Patents

Literature

38results about How to "To achieve the purpose of purifying exhaust gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

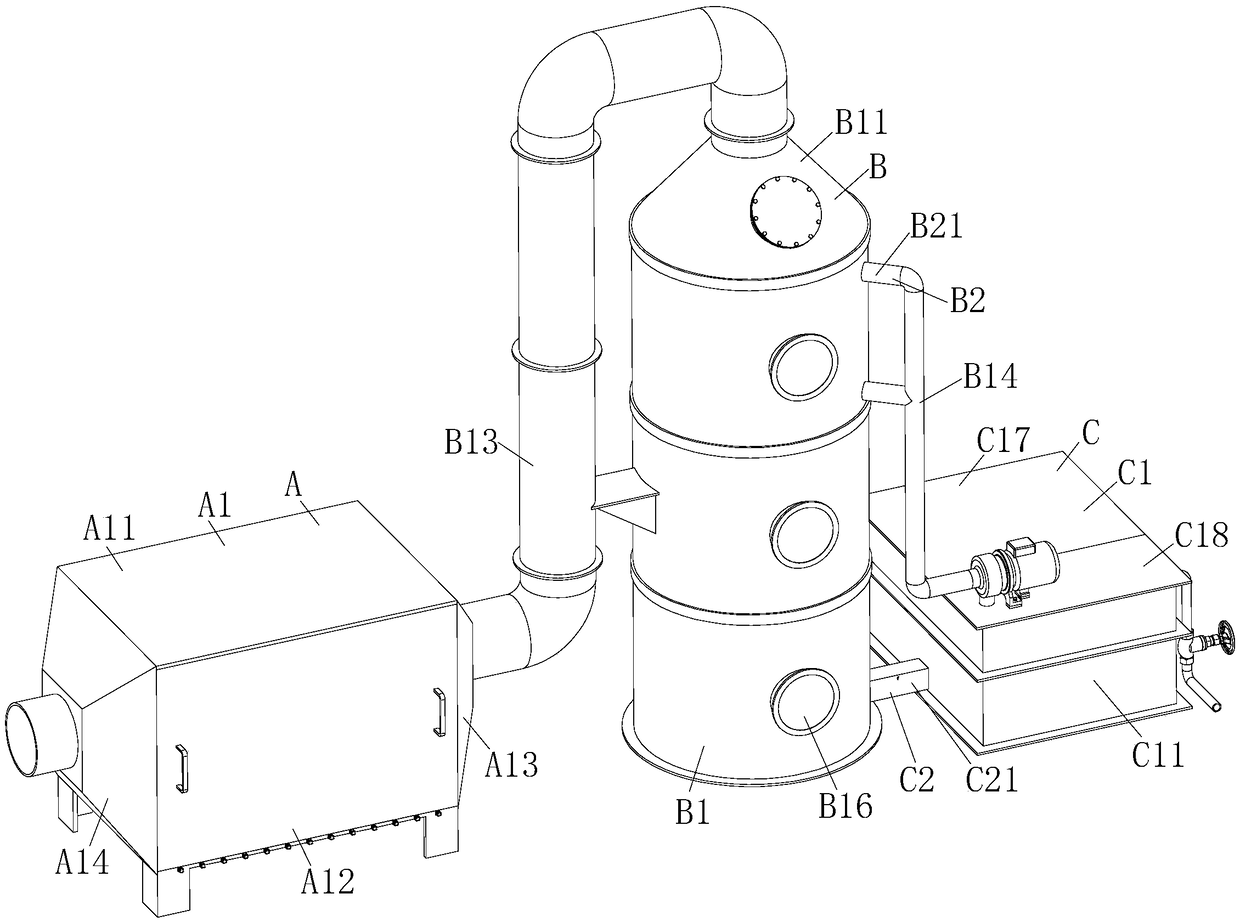

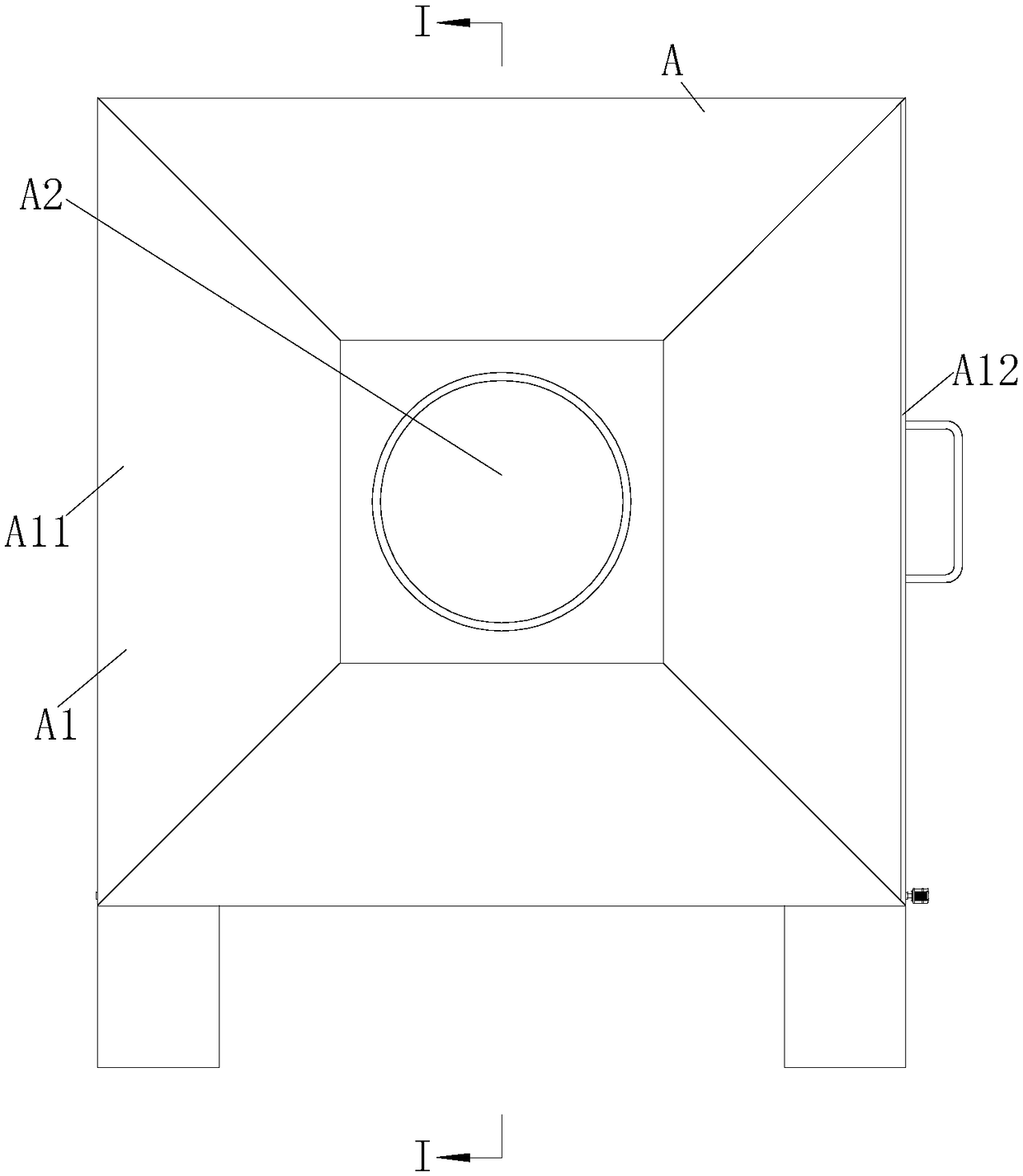

