Double-spindle full-automatic feeding and discharging device for three-way middle hole machining

A double-spindle, fully automatic technology, applied in metal processing, etc., can solve the problems of high equipment investment cost, affecting production efficiency, low efficiency and flexibility, etc., achieve low transformation investment cost, easy to use and implement, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

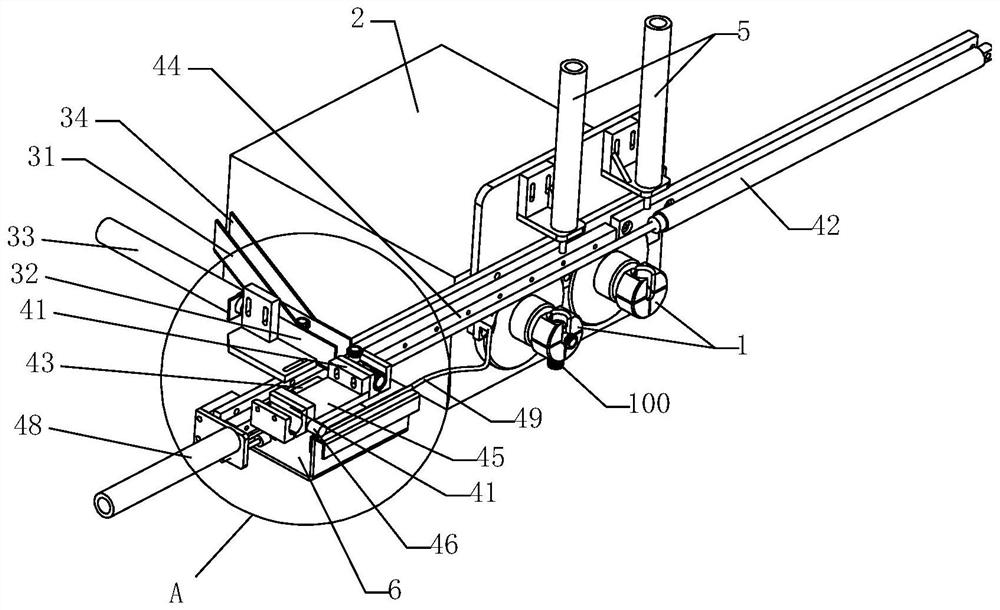

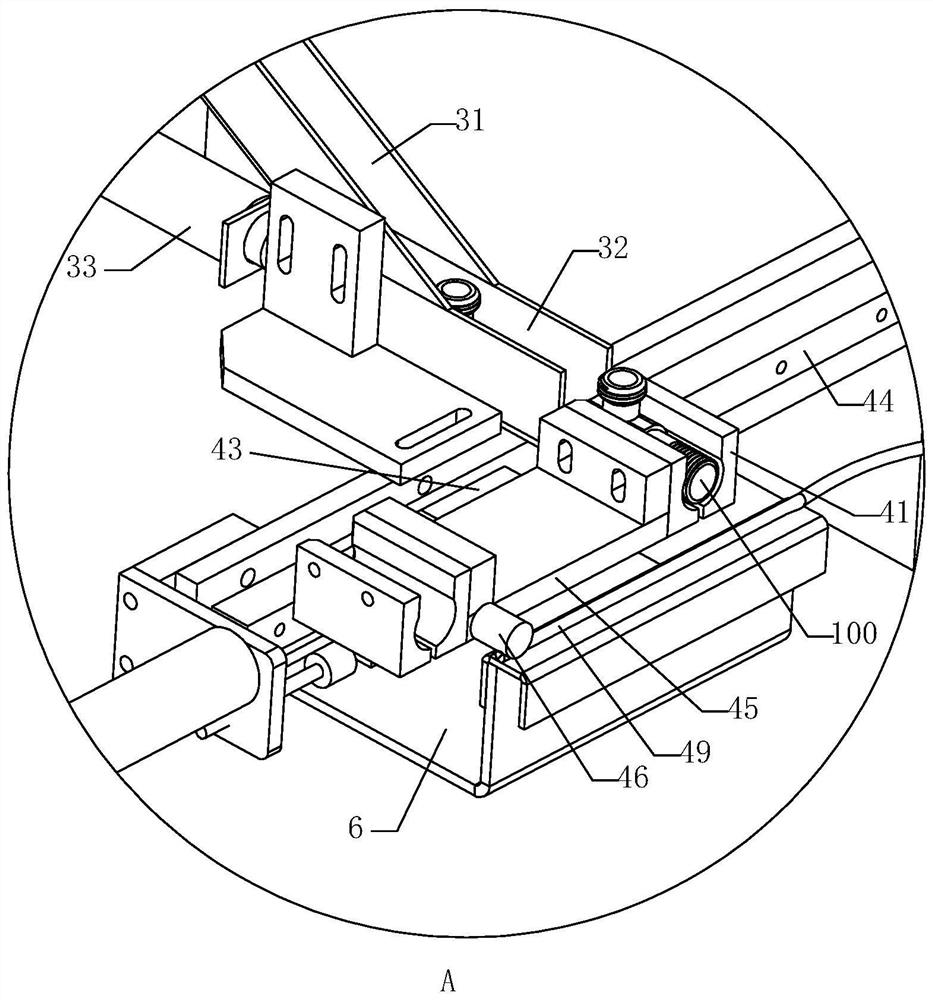

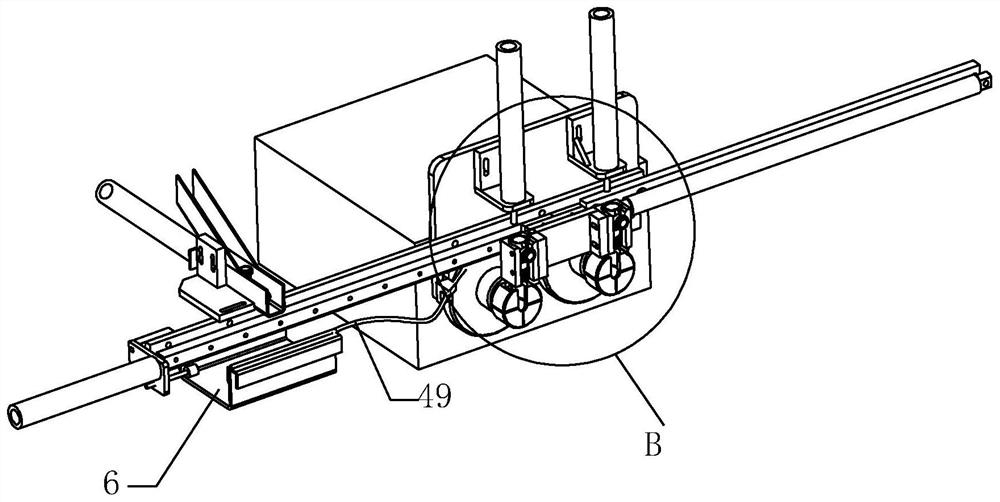

[0031] A double-spindle automatic loading and unloading device for three-way middle hole 103 processing, refer to figure 1 and figure 2 As shown, it includes a machine tool spindle box device 2 with a chuck 1, and a loading mechanism, a feeding mechanism, and a blanking mechanism are installed on the machine tool spindle box device 2. The feeding mechanism has a feeding port 34 for accessing the three-way pipe fitting 100 output by the vibrating plate, and the feeding mechanism has an elastic material clip 41 for receiving the three-way pipe fitting 100 and is used to complete the position state of the three-way pipe fitting 100 by twisting the track 49 From horizontal to vertical conversion action, the elastic material clip 41 is pushed by the blanking mechanism directly above the flush chuck 1 to realize the vertical entry of the three-way pipe fitting 100 into the chuck 1 . In the design, the elastic material clips 41 in the feeding mechanism, the beating cylinders 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com