Vertical dual-layer heating stirrer

A double-layer heating and mixer technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., to achieve the effects of controlling the stirring speed, saving space, and saving length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

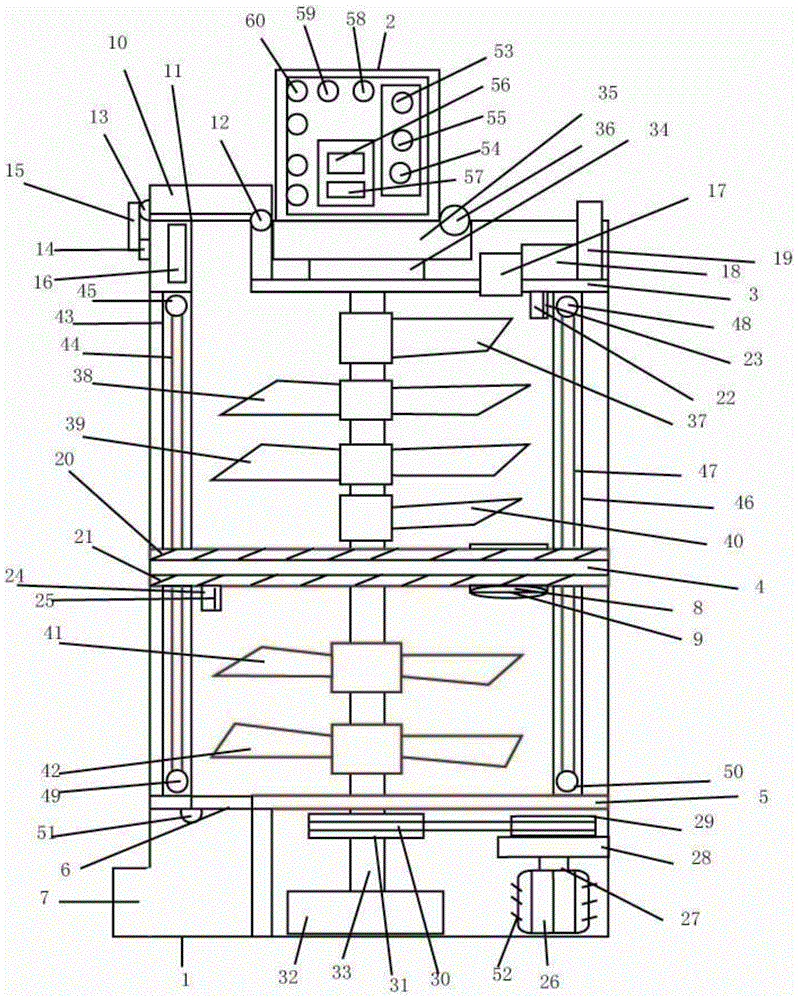

[0018]This embodiment includes a casing 1, a controller 2, a baffle A3, a baffle B4, a baffle C5, a sealing plate 6, a discharge port 7, a discharge port 8, a hinge A9, a sealing cover 10, a gasket 11, Hinge B12, seal lock A13, seal lock B14, hand buckle 15, monitor 16, air filter 17, fan 18, air duct 19, heat shield A20, heat shield B21, camera A22, thermometer A23, camera B24 , thermometer B25, motor 26, rotating shaft 27, reduction box 28, motor wheel 29, chain 30, sprocket 31, base 32, main shaft 33, stabilizer 34, bearing with seat 35, handwheel 36, paddle A37, paddle Sheet B38, paddle C39, paddle D40, paddle E41, paddle F42, heat dissipation layer A43, heat dissipation pipe A44, heater A45, heat dissipation layer B46, heat dissipation pipe B47, heater B48, heater C49, heater D50 , hinge C51, the controller 2 is on the top of the casing 1, and the controller 2 has on-off key A53, on-off key B54, on-off key C55, image display screen 56, temperature display screen 57, camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com