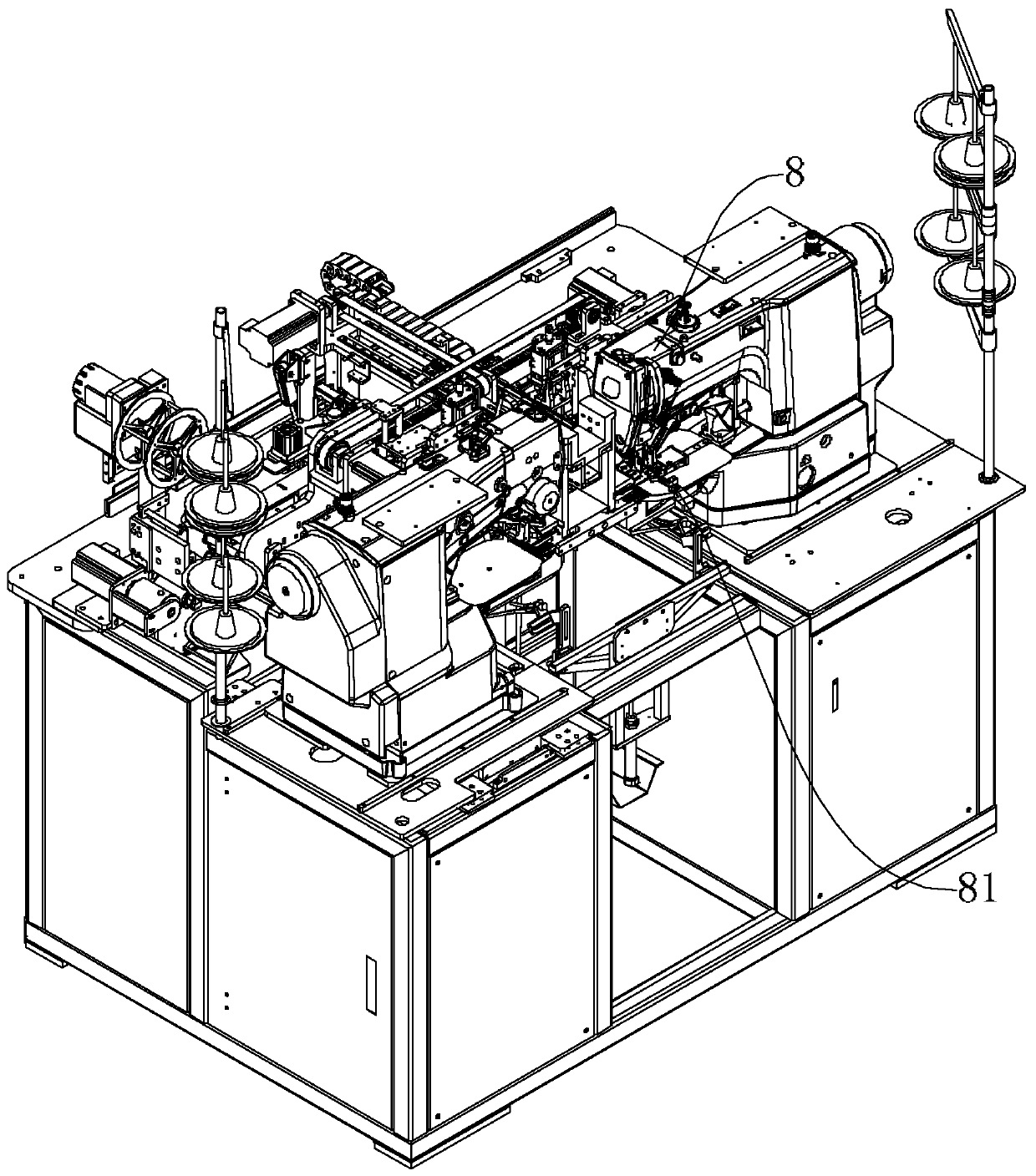

Feeding mechanism of waist strap bar-tacking machine

A technology of feeding mechanism and bar tacking machine, which is applied to cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problem that waist rope cannot be automatically fed, and achieve the effect of improving feeding processing efficiency and reducing labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