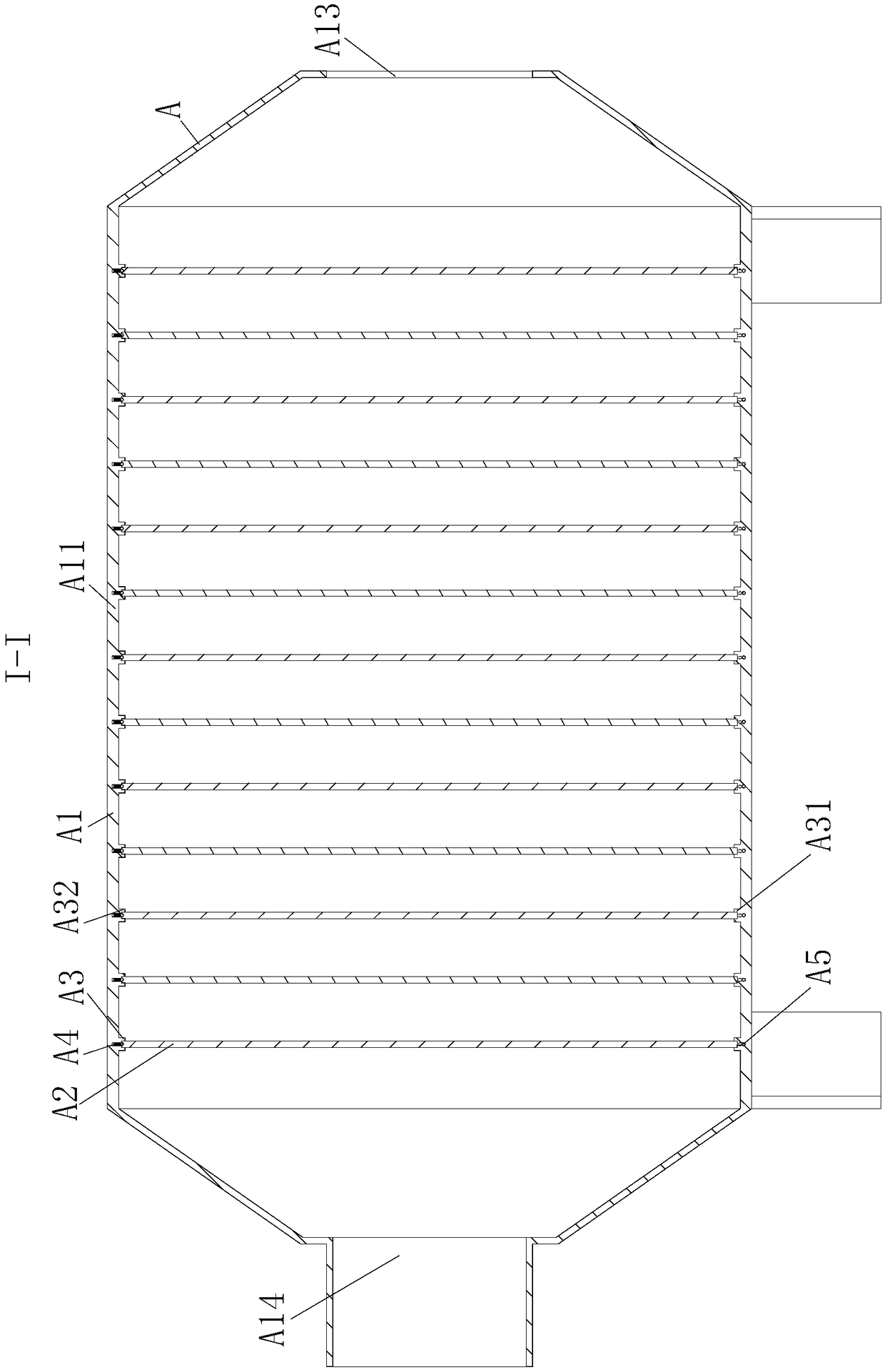

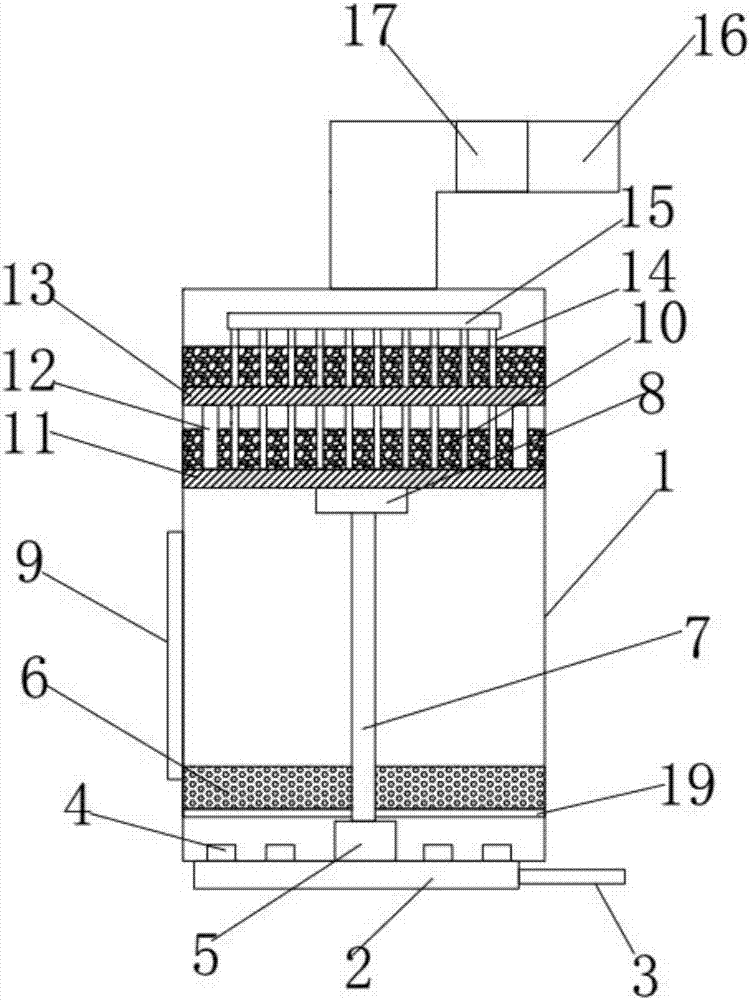

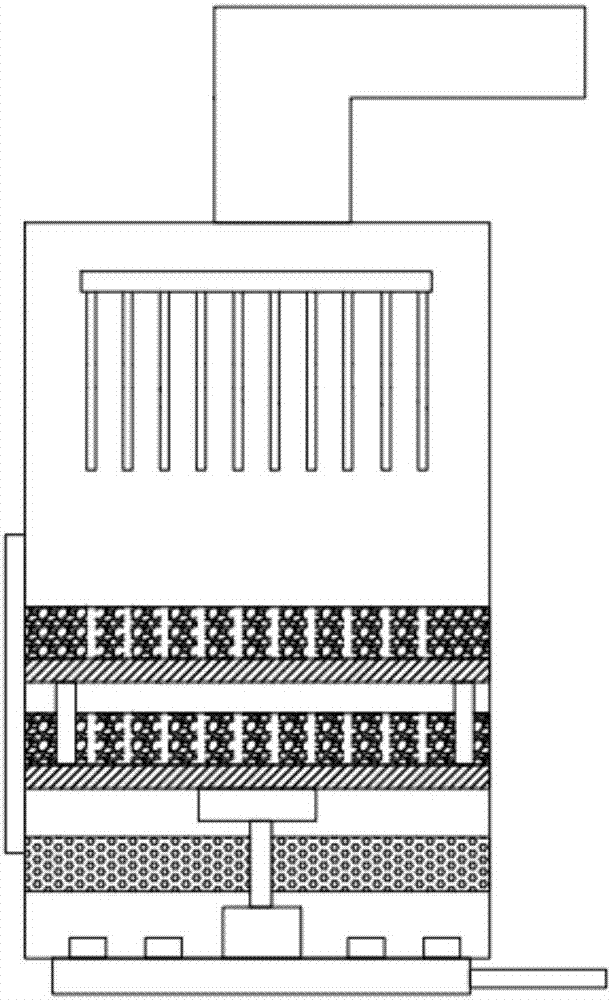

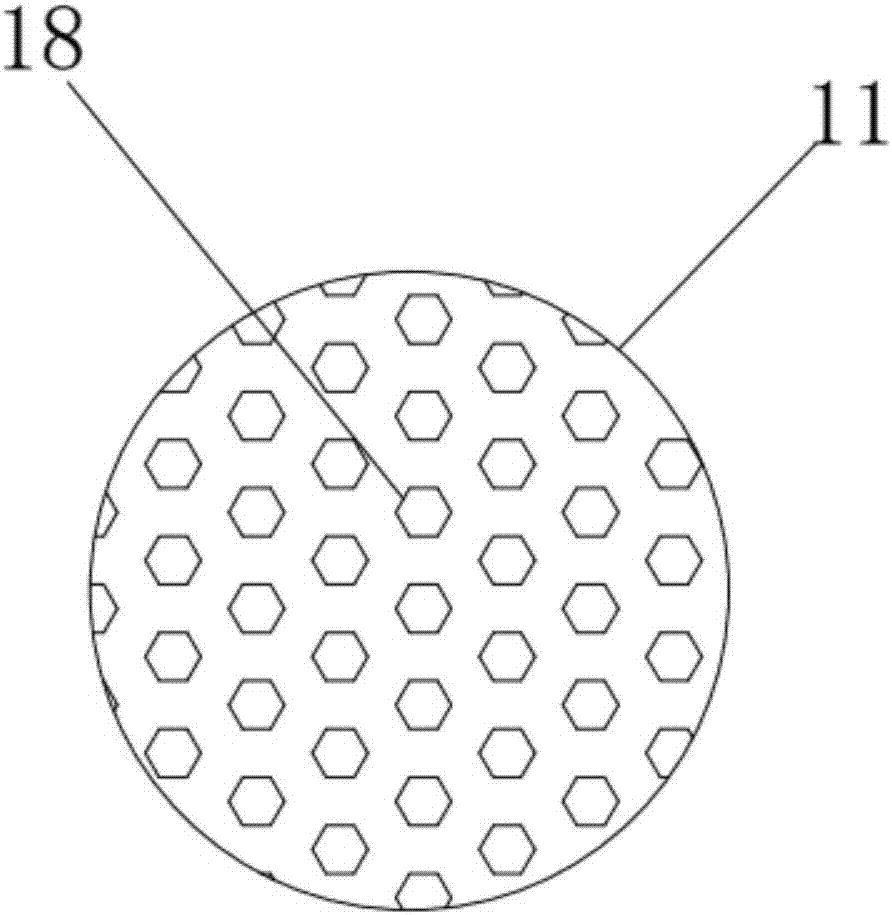

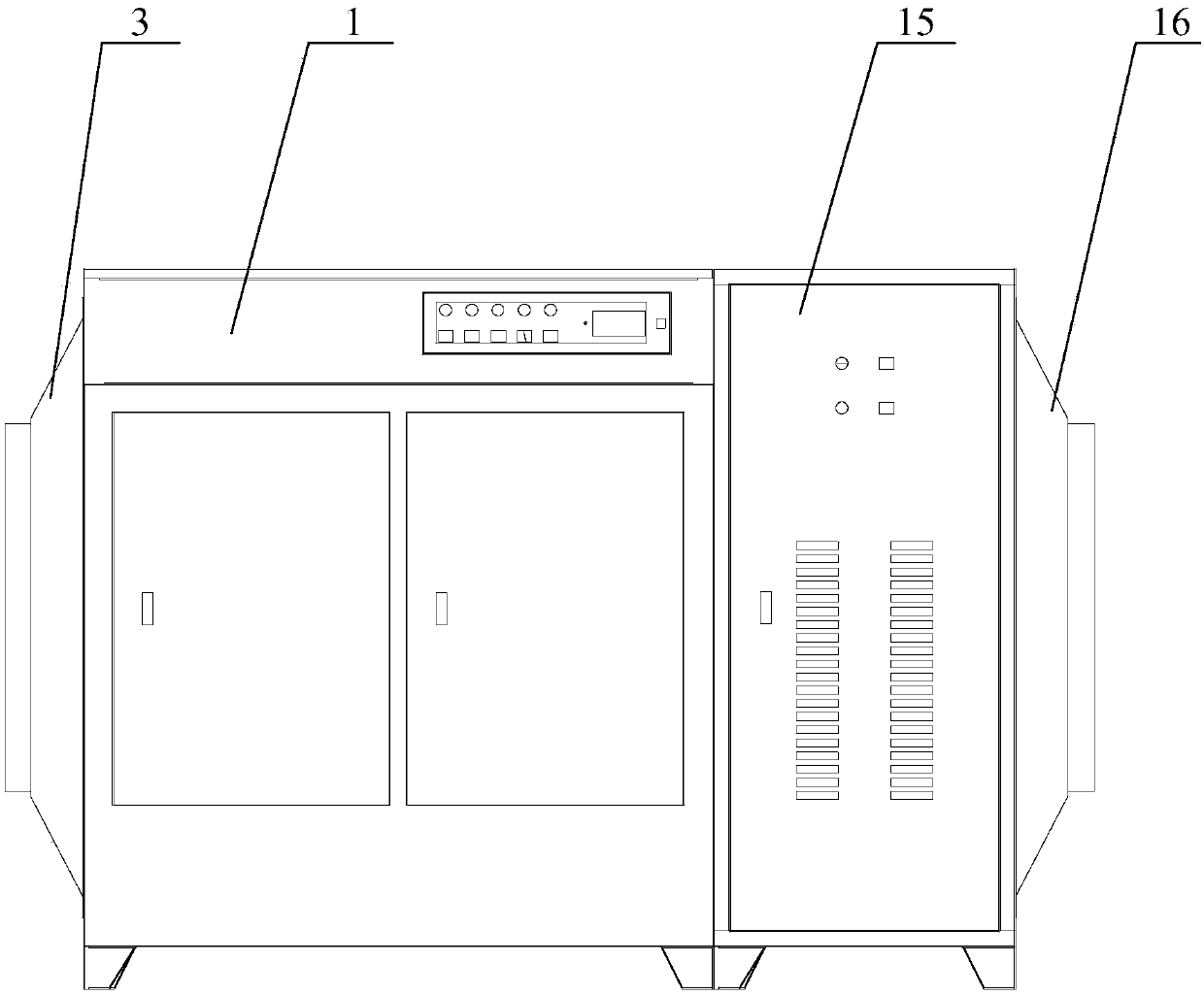

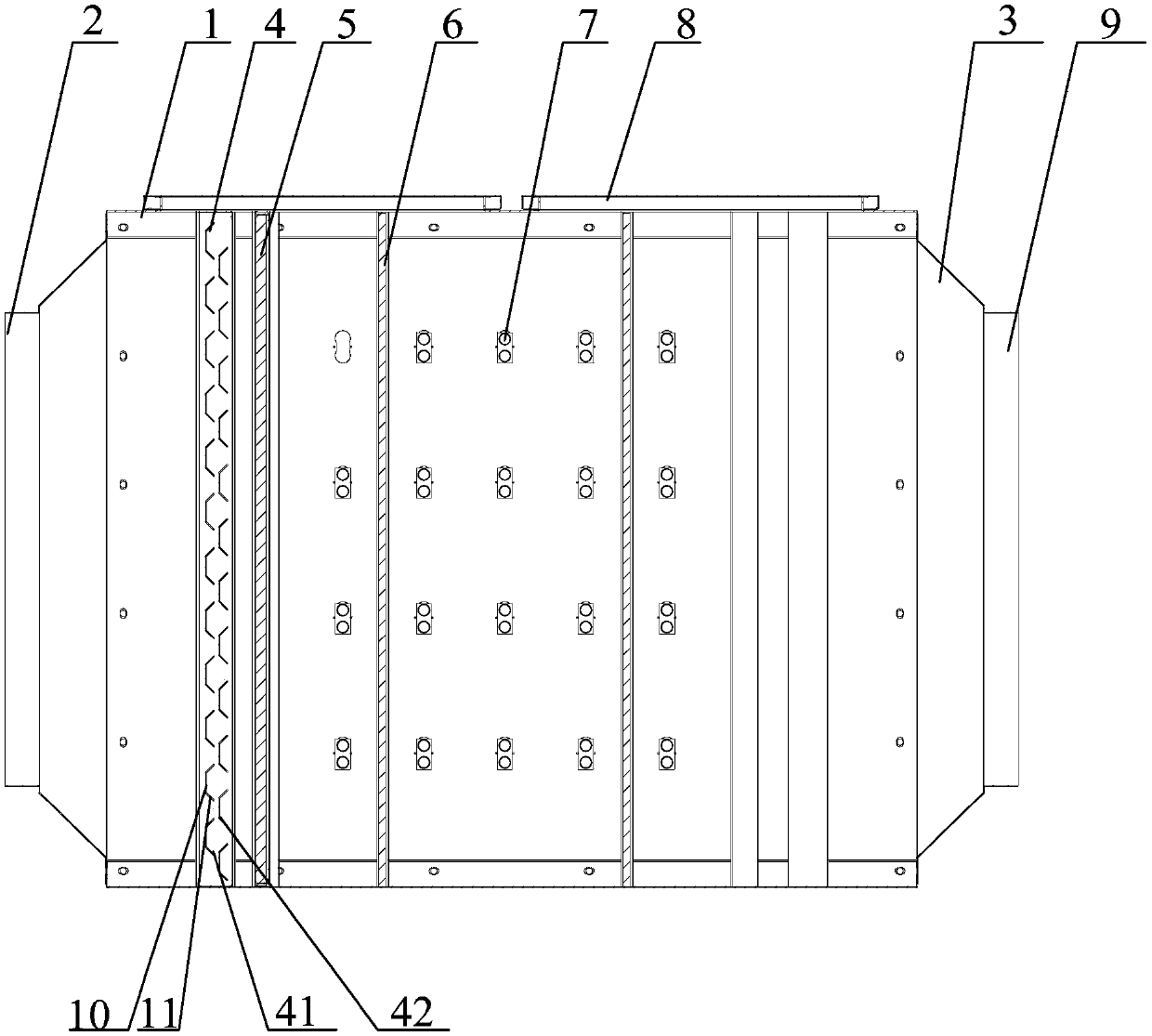

