A Speed Planning Method for Acceleration and Deceleration of CNC Machine Tool under Constant Force Constraint

A technology of speed planning and constraint conditions, applied in the direction of digital control, electrical program control, etc., can solve the problems that the performance of the servo motor system cannot be maximized, the servo motor system cannot be effectively guaranteed, and the speed planning method is not safe, etc., to achieve increased stability performance, improve processing efficiency, and reduce the effect of following error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

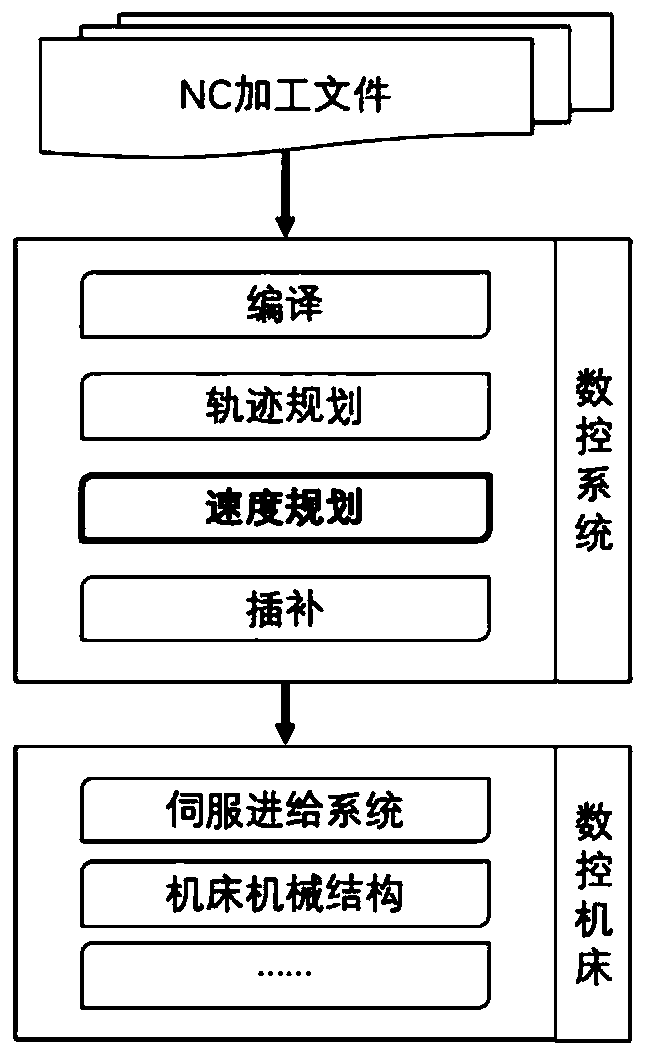

[0036] Below in conjunction with accompanying drawing and embodiment technical scheme of the present invention is described in detail as follows:

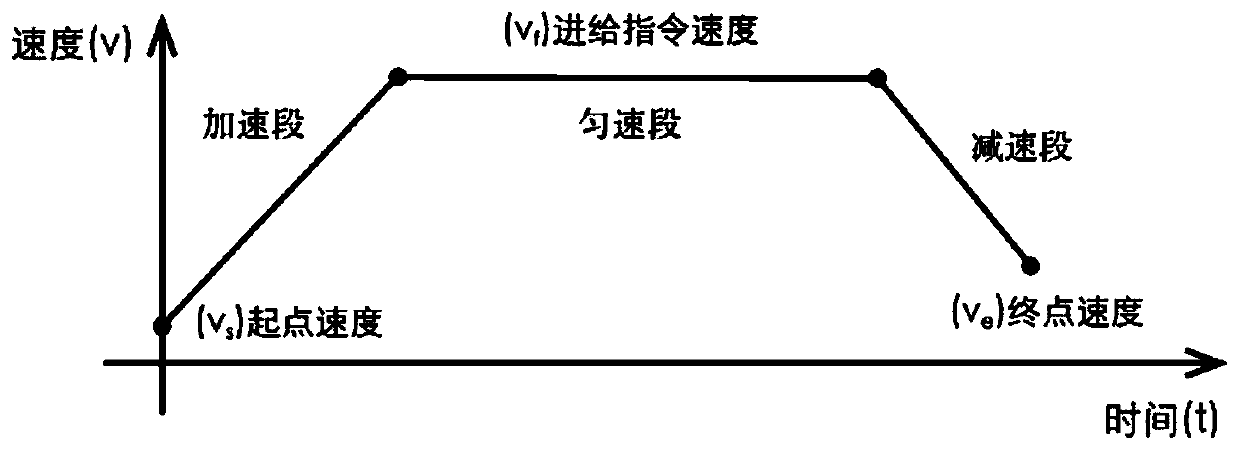

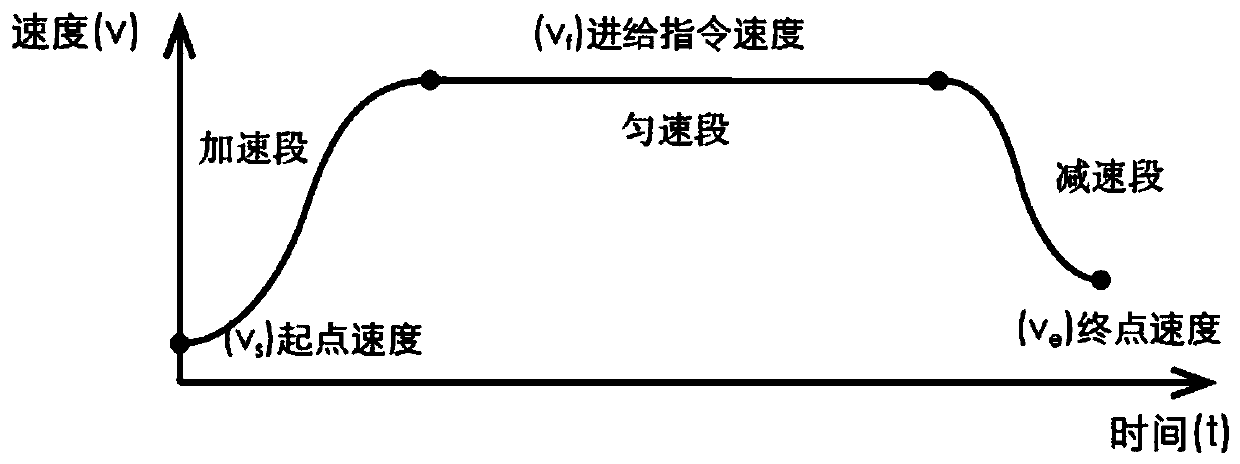

[0037] The acceleration and deceleration speed planning method of a CNC machine tool under the constant force constraint condition proposed by the present invention is different from the traditional numerical control system speed planning method based on kinematic parameters such as maximum speed, maximum acceleration and maximum jerk. The present invention uses power The scientific parameters - the maximum torque of the servo motor system (for rotary motors) or the maximum torque (for linear motors) are used as constraints for the speed planning of the CNC system. The concrete realization process of the inventive method is as follows:

[0038] 1) Obtain calculation parameters, including:

[0039] 1.1) Obtain the dynamic parameters of the servo feed system in the CNC system, including the maximum torque value (for rotary motors) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com