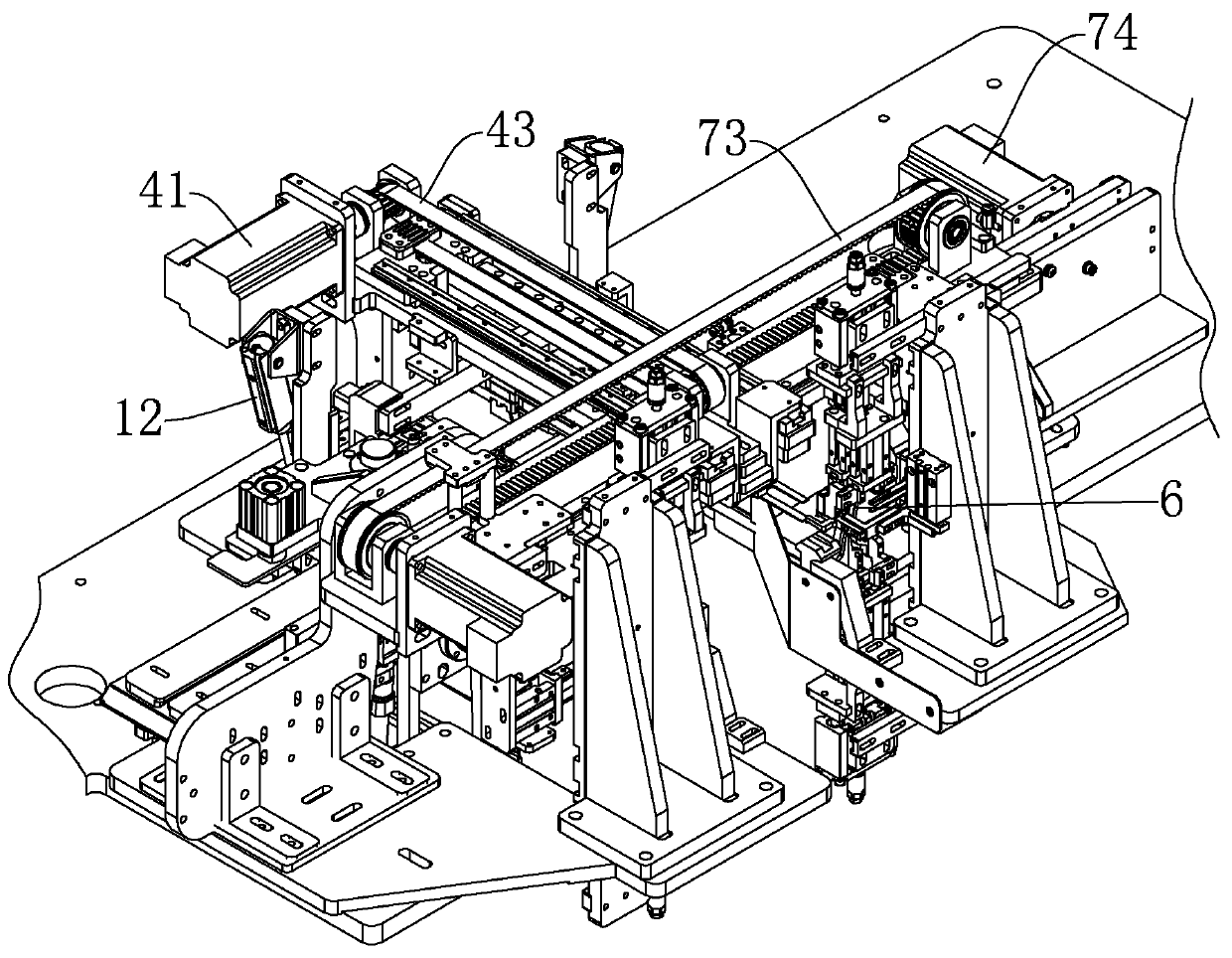

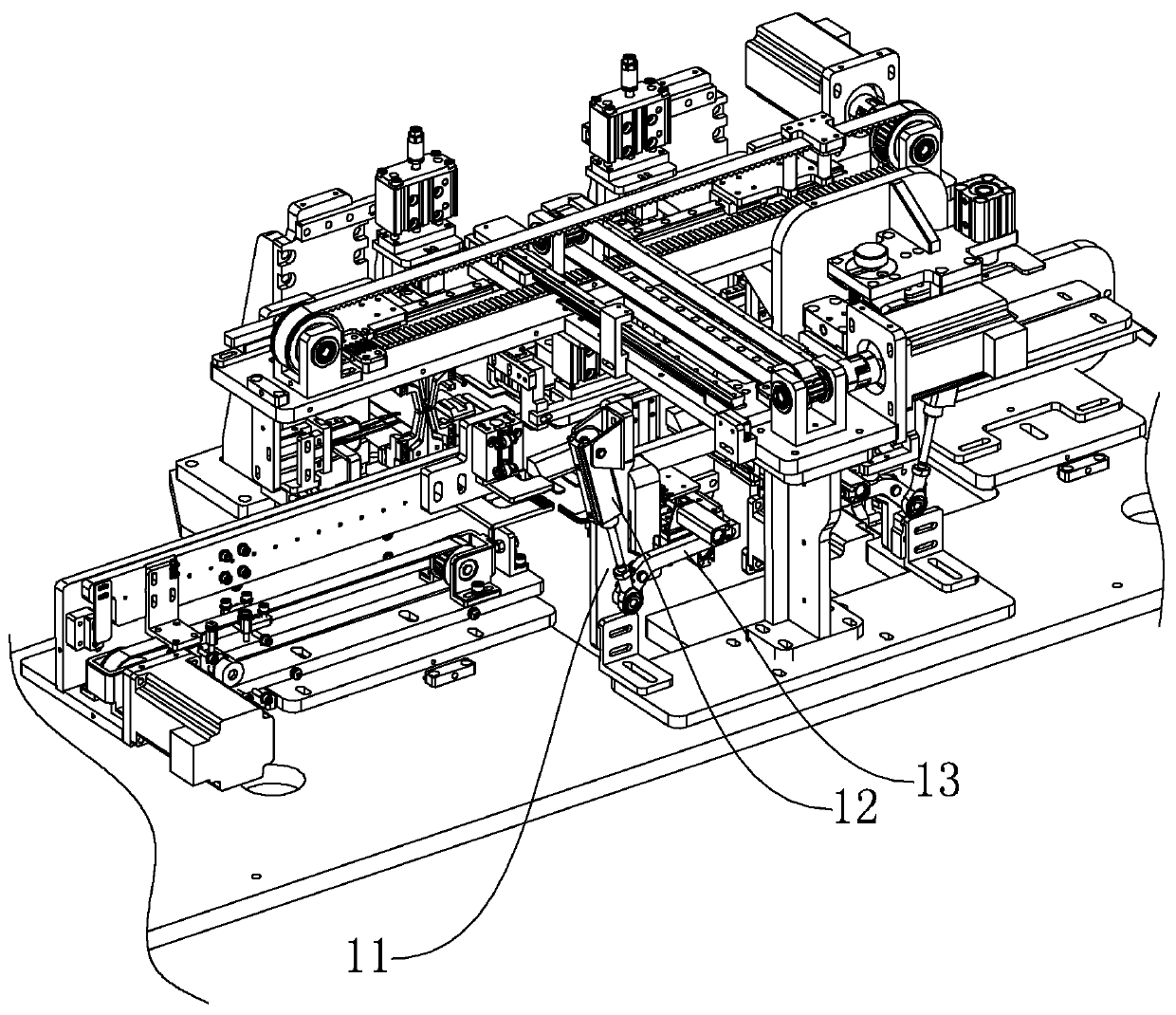

[0024] Figure 1 to Figure 10 Shown is the structural representation of the present invention.

[0025] The reference signs are: calibration pallet 1, pallet teeth 1a, calibration limit block 1b, calibration fixed bracket 11, calibration drive cylinder 12, pallet mounting frame 13, first cylinder 14, connecting plate 15, second Cylinder 2, waist rope limit block 21, first clamping assembly 31, second clamping assembly 32, first clamping plate 33, first clamping cylinder 34, second clamping plate 35, second clamping cylinder 36. Feeding mounting plate 4, feeding motor 41, feeding synchronous wheel 42, feeding timing belt 43, feeding bracket 44, feeding guide rail 44a, feeding slide 45, folding rod 5, folding rod driving cylinder 51, gripper assembly 6 , the first jaw driving cylinder 61, the first lifting cylinder 62, the first jaw 63, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com