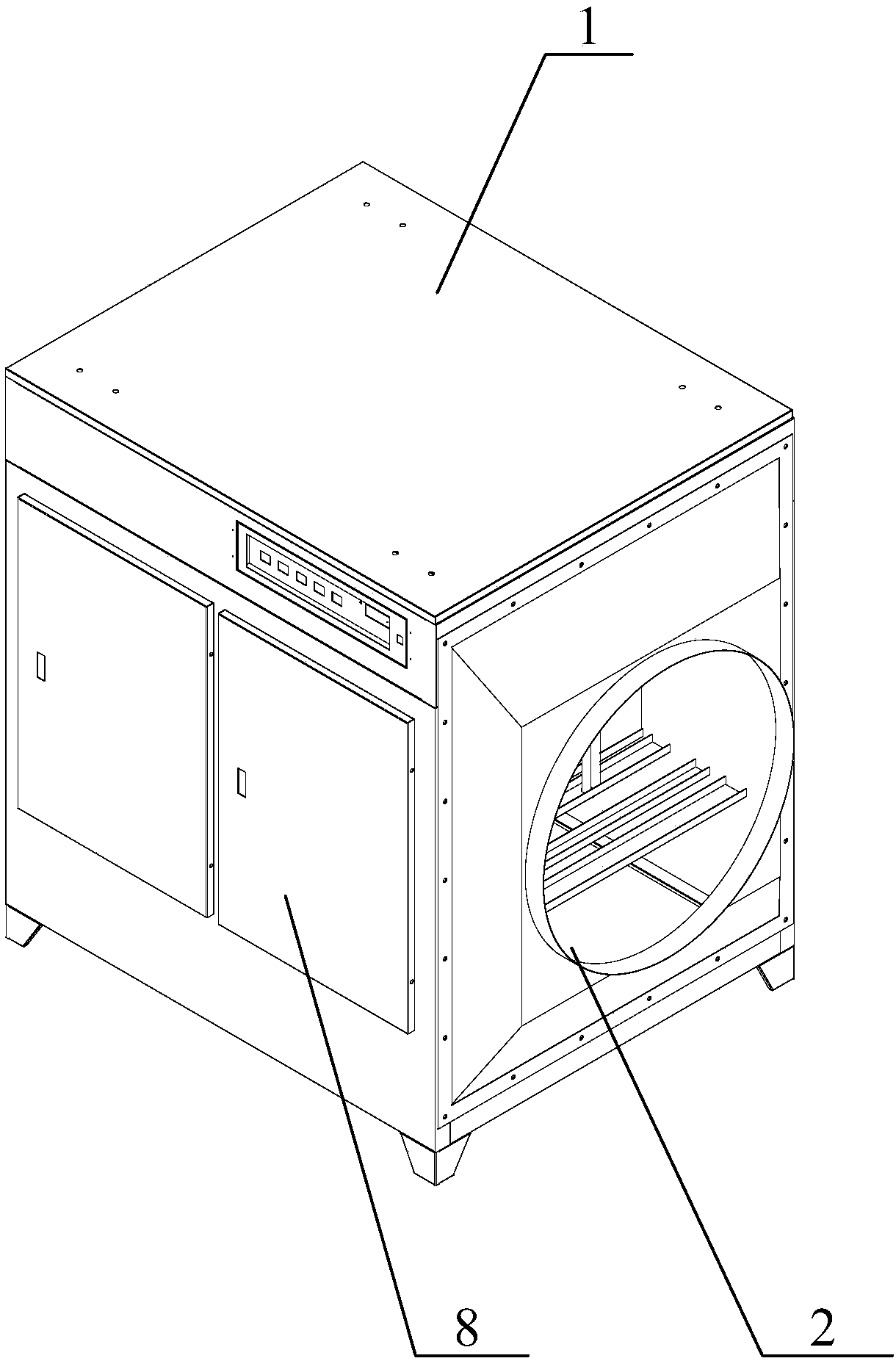

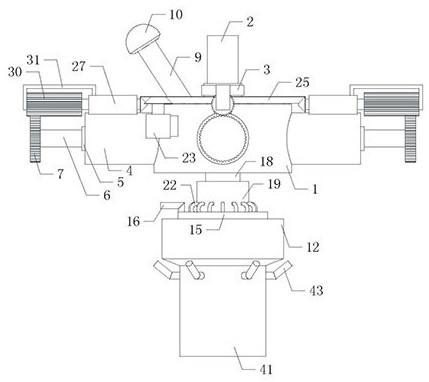

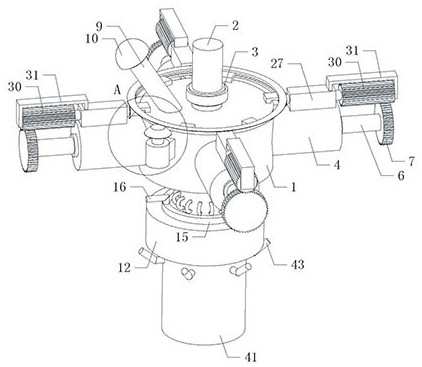

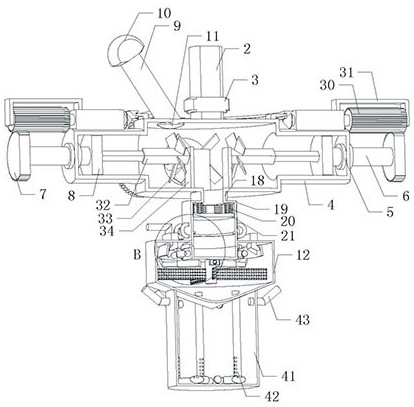

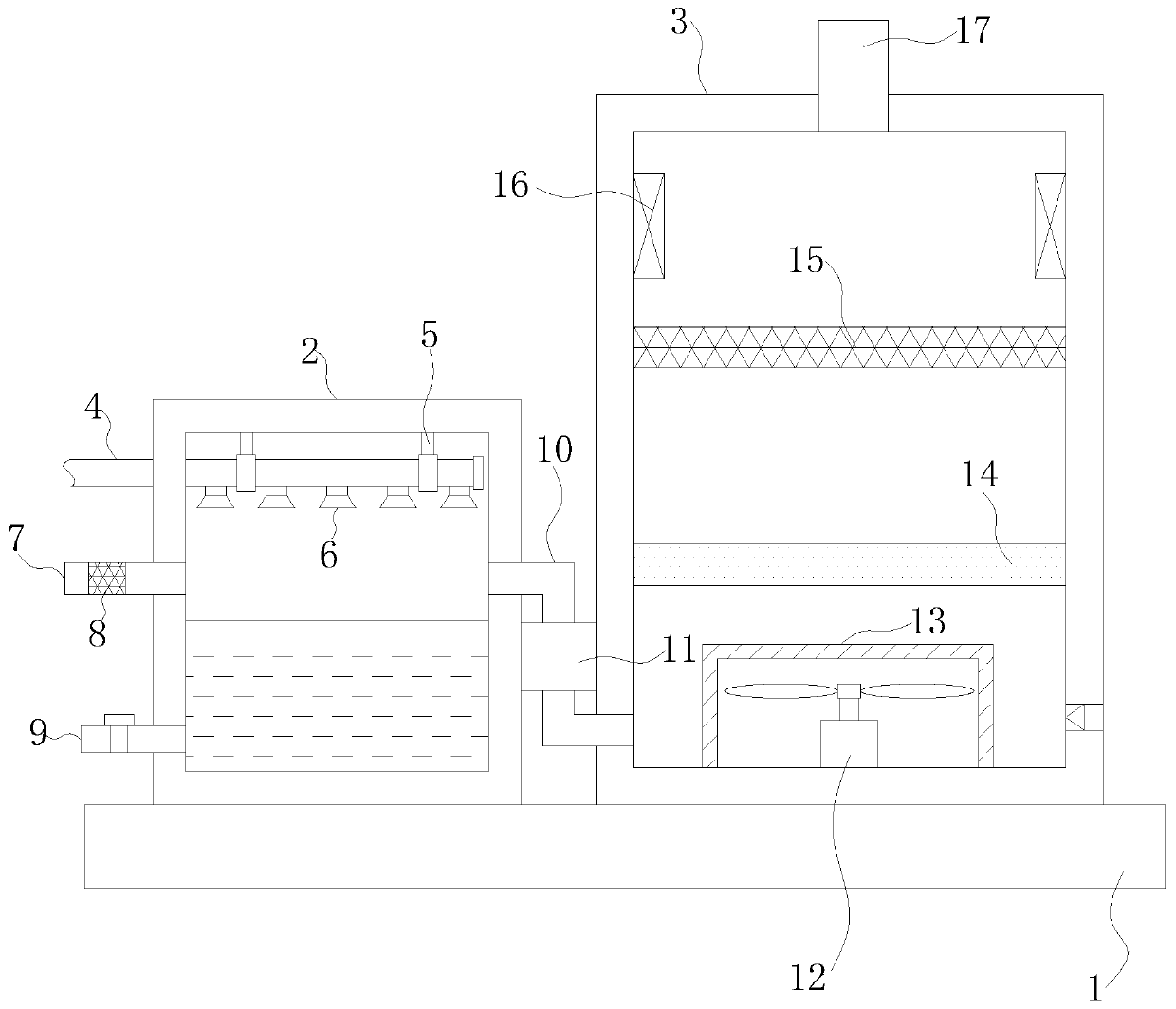

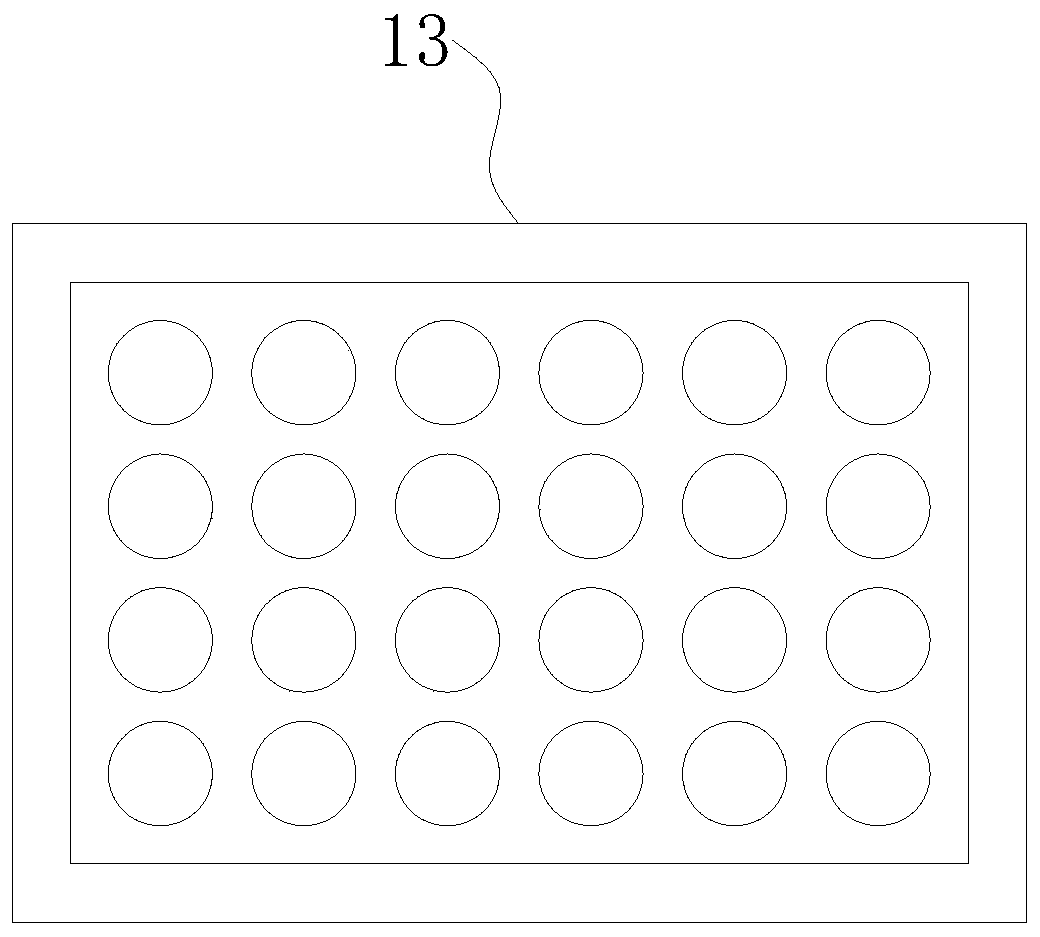

