A high-pressure ultra-high pressure shielded electric control valve

An electric regulating valve and ultra-high pressure technology, applied in electric components, lift valves, valve devices, etc., can solve the problems of unreliable sealing, inconvenient installation and maintenance, and inability to eliminate expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

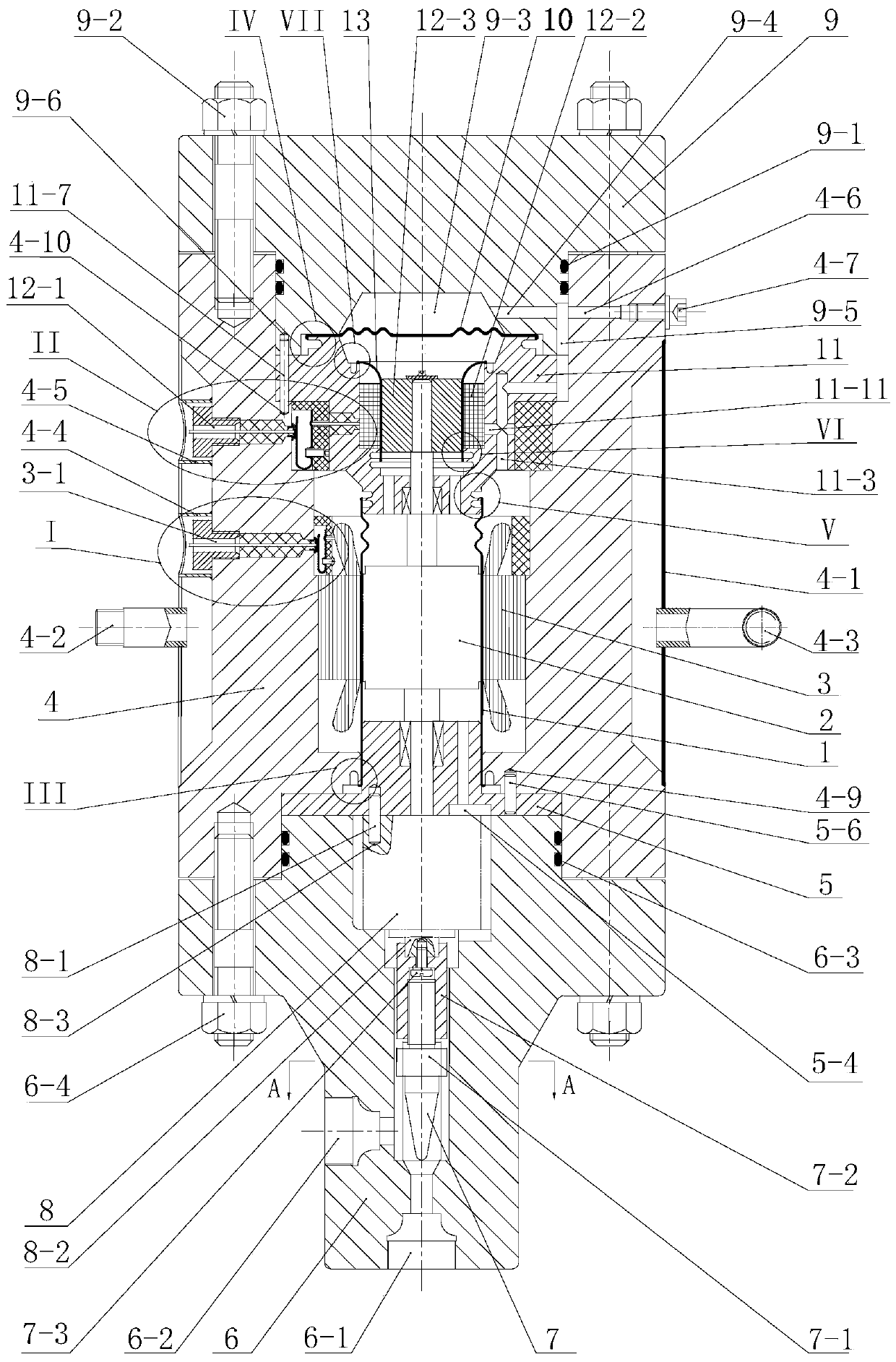

[0051] Such as figure 1 As shown, the technical solution of the present invention is composed of valve body 6, reducer 8, valve core assembly 7, motor housing 4, motor stator 3, motor lead wire assembly 3-1, shielding sleeve 1, motor rotor 2, valve body End bearing assembly 5, rear cover 9, rear cover end resolver and bearing assembly 11, resolver 12, resolver lead wire assembly 12-1, secondary shielding sleeve 13 and pressure balance diaphragm 10 constitute.

