Method for improving utilization rate of metal fuel cell anode

A technology of anode and metal plate, which is applied in the field of metal surface treatment, can solve the problems such as the reduction of thin metal utilization rate, and achieve the effect of improving utilization rate, improving utilization rate and flexible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

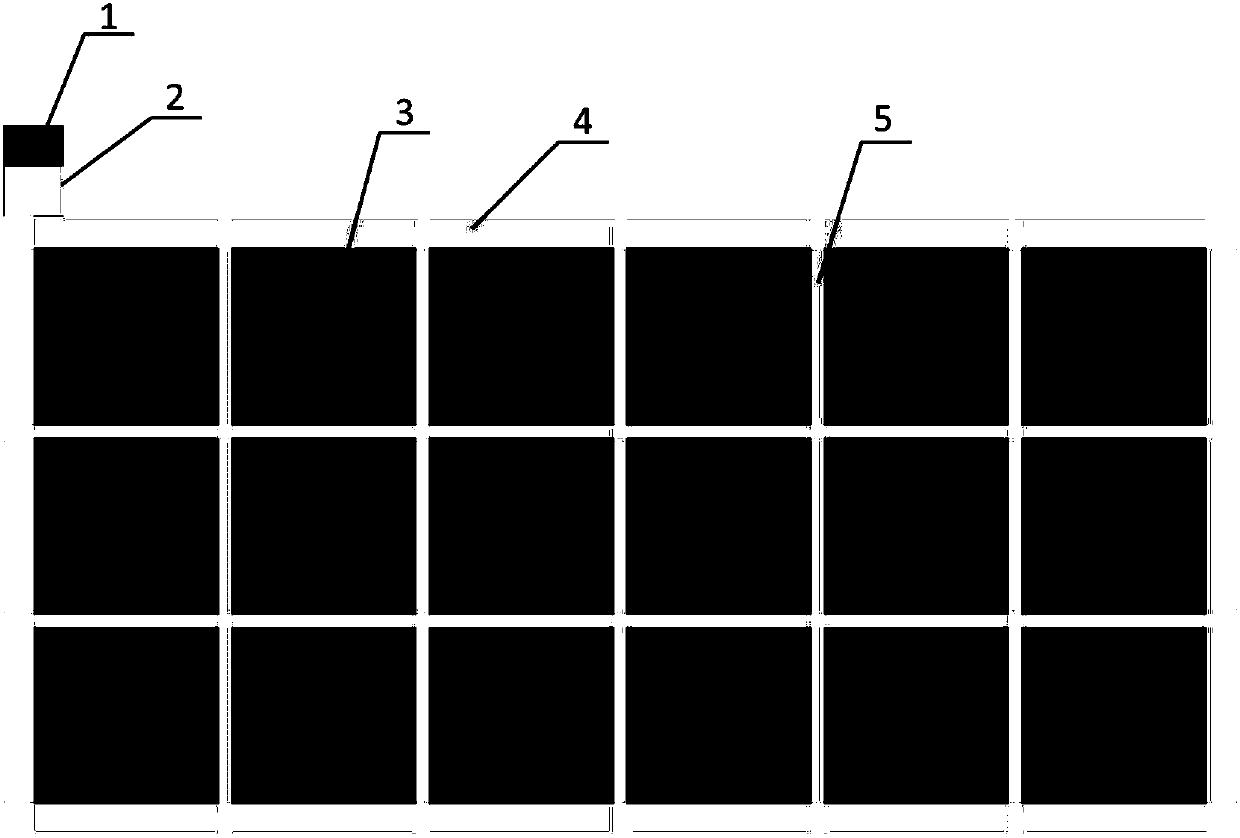

[0016] The schematic diagram of this embodiment is as follows figure 1 As shown, this scheme includes metal anodes and current collectors. The metal anode includes a tab for current collection and a metal anode body; the tab is a non-reactive area used as a current output conductor, and the metal anode body is a reaction area. The metal anode in the figure is a magnesium alloy AZ31B flat plate, its main body size is 200mm×100mm×0.4mm, and its tab size is 15mm×10mm.

[0017] The two surfaces of the metal plate are bonded horizontally and vertically with strip tapes to form a square grid pattern.

[0018] The current collecting net includes a main collecting net and a sub-collecting net; the tape width of the main collecting net is 5mm, and the tape width of the sub-collecting net is 2mm.

[0019] The material of the original film of the tape is a biaxially oriented polypropylene film with a thickness of 20m, a tensile strength of 150MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com