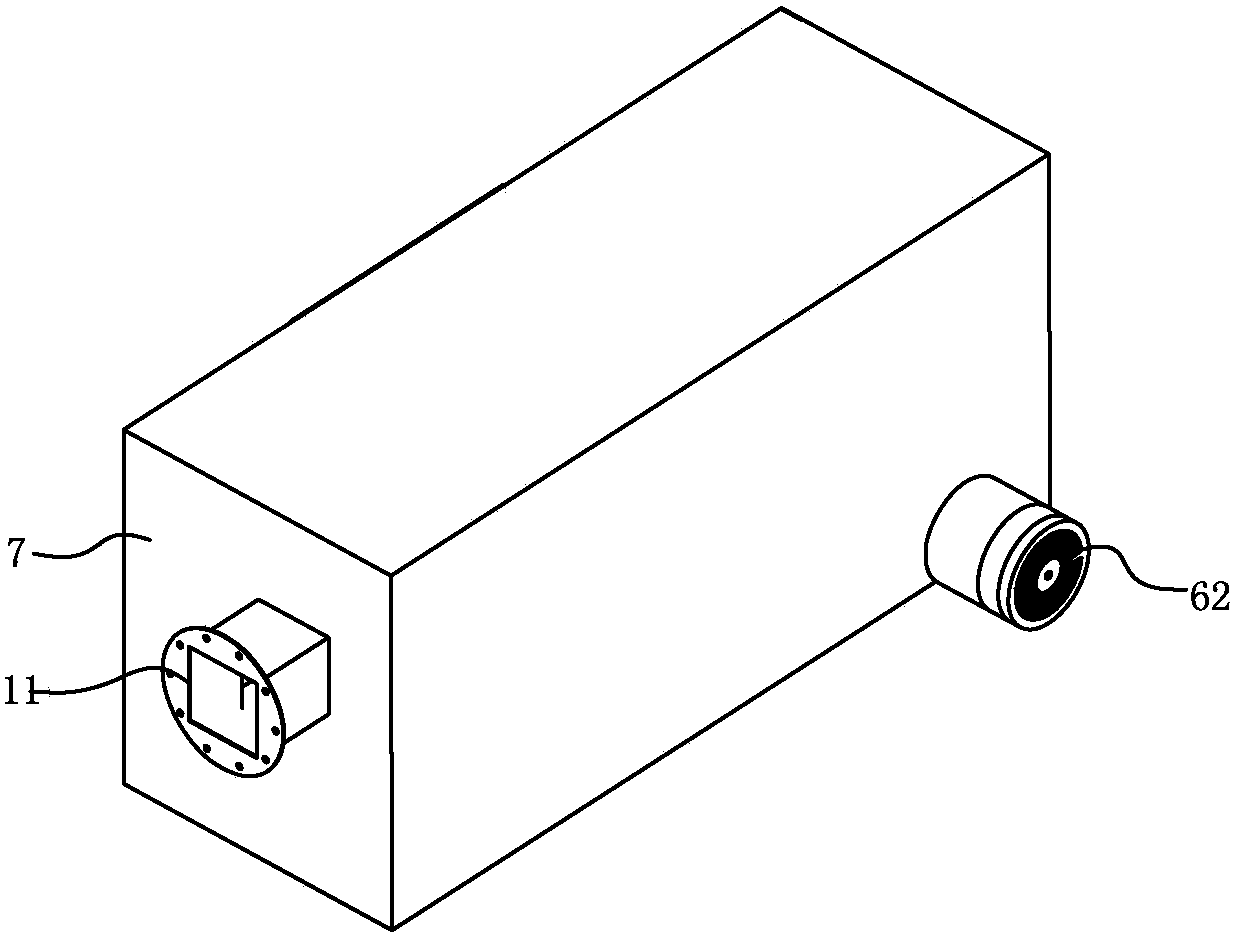

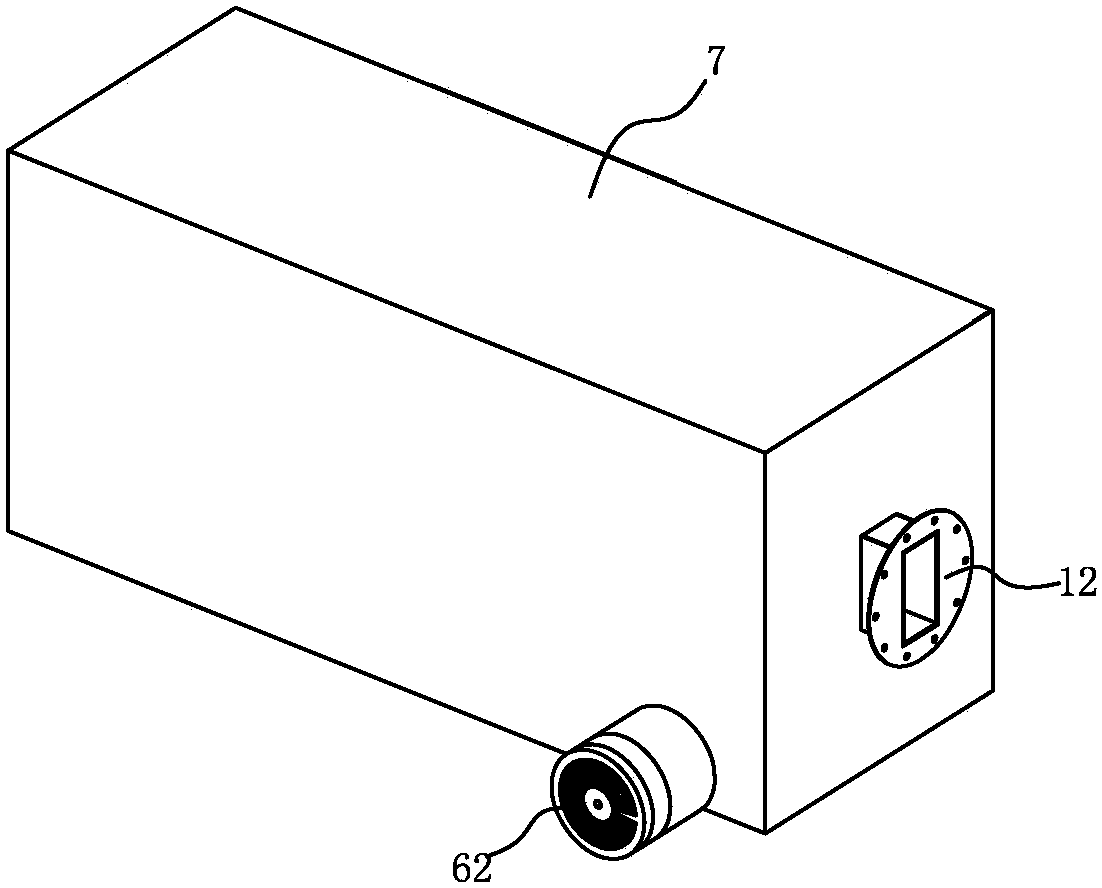

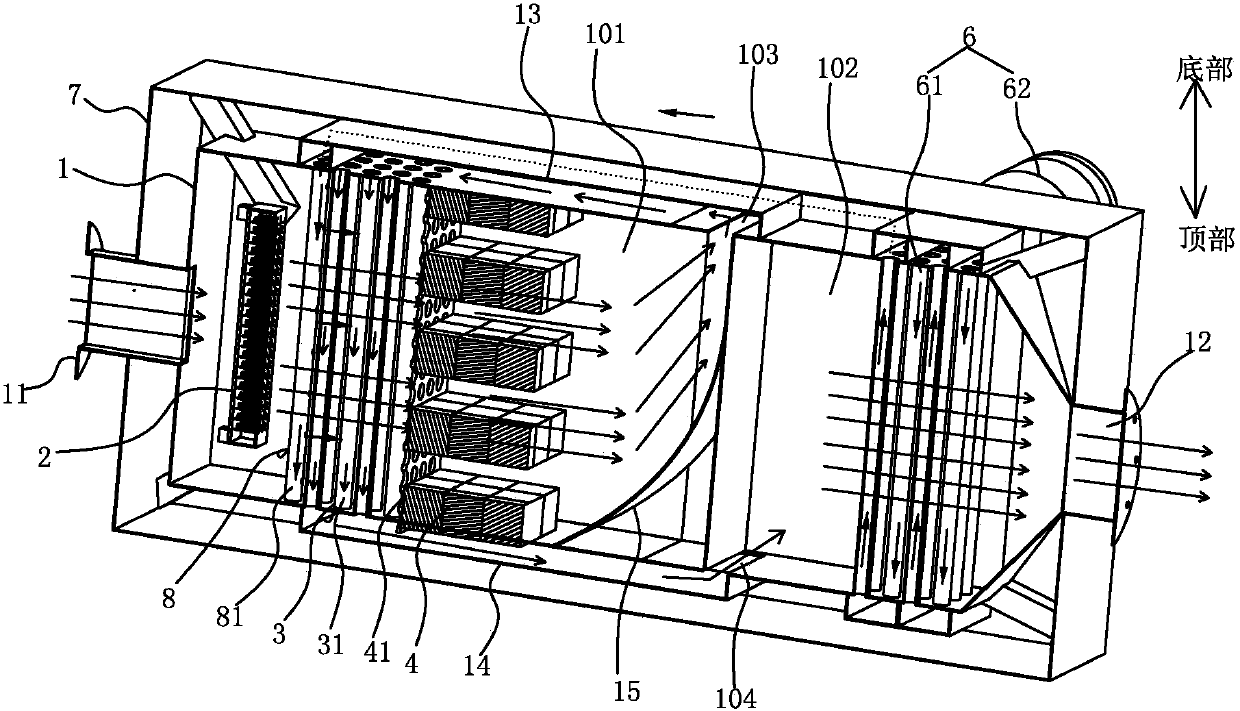

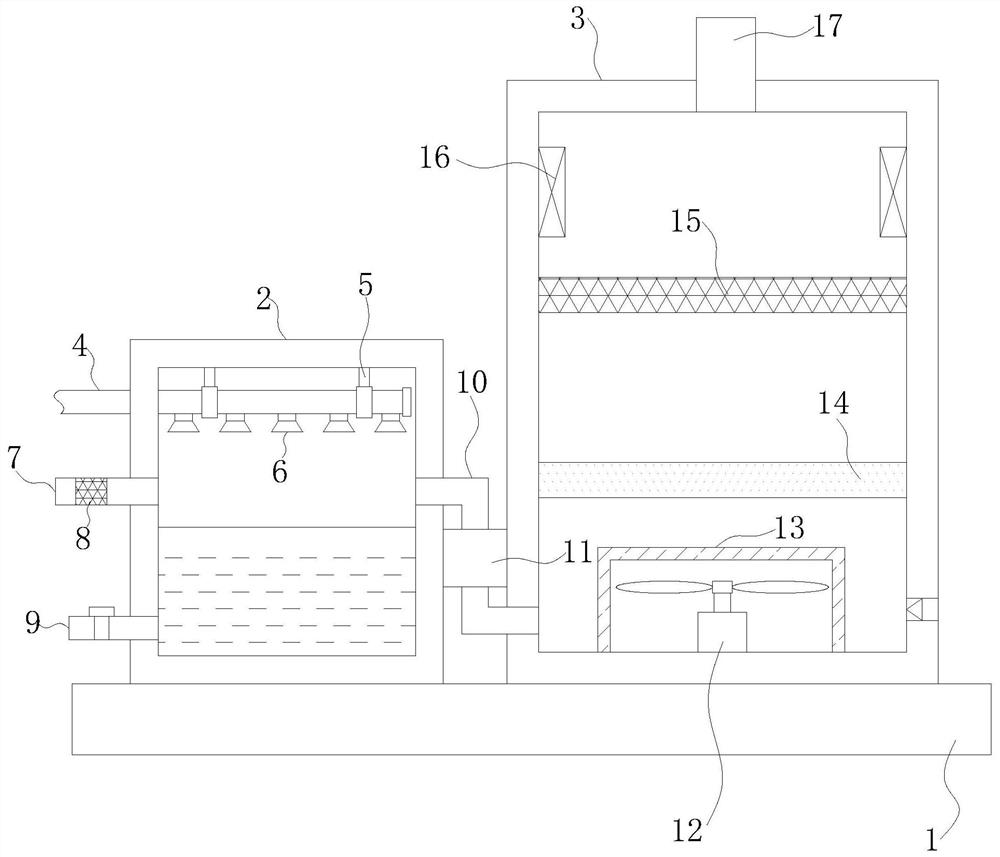

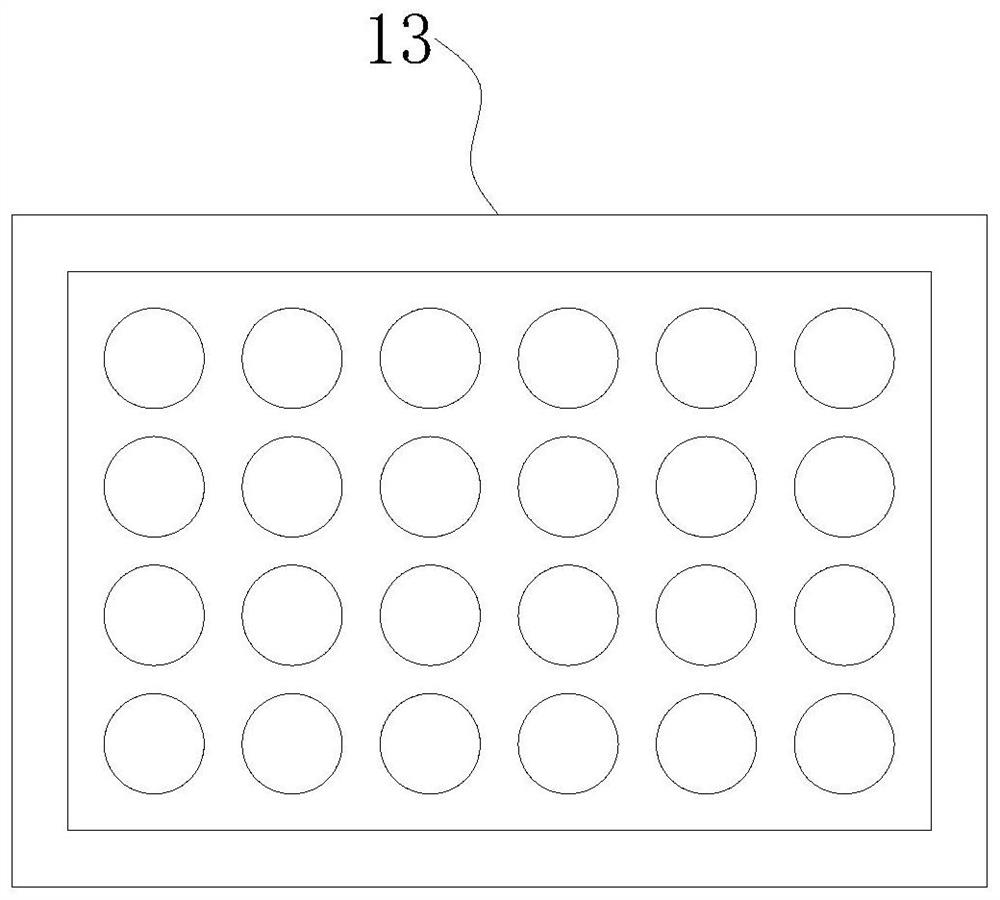

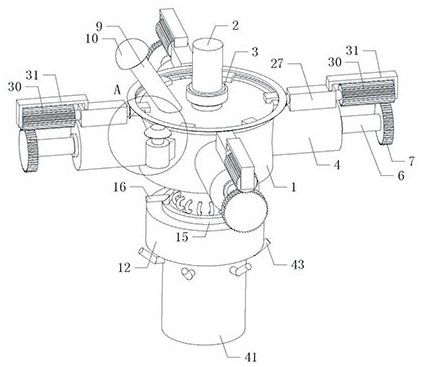

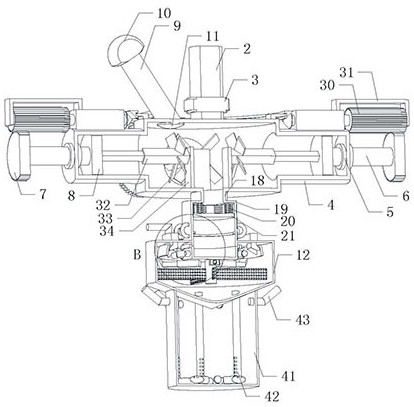

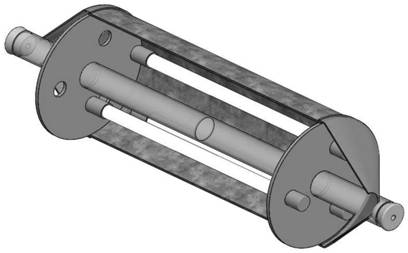

Waste gas treatment equipment and method

PendingCN109364687AFull spraySpray evenlyUsing liquid separation agentSeparation devicesActivated carbonSludge