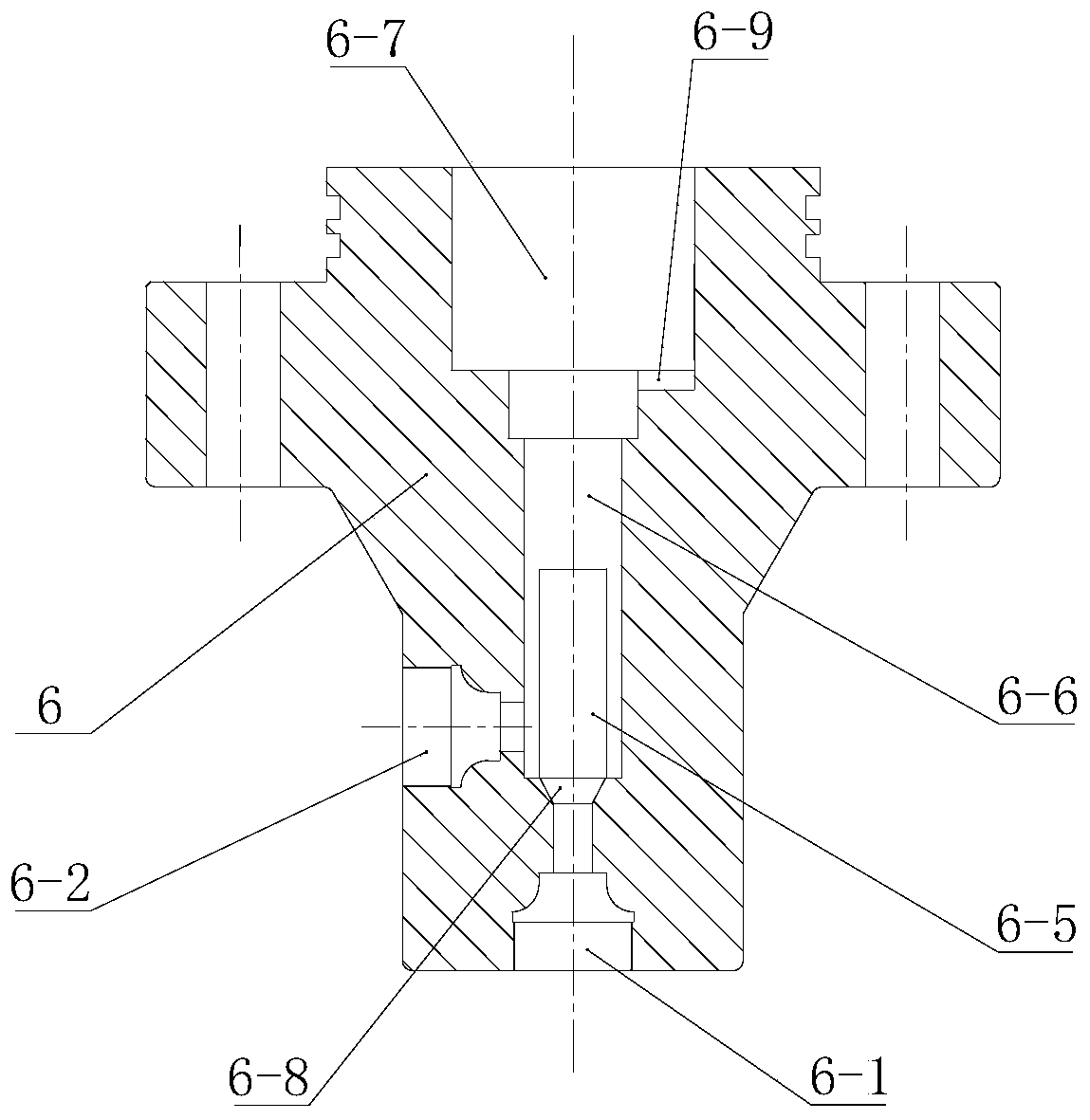

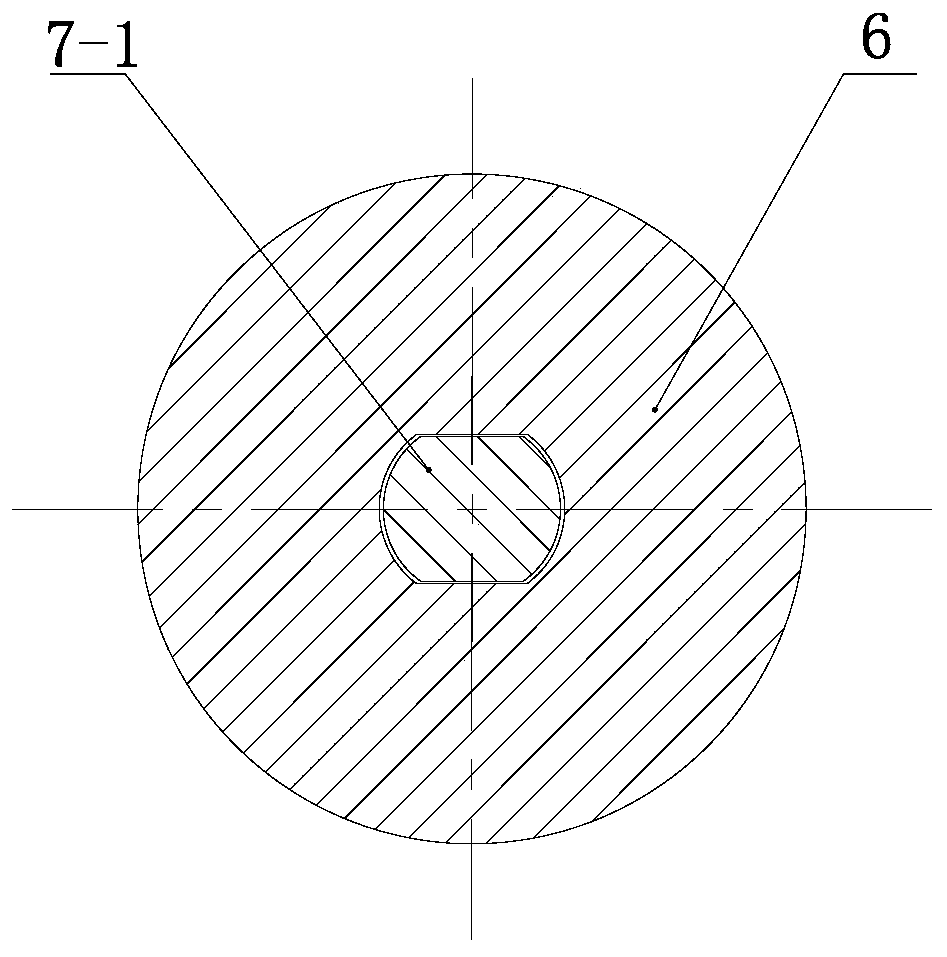

[0052] Such as figure 2 , image 3 As shown, the valve body 6 is a combination composed of a flat cover with a boss, a cylinder, and a coaxial transitional cone between the two. S30408 stainless steel forgings are selected; Hole 6-7, drive sleeve movement hole 6-6, valve core movement chamber 6-5, valve port 6-8 and valve inlet 6-1; from the outer cylindrical surface of the cylinder to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com