Vehicle reliability test bench and use method thereof

A technology of reliability and test bench, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., and can solve the problems of simulating a single driving state of a car, low promotion, and inability to simulate a state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

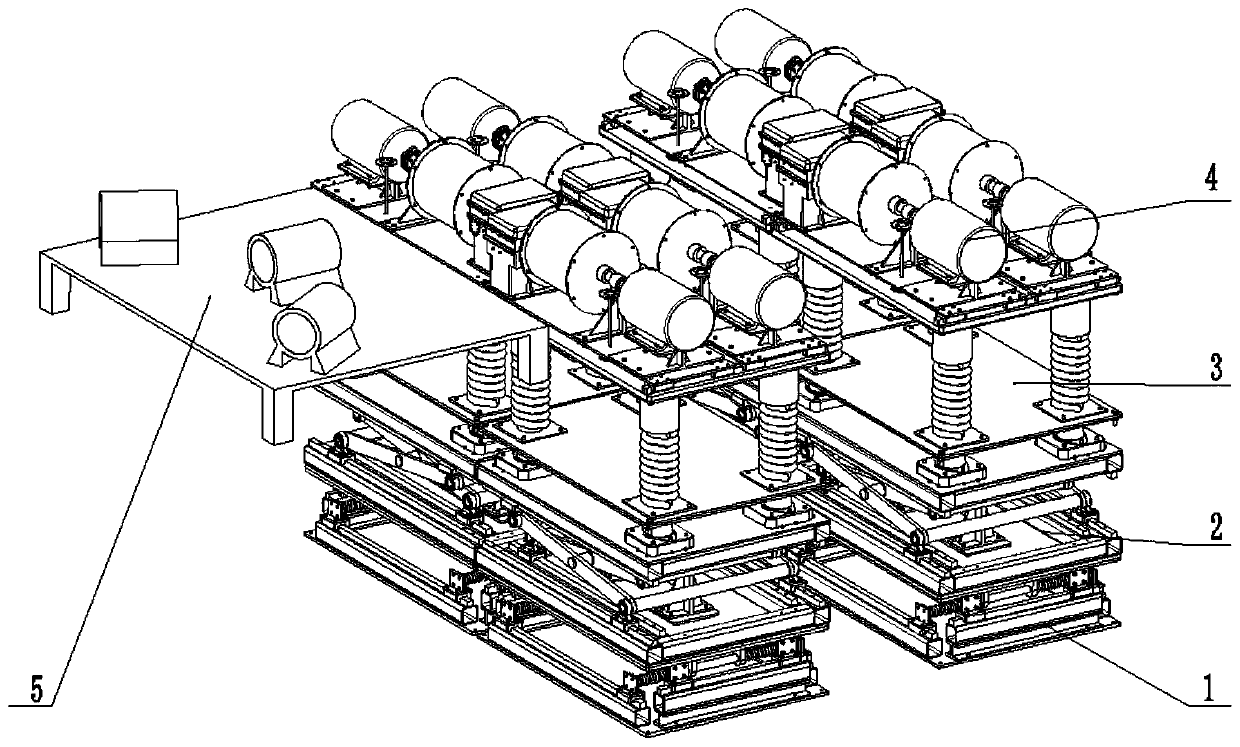

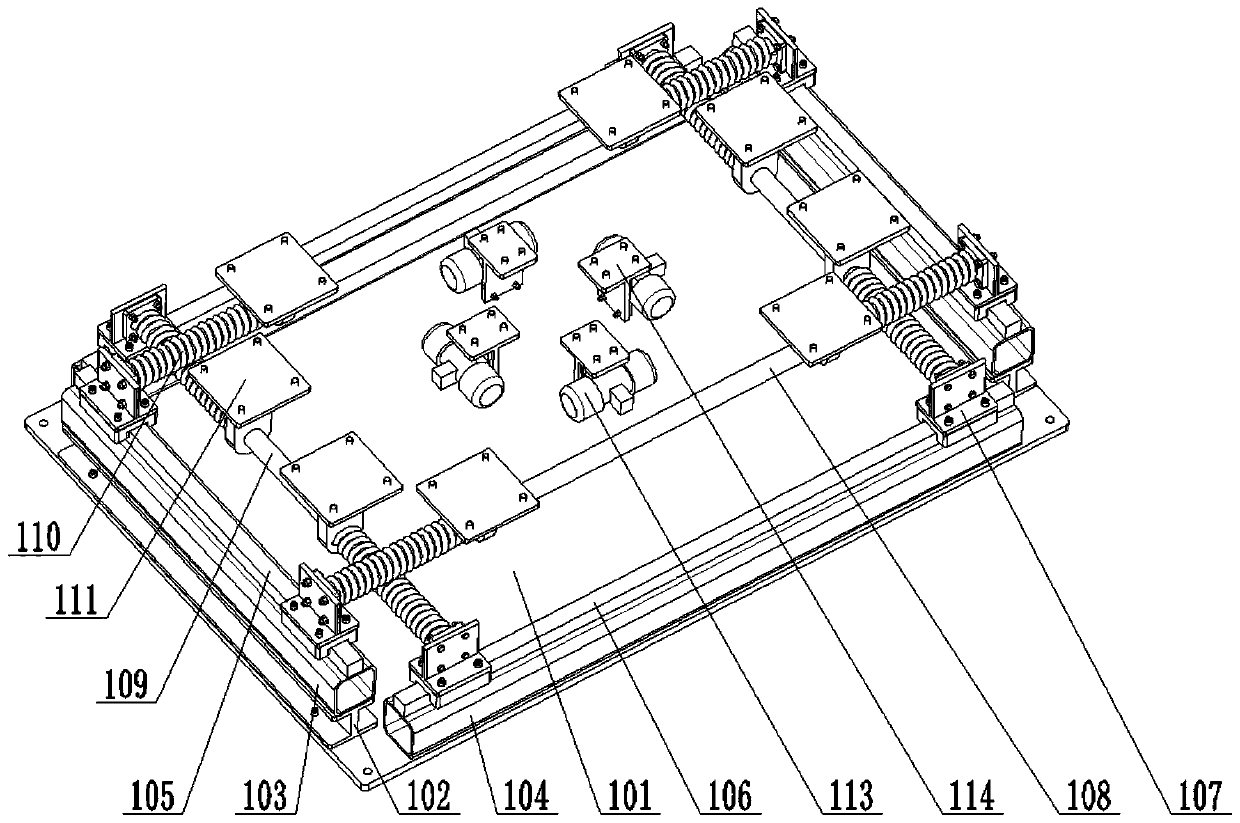

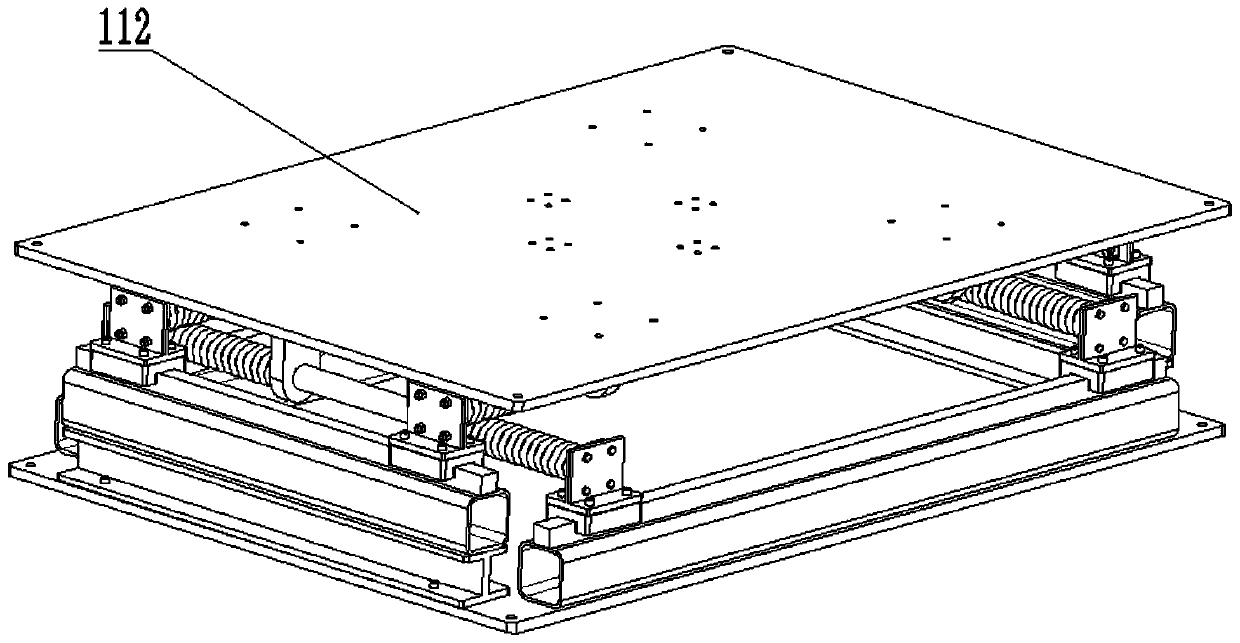

[0044] Such as figure 1 As shown, the vehicle reliability test bench includes four X-Y axis excitation assemblies 1, four Z axis excitation assemblies 3, four lifting and rotating assemblies 2, four drum assemblies 4 and a fan assembly 5. Every two X-Y axis excitation components 1 are installed through wide-side docking, and the top of each X-Y axis vibration component 1 is installed with a lifting and rotating component 2, and the top of each lifting and rotating component 2 is equipped with a Z-axis vibration component 3 , a drum assembly 4 is installed on the top of each Z-axis excitation assembly 3, and the X-Y axis excitation assembly 1, Z-axis excitation assembly 3, lifting rotation assembly 2 and drum assembly 4 constitute the overall main assembly, and the adjacent whole There is a gap between the main components, and the gap can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com