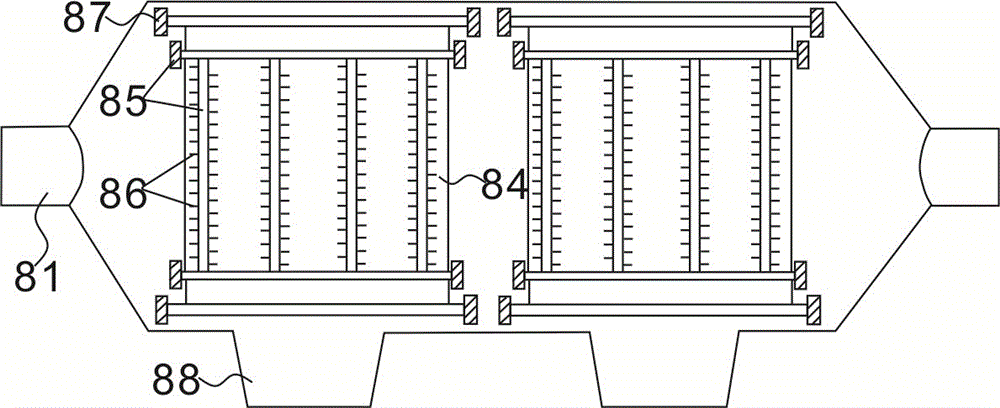

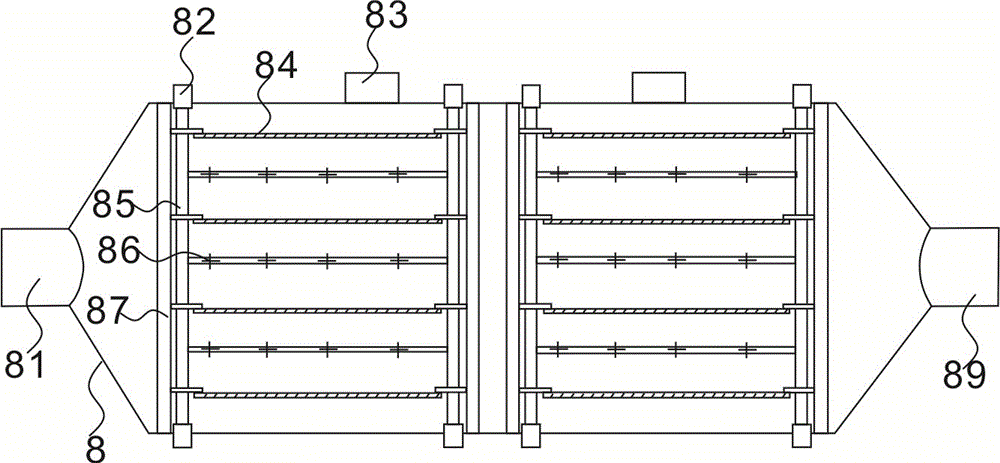

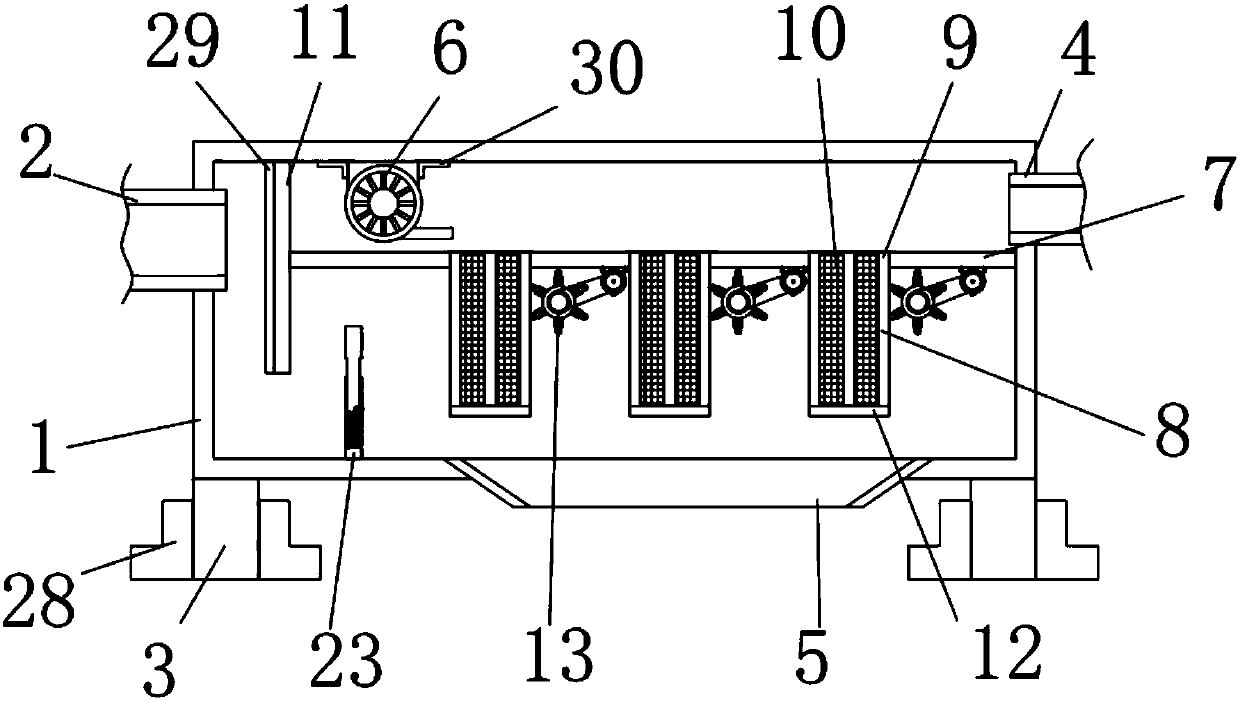

