Particle Feeding System for Solar Cell Back Film

A technology of solar cells and feeding systems, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of low feeding and processing efficiency, and achieve the effect of improving feeding and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

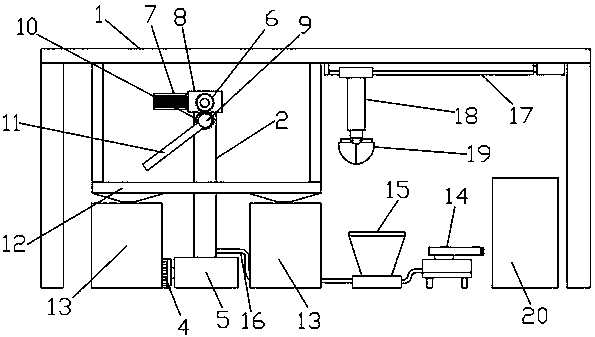

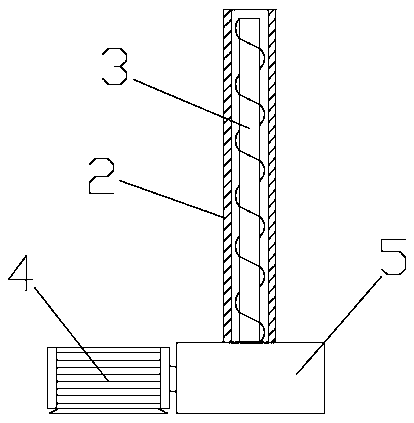

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the vertical feeding cylinder and threaded rod of the present invention, a particle feeding system for solar cell back film, including frame 1, vertical feeding cylinder 2, threaded rod 3, feeding motor 4, feeding speed reducer 5, driving gear 6. Gear drive motor 7, gear drive reducer 8, rotating cylinder 9, driven gear 10, discharge cylinder 11, diversion bin 12, mixing tank 13, air compressor 14, feeding hopper 15, pipeline 16, horizontal straight line Drive mechanism 17, vertical linear drive mechanism 18, automatic clamp bucket 19 and material storage box 20, the beam of the frame 1 is fixedly connected with the distribution bin 12, and more than two bins are arranged below the split bin 12 for stirring and mixing granular materials. The mixing tank 13, the bottom end of the vertical feeding cylinder 2 is fixed with a feed reducer 5, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com