Multi-occasional application waste gas purifying device for environmental protection engineering

A technology of exhaust gas purification device and environmental protection engineering, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of single exhaust gas purification function, no exhaust gas dredging, and no exhaust gas dust cleaning function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

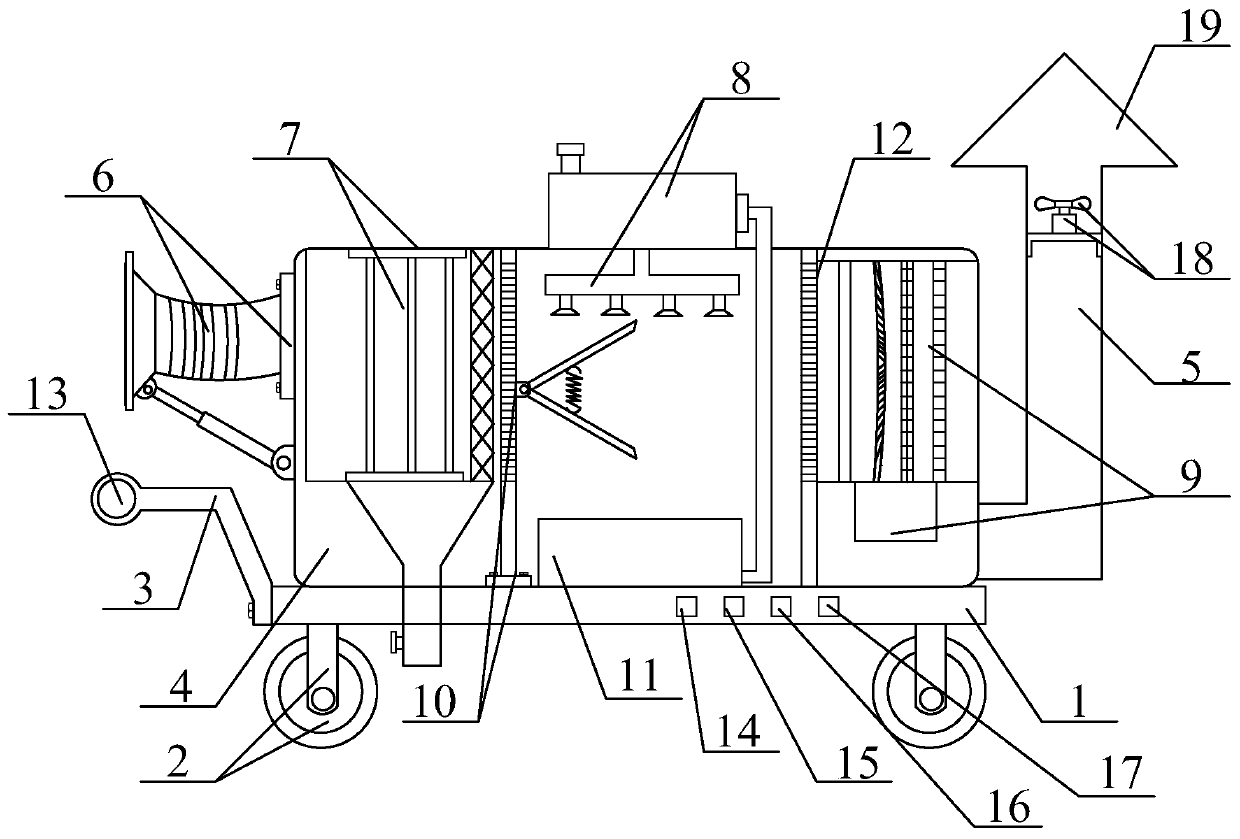

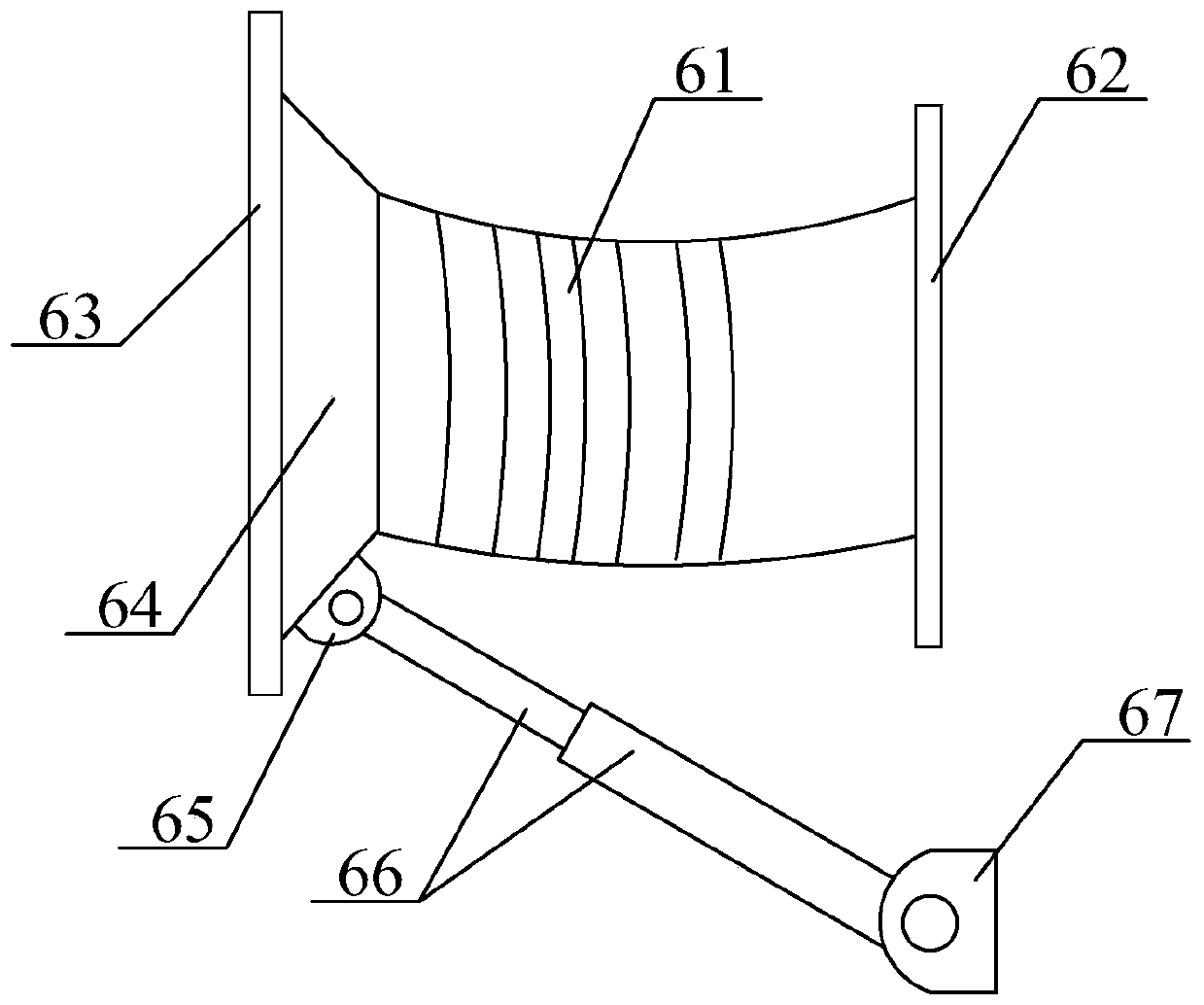

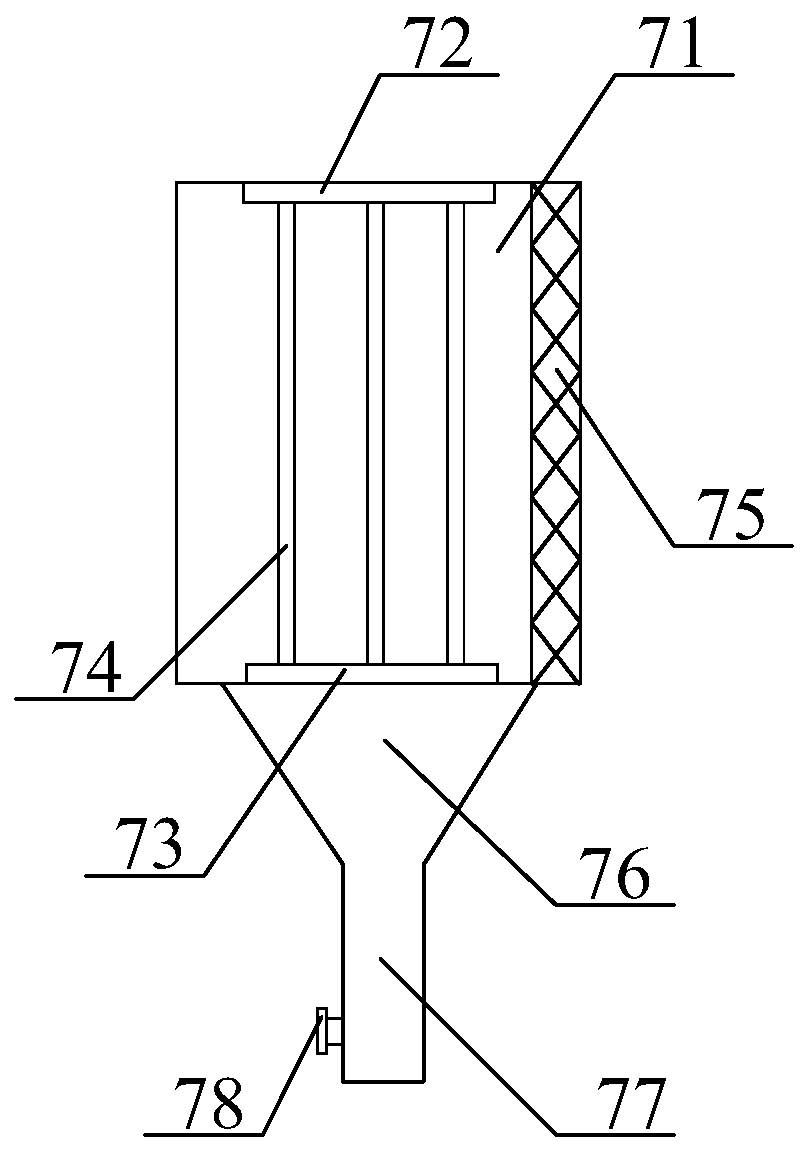

[0043] as attached figure 1 To attach figure 2 As shown, the present invention provides a waste gas purification device for environmental protection engineering used in multiple occasions, including a mobile tray 1, a mobile roller 2, a draw bar 3, a purification box 4, and an exhaust chimney pipe 5, which is conveniently connected to an adjustable intake bellows Structure 6, electrostatic exhaust gas dust removal box structure 7, recyclable exhaust gas neutralization spray box structure 8, exhaust gas purification cylinder structure 9, diversion partition plate structure 10, waste liquid recovery box 11, partition main board 12, traction hole 13, Suction connection control switch 14, electrostatic precipitator control switch 15, spray cycle control switch 16, exhaust control switch 17, exhaust fan 18 and protective cover 19, the moving rollers 2 are respectively bolted to the four corners of the lower surface of the moving tray 1 position; the drawbar 3 bolts are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com