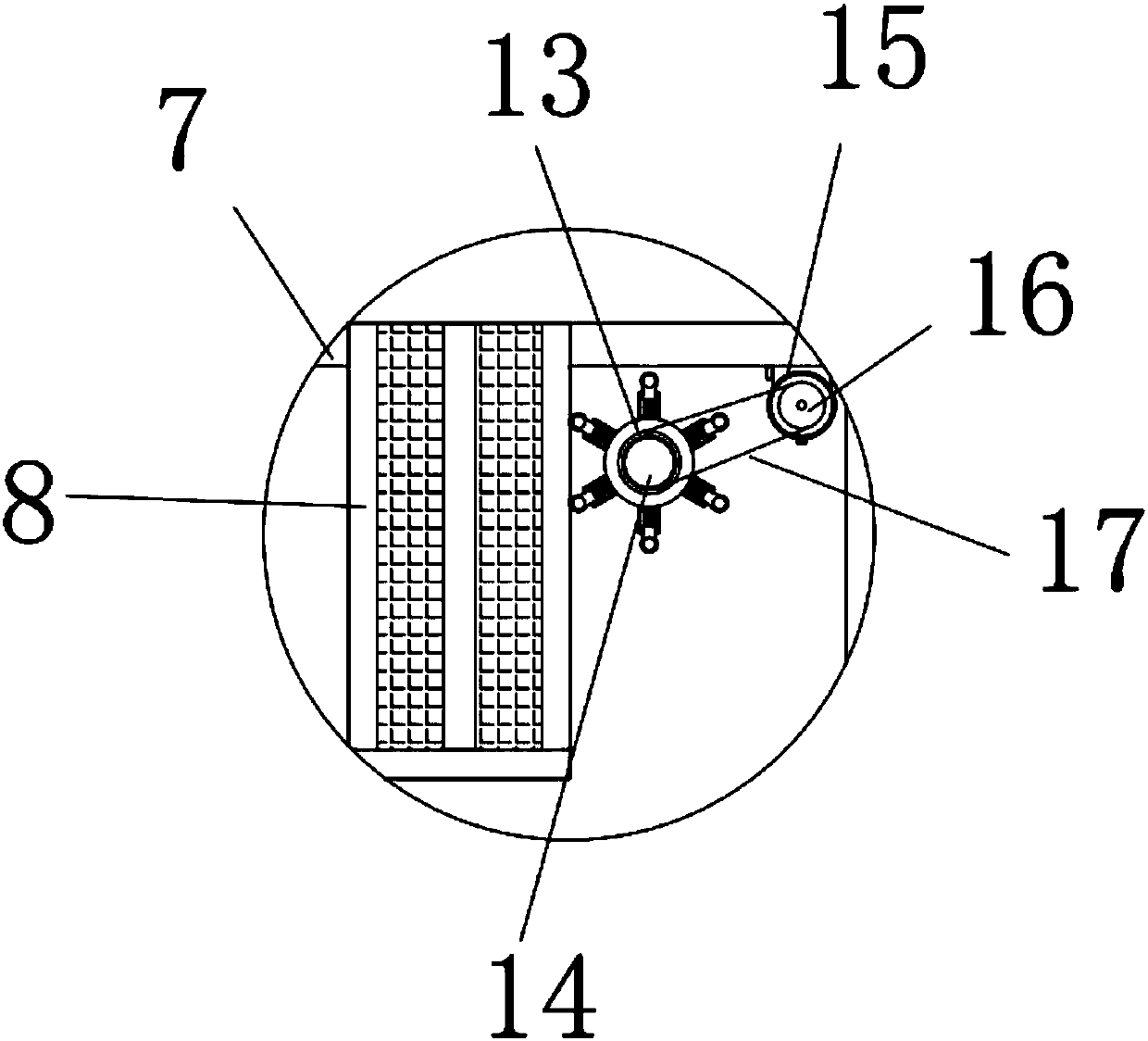

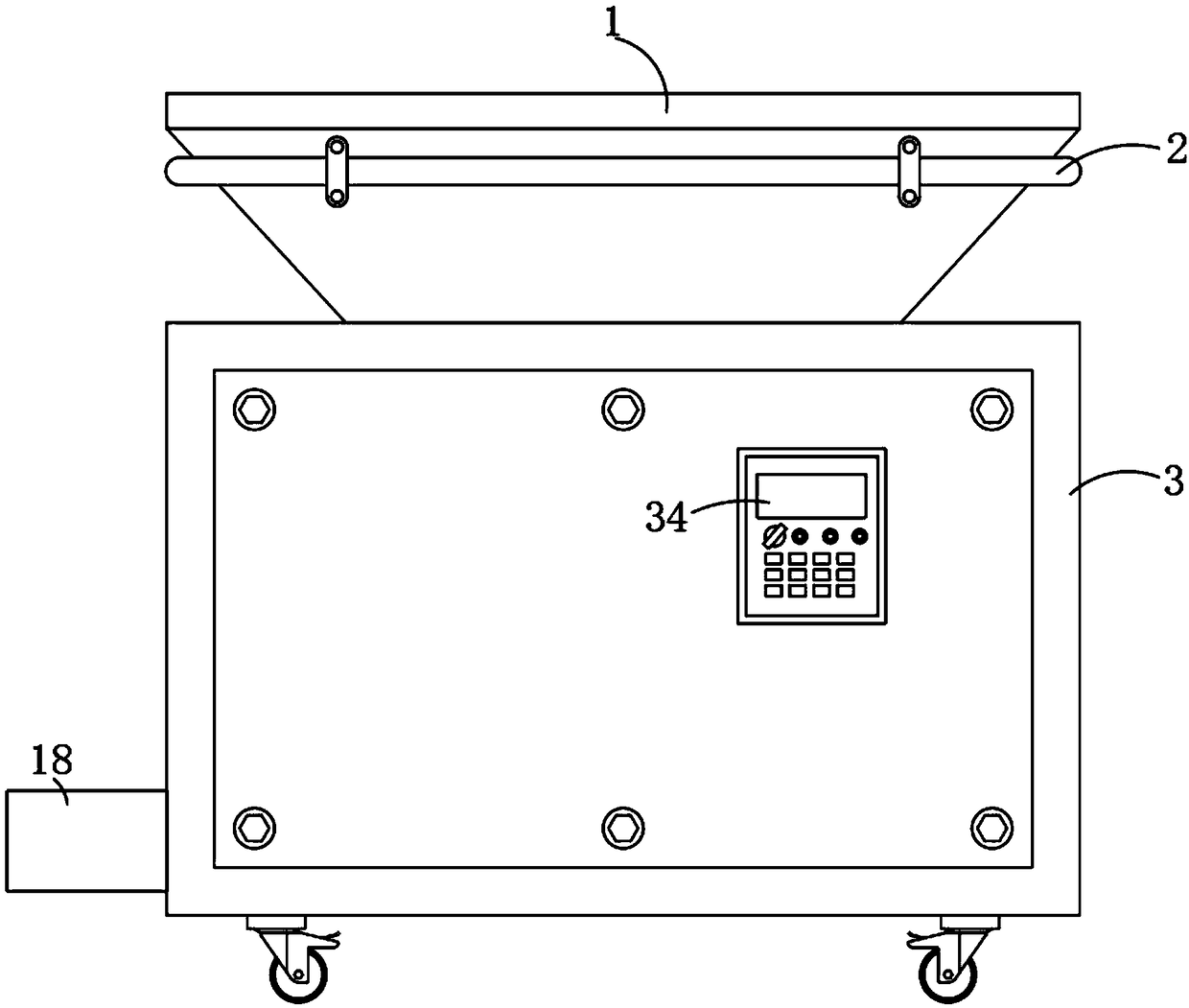

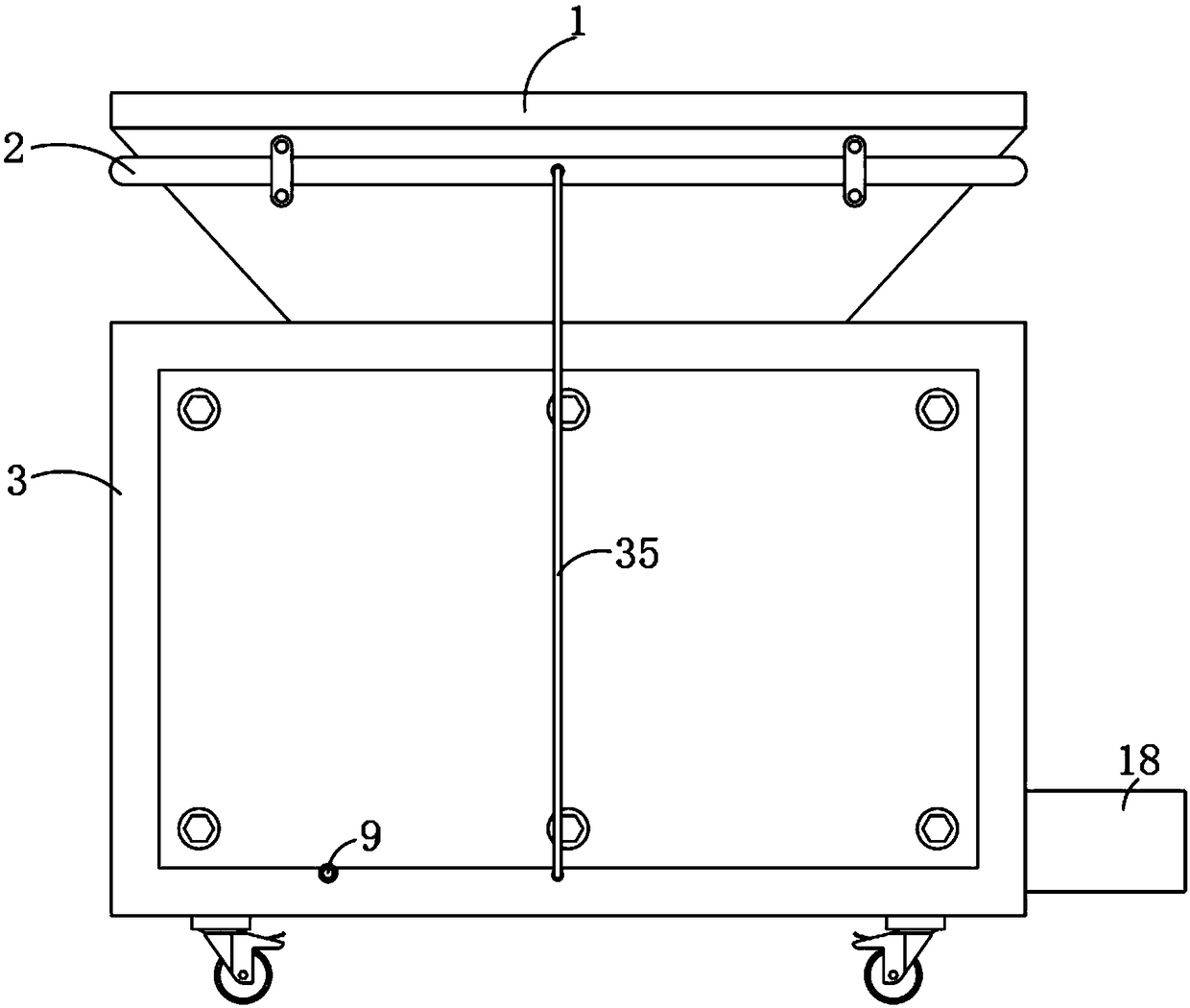

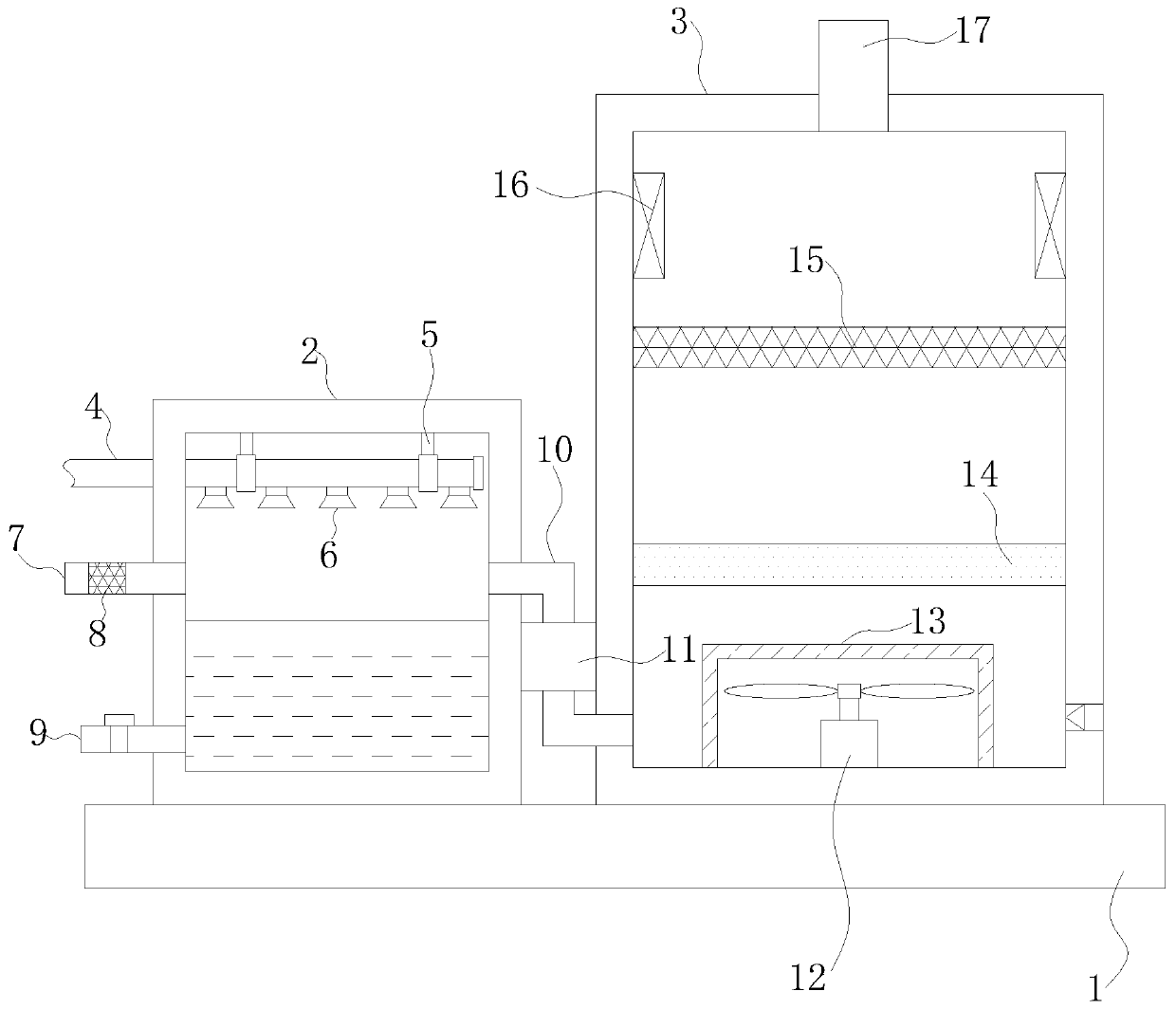

