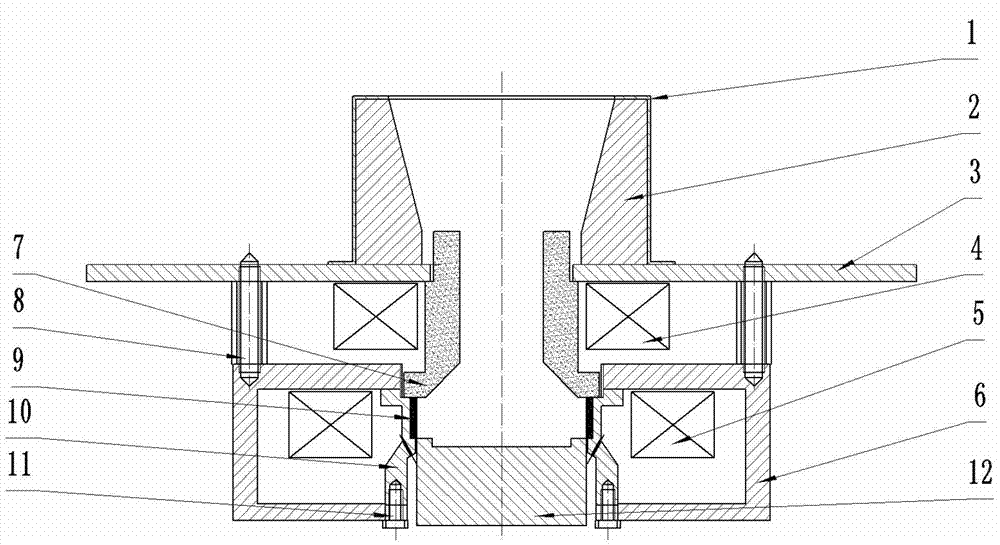

A device and method for producing fine-grained aluminum alloy round ingots

A production method and technology of aluminum alloy, applied in the field of aluminum alloy casting, can solve the problems of restricting the refining effect of ingots and the inability of ultra-high-purity aluminum ingots to achieve refining, so as to reduce the amount of car skin, control internal defects, The effect of refining the coagulated tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The production process steps of the fine-grained aluminum alloy round ingot using the above-mentioned device are as follows:

[0028] (1) Lift the dummy head into the graphite ring before casting, feed the upper coil and the crystallizer with cooling water, the cooling water enters the inner sleeve of the mold through the crystallizer water tank, and is sprayed out from the water hole at the lower part of the inner sleeve of the crystallizer , acting on the surface of the ingot;

[0029] (2) The inner diameter of the inner sleeve of the mold is 198mm. The aluminum melt flows into the mold through the flow channel and the guide tube, and the melt solidifies in the mold for 7 seconds. After the graphite ring forms a slab shell, start the casting machine to start casting: start The casting speed of the car is 70mm / min, and then increases linearly to 100 mm / min within 2min;

