Small-sized device for simulating fresh mixed concrete dynamic process

A dynamic process and small-scale device technology, which is applied in the direction of clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of concrete work performance decline, difficulty increase, slump loss, etc., to improve convenience and Accuracy, control of stirring speed, and the effect of adjusting the stirring angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

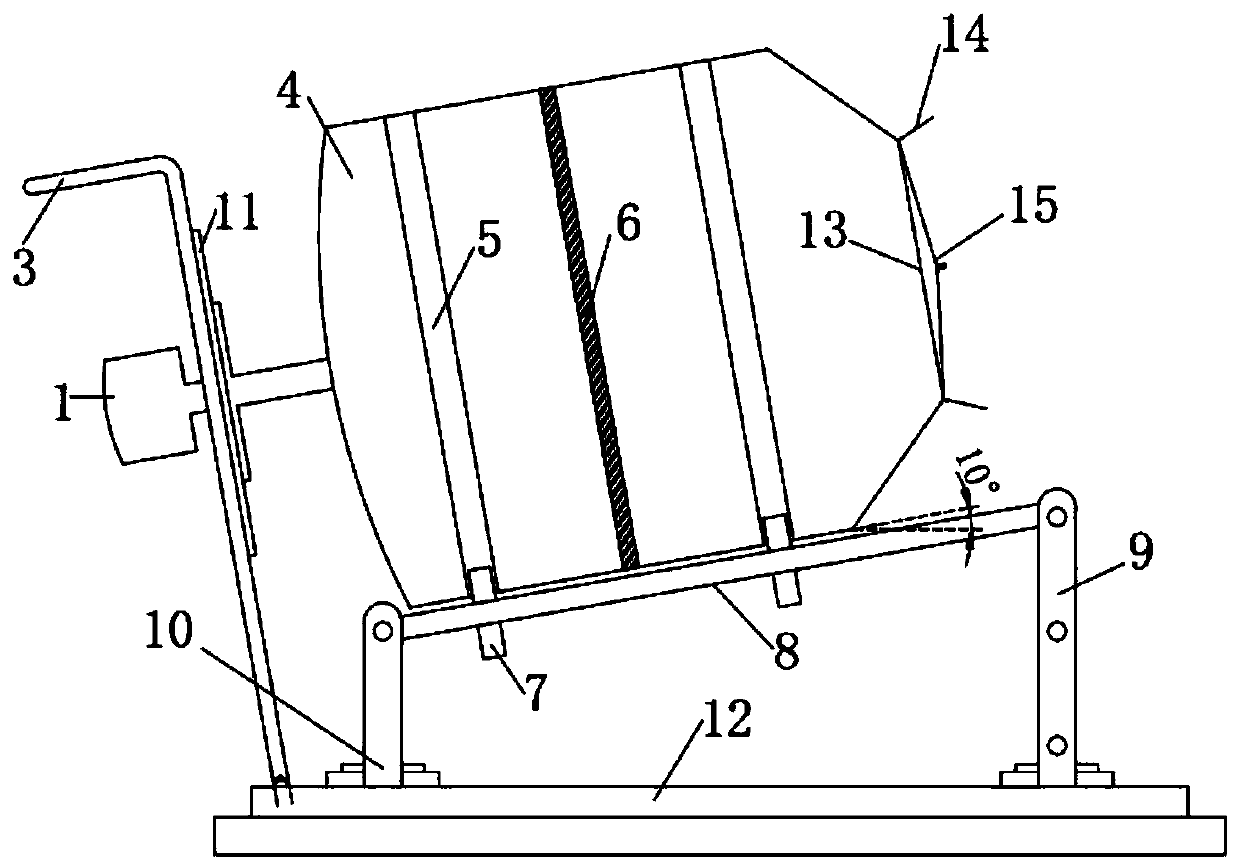

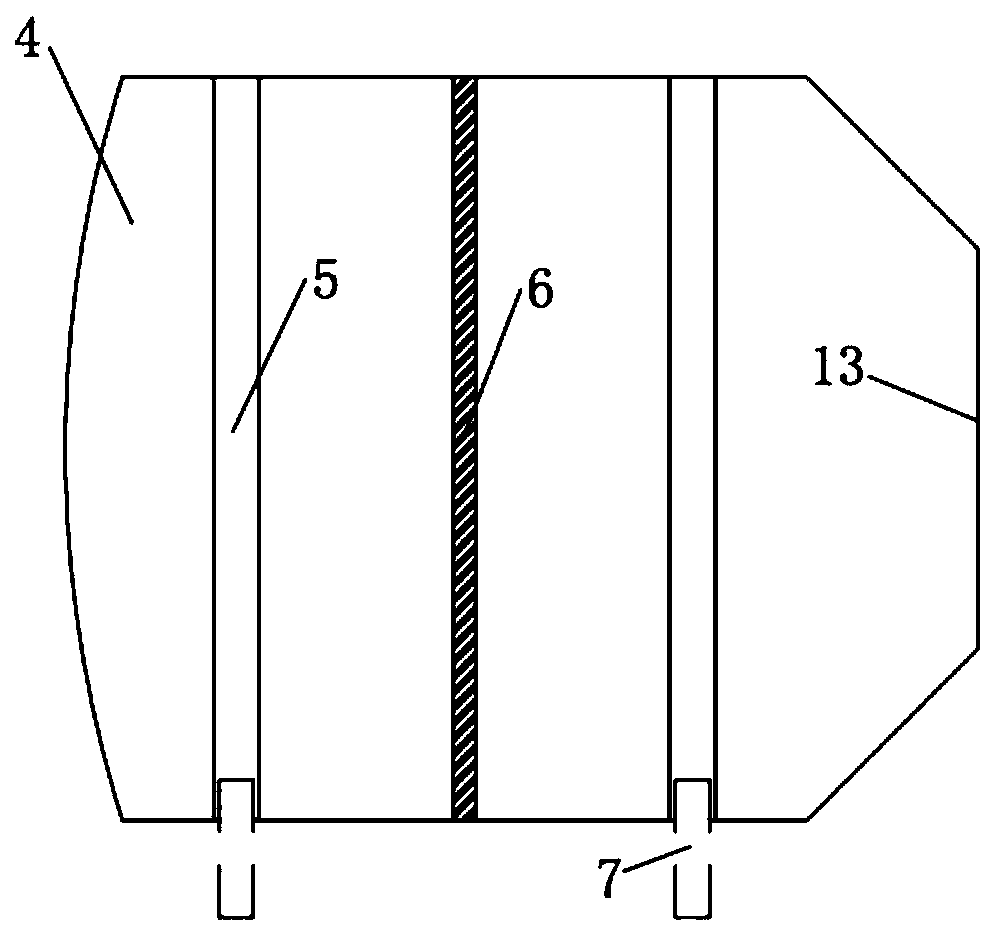

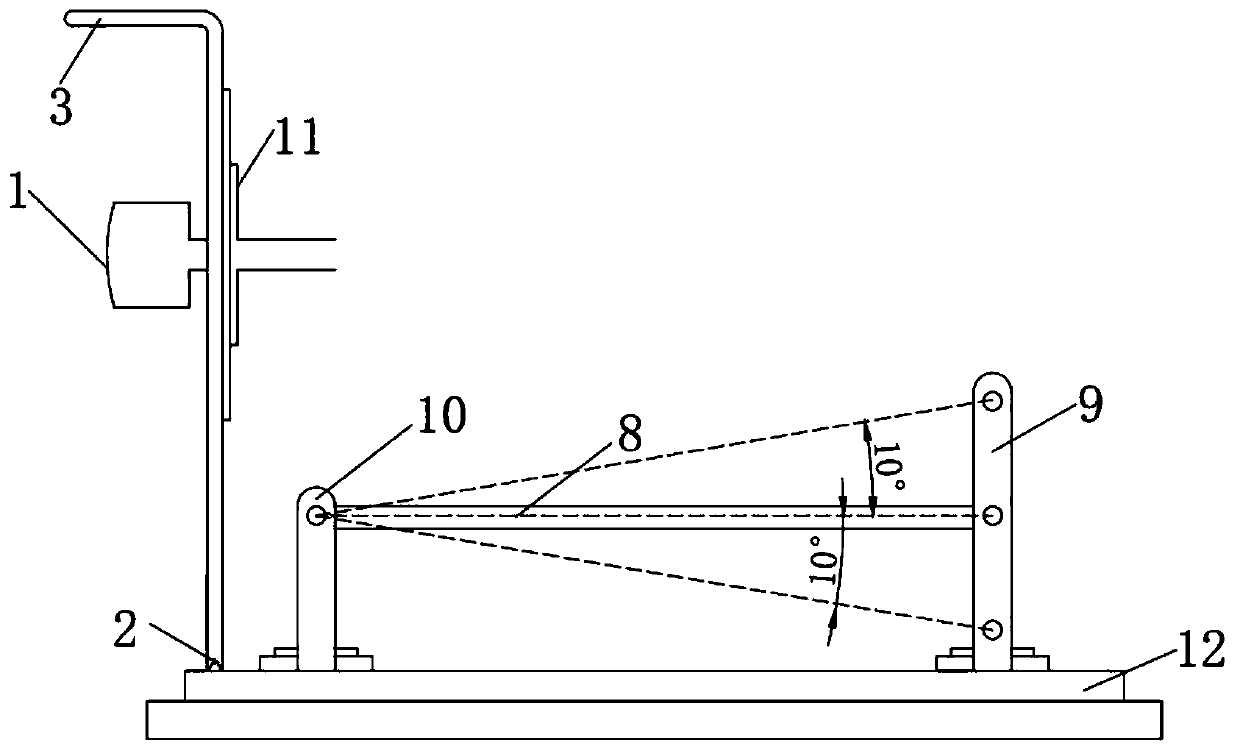

[0019] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-7 Shown: the present invention provides a kind of small-sized device for simulating the dynamic process of freshly mixed concrete, comprising steel backing plate 12, two sets of mixing drum support structures, movable handrail 3 and mixing drum 4, two sets of mixing drum support structures are respectively arranged on steel The front and back sides of the backing plate. The supporting structure of the mixing drum comprises a small bracket 10 on the left side, a small bracket 9 on the right side and a steel pipe 8, and a plurality of beams are arranged side by side along the height direction on the small bracket on the right side, and the left end of the steel pipe and the small bracket on the left side Hinged, the right end is articulated with one of the beams through a hook, and two tugs 7 are fixedly set on the steel pipe. The movable armrest is arranged on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com