Fluid control valve and fluid control valve assembling method

A technology of fluid control valves, assembly methods, applied to parts in contact between valve elements and valve seats, valve operating/releasing devices, valve devices, etc., capable of solving the problems of no representation, no insight into the correlation, etc., Achieve good adaptability, good durability, and suppress the change of Cv value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

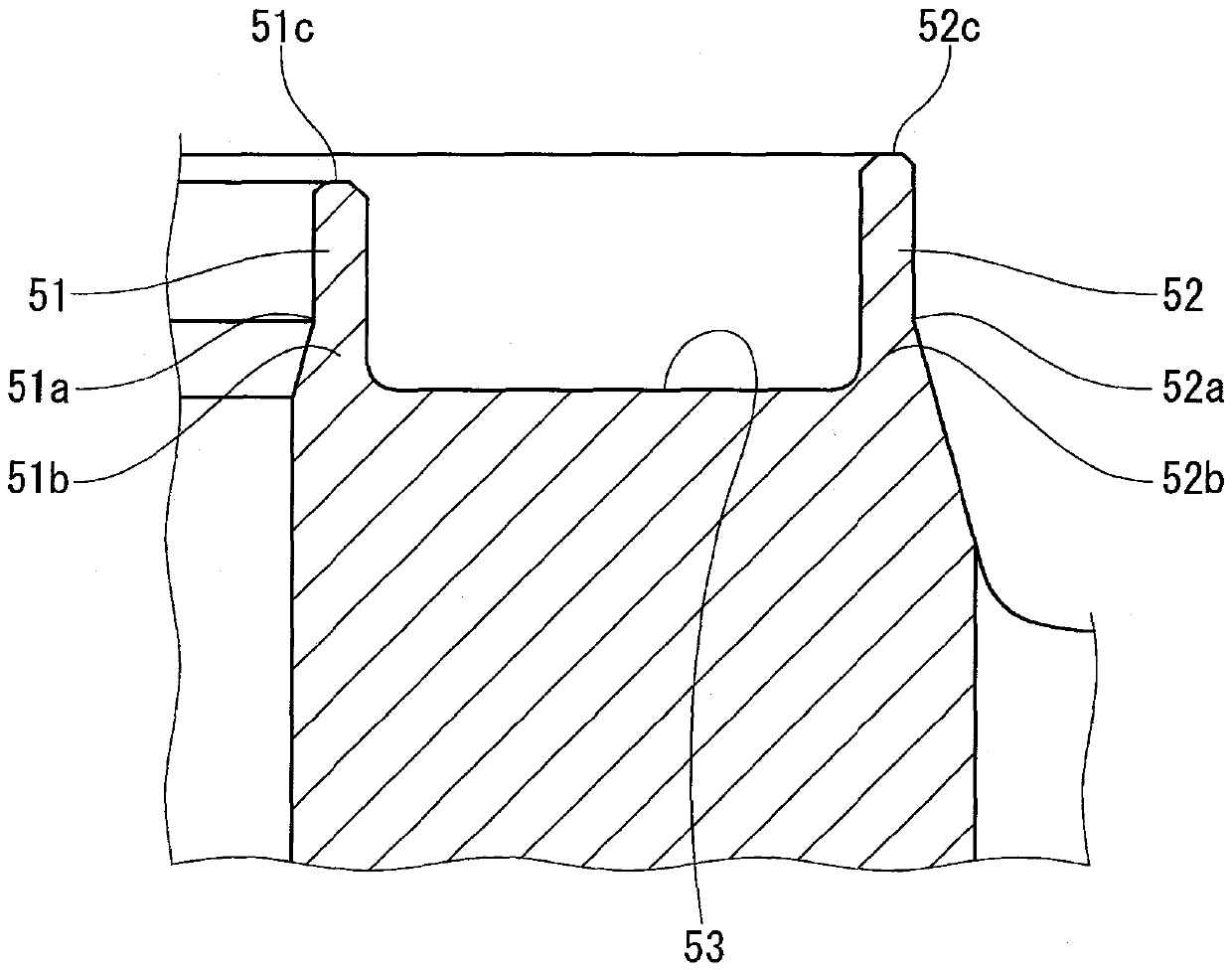

[0050] Hereinafter, an embodiment (this example) of the fluid control valve of the present invention will be described in detail with reference to the drawings. The fluid control valve in this example is a diaphragm valve using a diaphragm, such as figure 1 , figure 2 As shown, it is a valve with an annular valve seat 2 and a diaphragm 1, the annular valve seat 2 is arranged in a valve body 14, 32 having an inlet 4 and an outlet 5, and the diaphragm 1 is opposite to the ring shaped valve seat 2 and abuts / leaves (takes off) under the lifting motion of the rod 12, 40, figure 1 A longitudinal sectional view showing an example of the valve of the present invention, figure 2 It is a longitudinal sectional view showing another example of the valve of the present invention.

[0051] In addition, as will be described later, these valve structures are respectively equipped with actuator bodies 11 and 33, and the rods 12 and 40 in this figure are rods for actuators, but the valve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com