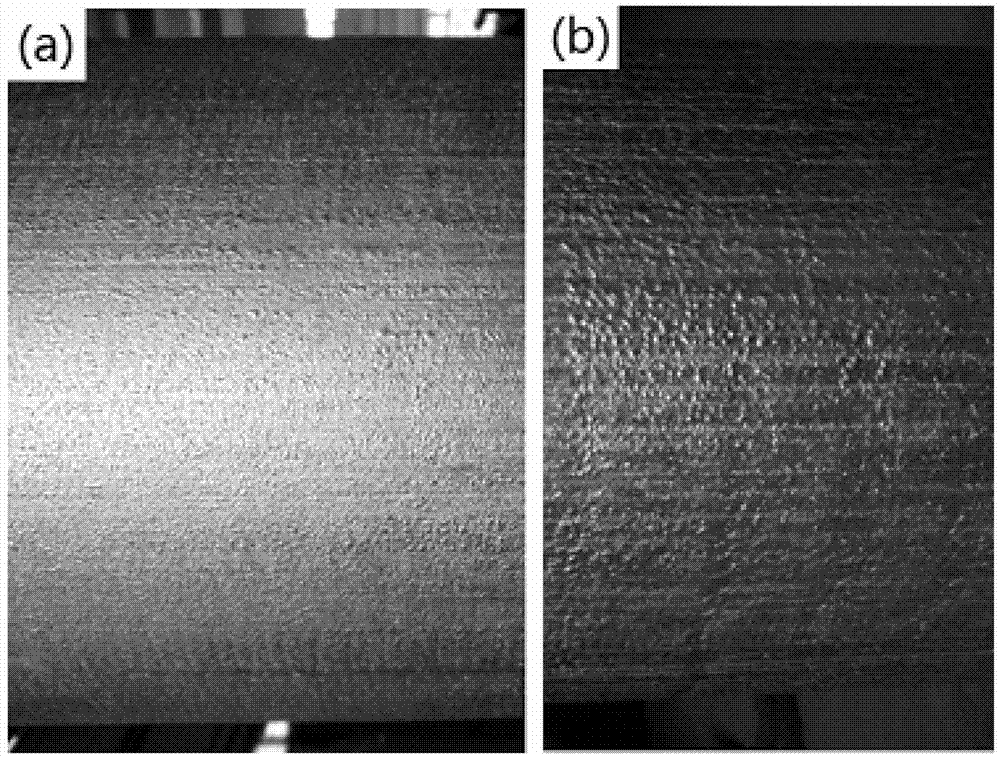

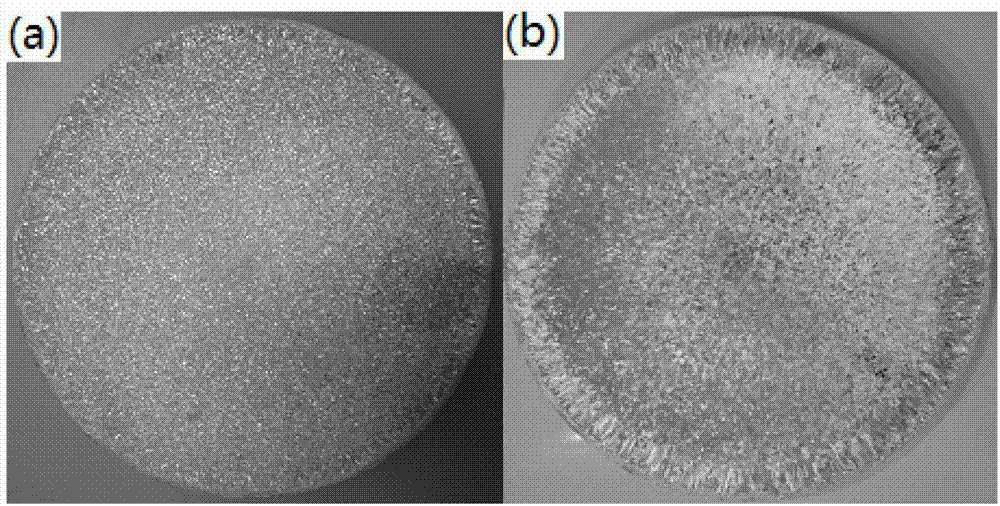

[0030] (3) When the length of the ingot reaches 150mm, turn on the excitation power supply, the fr...

Embodiment 2

[0034] The production process steps of the fine-grained aluminum alloy round ingot using the above-mentioned device are as follows:

[0035](1) Lift the dummy head into the graphite ring before casting, feed the upper coil and the crystallizer with cooling water, the cooling water enters the inner sleeve of the mold through the crystallizer water tank, and is sprayed out from the water hole at the lower part of the inner sleeve of the crystallizer , acting on the surface of the ingot;

[0036] (2) The inner diameter of the inner sleeve of the mold is 50 mm. The aluminum melt flows into the mold through the flow channel and the guide tube. The melt solidifies in the mold for 5 seconds. After the graphite ring forms a billet shell, start the casting machine to start casting: start The casting speed of the car is 100mm / min, and then increases linearly to 260 mm / min within 2min;

[0037] (3) Turn on the excitation power supply when the ingot length reaches 150mm, the current freq...

Embodiment 3

[0041] The production process steps of the fine-grained aluminum alloy round ingot using the above-mentioned device are as follows:

[0042] (1) Lift the dummy head into the graphite ring before casting, feed the upper coil and the crystallizer with cooling water, the cooling water enters the inner sleeve of the mold through the crystallizer water tank, and is sprayed out from the water hole at the lower part of the inner sleeve of the crystallizer , acting on the surface of the ingot;

[0043] (2) The inner diameter of the inner sleeve of the mold is 310mm. The aluminum melt flows into the mold through the flow channel and the guide tube, and the melt solidifies in the mold for 5 seconds. After the graphite ring forms a billet shell, start the casting machine to start casting: start The turning speed is 40mm / min, and then increases linearly to 60mm / min within 2min;

[0044] (3) Turn on the excitation power supply when the length of the ingot reaches 150mm, the frequency rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com