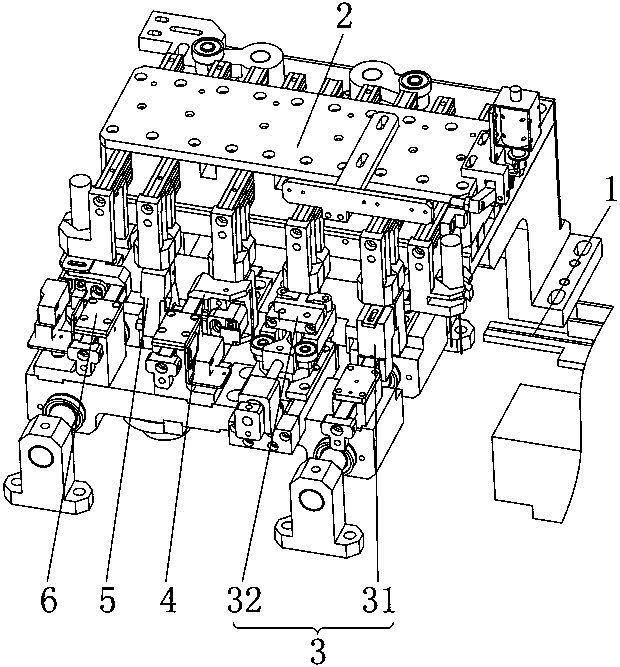

Full-automatic sleeve pin-shearing method for lithium battery and sleeve pin-shearing machine

A lithium battery, fully automatic technology, applied in the direction of primary battery, secondary battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of complex cost of equipment, increase of defective products, polarity error, etc., and achieve the goal of improving product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

[0037] The following is a fully automatic casing cutting method for a lithium battery provided by the present invention, which includes the following steps:

[0038] Step 1. Put the lithium battery into the slit transfer device to smooth the lead posture of the lithium battery. The lead of the lithium battery is passed forward by the transfer device under the guidance of the slit, so that the lead posture of each lithium battery same;

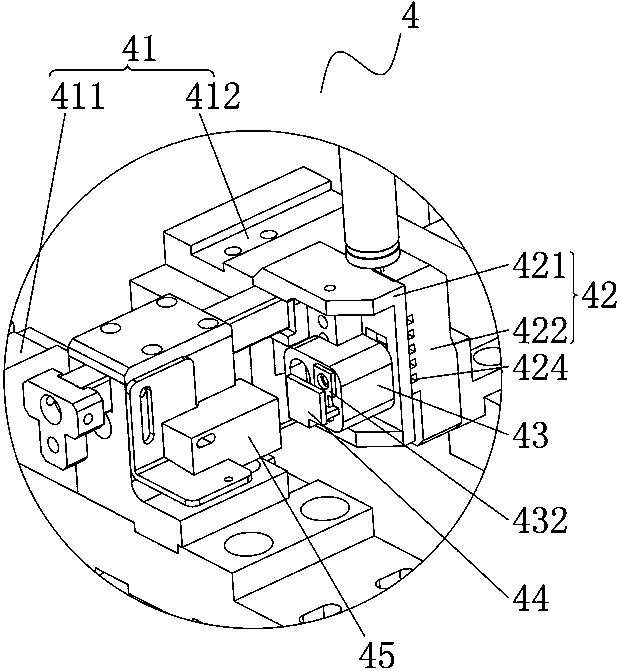

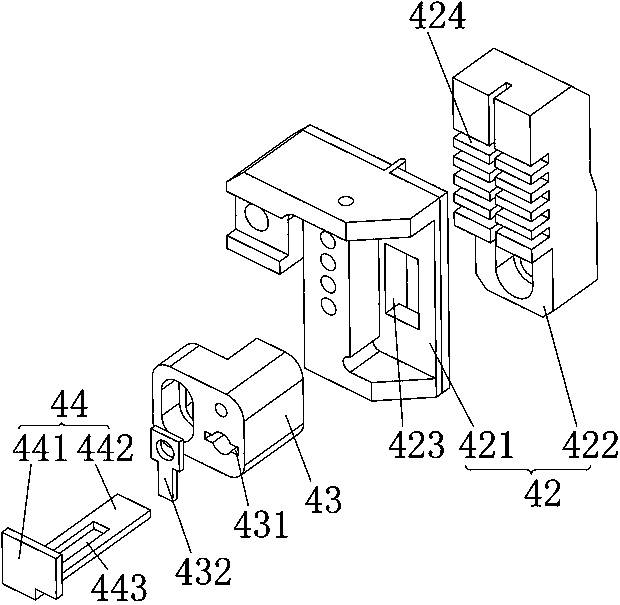

[0039] Step 2. Transfer the lithium battery to the leg fixing device to make the leg of the lithium battery, so that the two pins of the lithium battery are arranged to be parallel to each other and perpendicular to the end face of the lithium battery, so that the subsequent detection station can detect the pins. foot;

[0040] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com