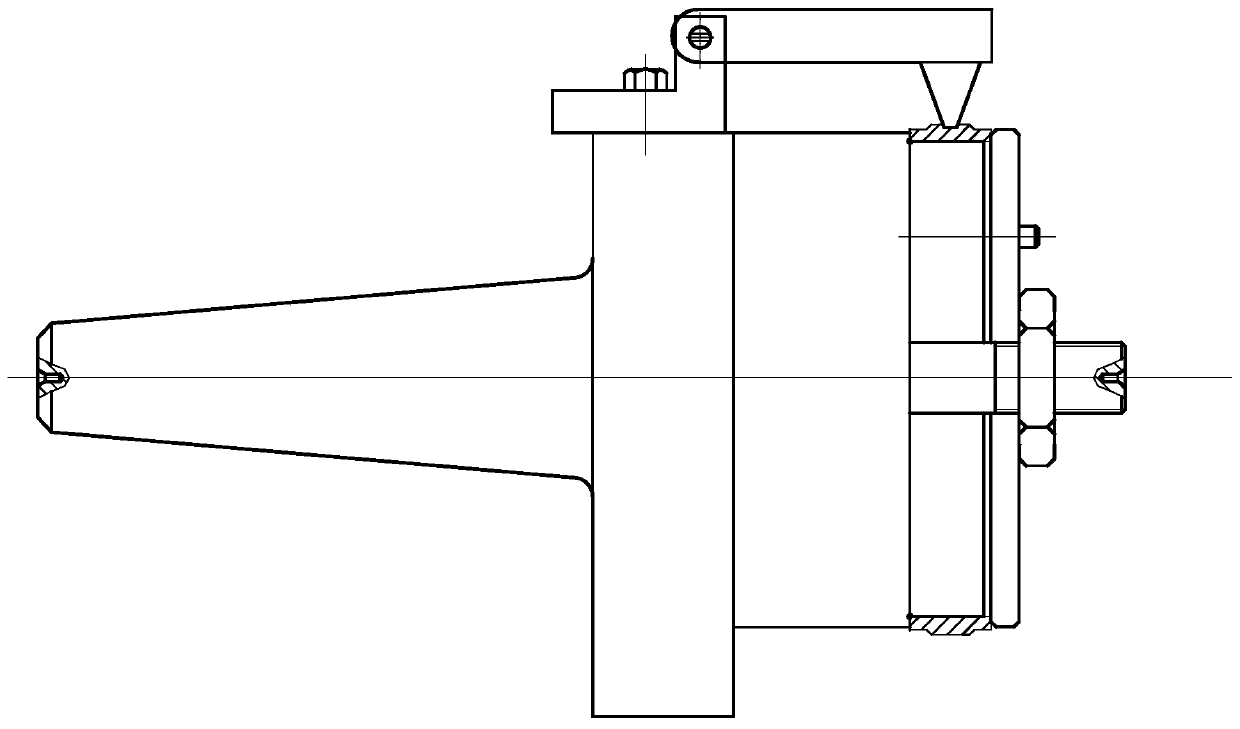

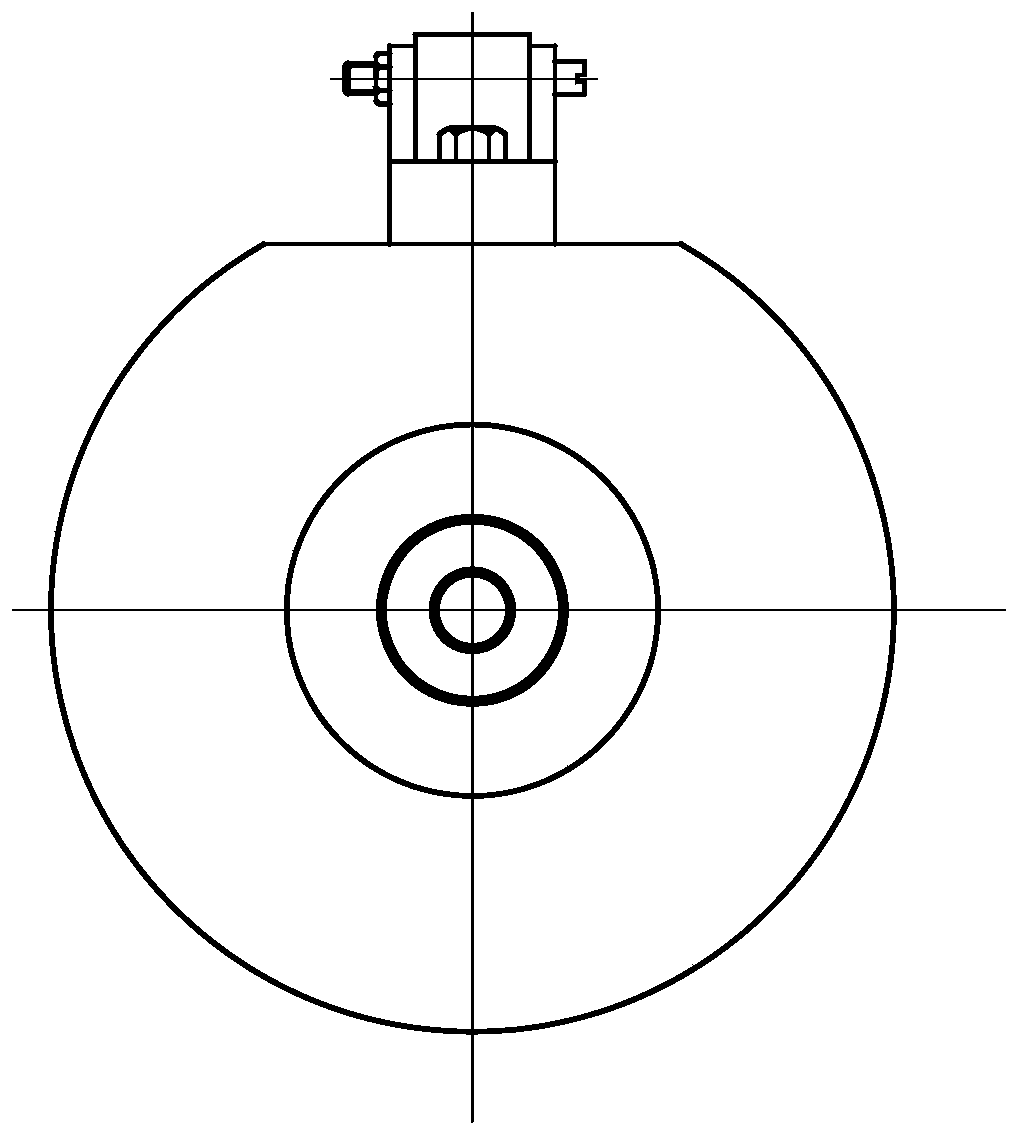

[0067] Specific implementation mode one: as Figure 1~2 and Figure 5 As shown, the processing method of the silicon bronze solid cage of the short cylindrical roller bearing without ribs on the outer ring of this embodiment is realized according to the following steps:

[0068] Step 1. Preliminary cutting of pipe material;

[0069]After cutting, the length of each section of pipe material is the sum of the thickness of 3-5 solid cages;

[0070] Step 2. After the pipe material is cut off, the two end faces and outer diameter of the fine car solid cage:

[0071] Install the cut pipe material on the CNC lathe, the two end faces and the outer diameter of the cut pipe material in the fine turning step 1, the roughness of the end face and the outer diameter of the pipe material is Ra<1.6 μm;

[0072] Step three, water immersion ultrasound:

[0073] Taking the outer diameter of the thin car tube material in step 2 as the incident detection surface, the internal defect detection ...

specific Embodiment approach 2

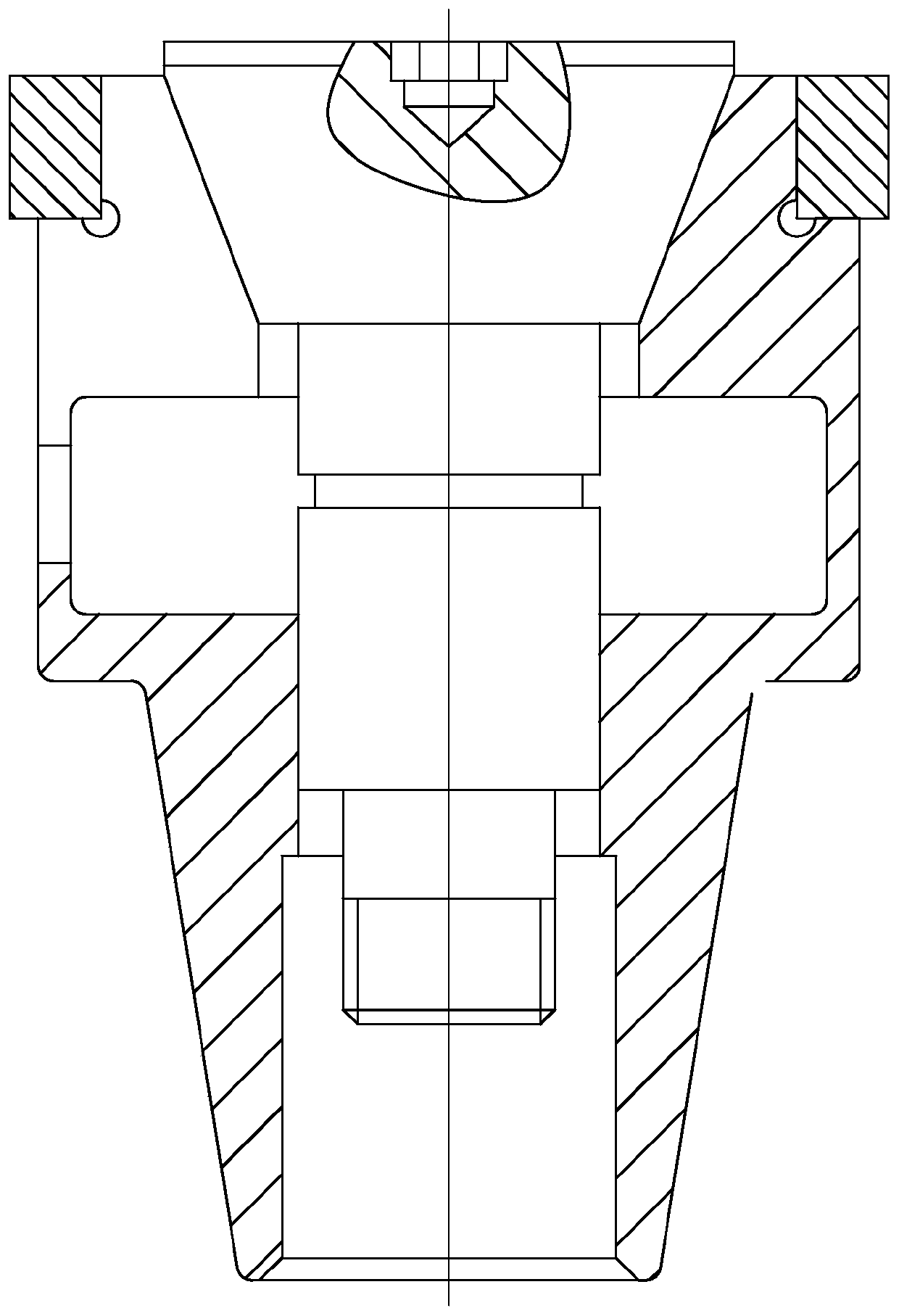

[0114] Specific implementation mode two: as Figure 4 As shown, in the sixteenth step of this embodiment, a dynamic balance mold is used for the primary dynamic balance, and the solid cage is set on the inner diameter jammed tire of the dynamic balance mold. In this way, the dynamic balance mold is an integral structure, and the accumulated error is small, thereby ensuring the overall precision of the mold; the positioning method of the inner diameter of the cage is adopted, because the inner diameter of the cage is the guiding surface, and the machining accuracy is relatively high. Balance the size of the positioning surface of the mold with lathe processing to ensure its proper clearance. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0115] Specific implementation mode three: as figure 2 As shown, the secondary dynamic balance in step 19 of this embodiment adopts a dynamic balance mold, and the solid cage is set on the inner diameter jammed tire of the dynamic balance mold. In this way, the dynamic balance mold is an integral structure, and the cumulative error is small, thereby ensuring the overall precision of the mold; using the inner diameter positioning method of the cage, because the inner diameter of the cage is the guiding surface, the machining accuracy is relatively high, and the obtained dynamic balance data is true. Accurate, improve the processing level of the overall cage. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com