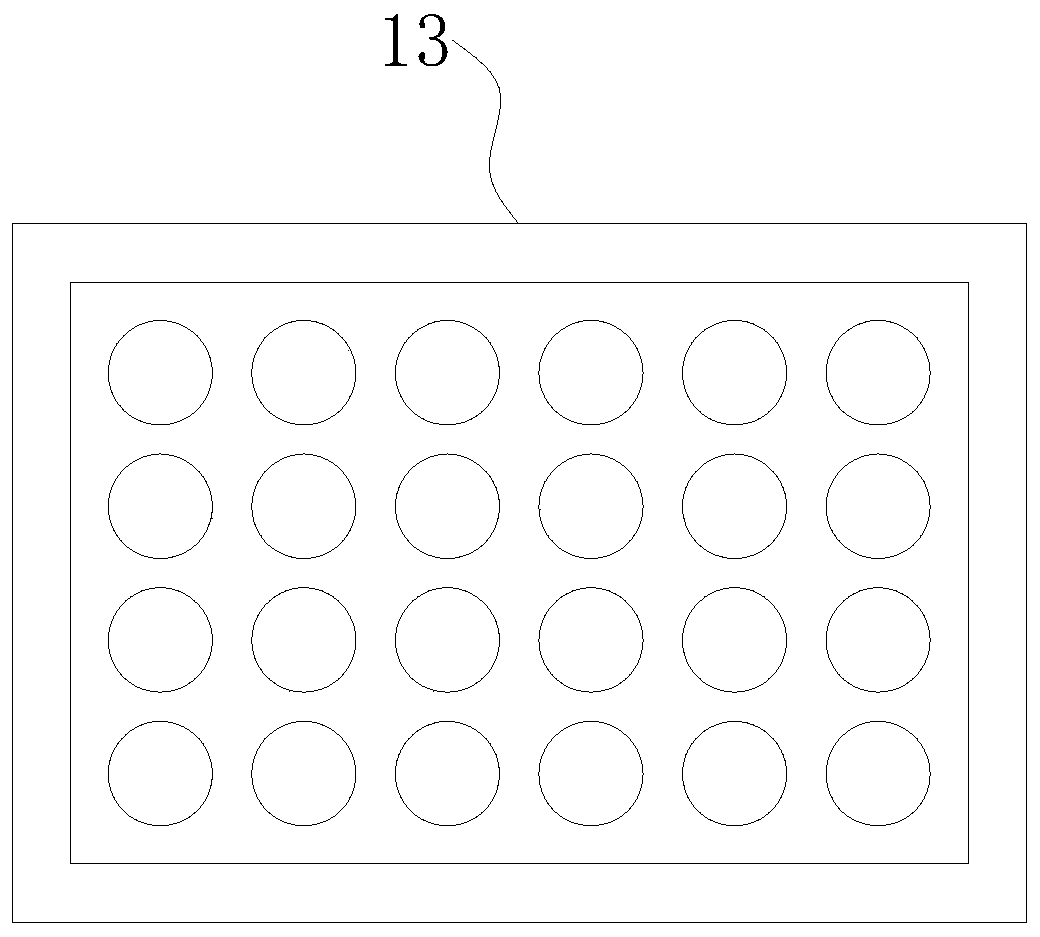

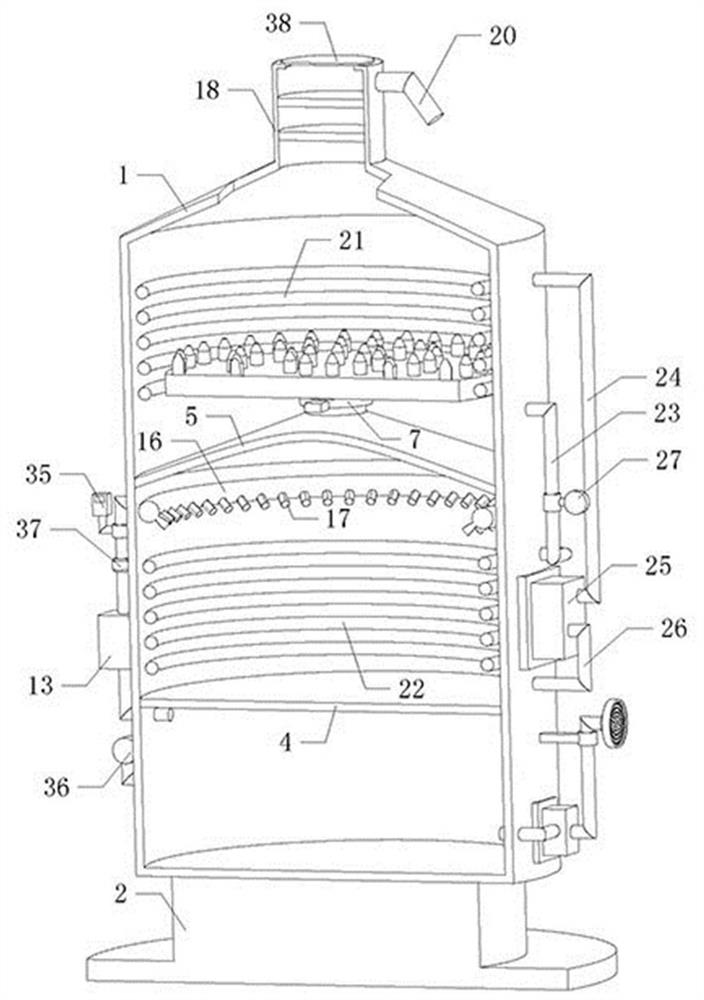

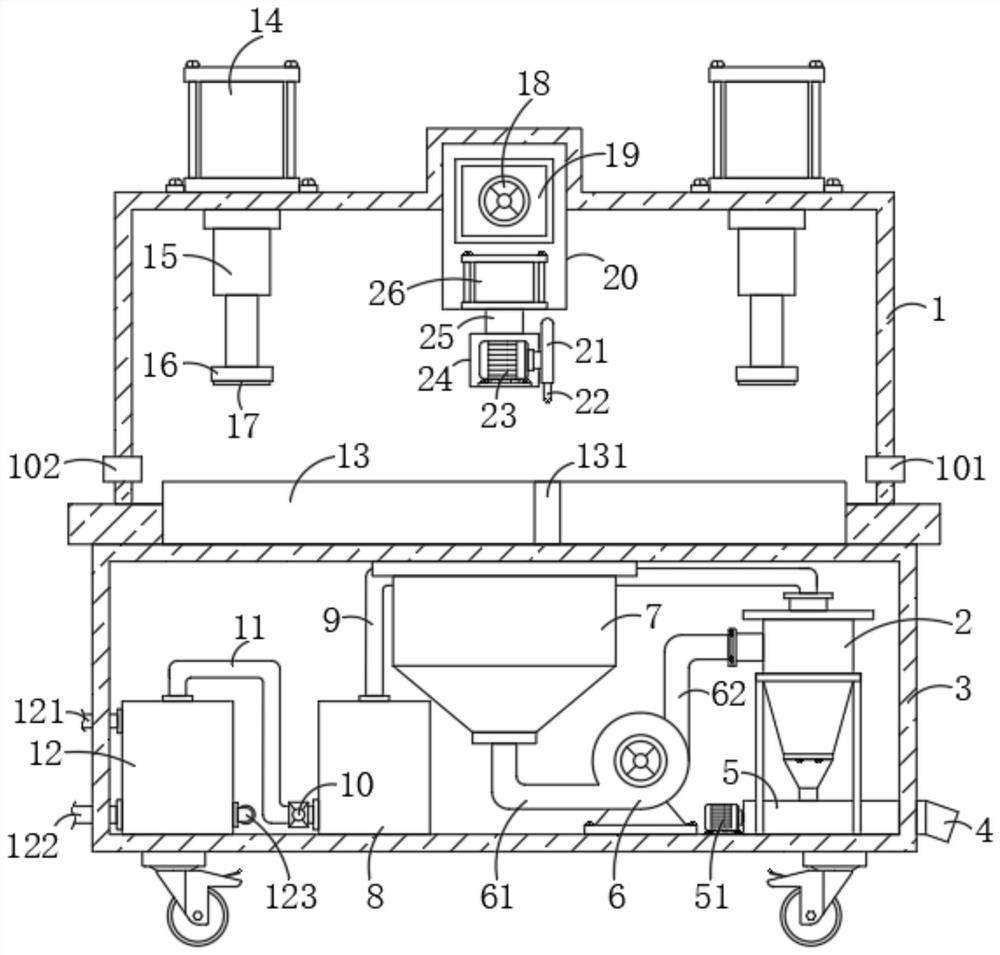

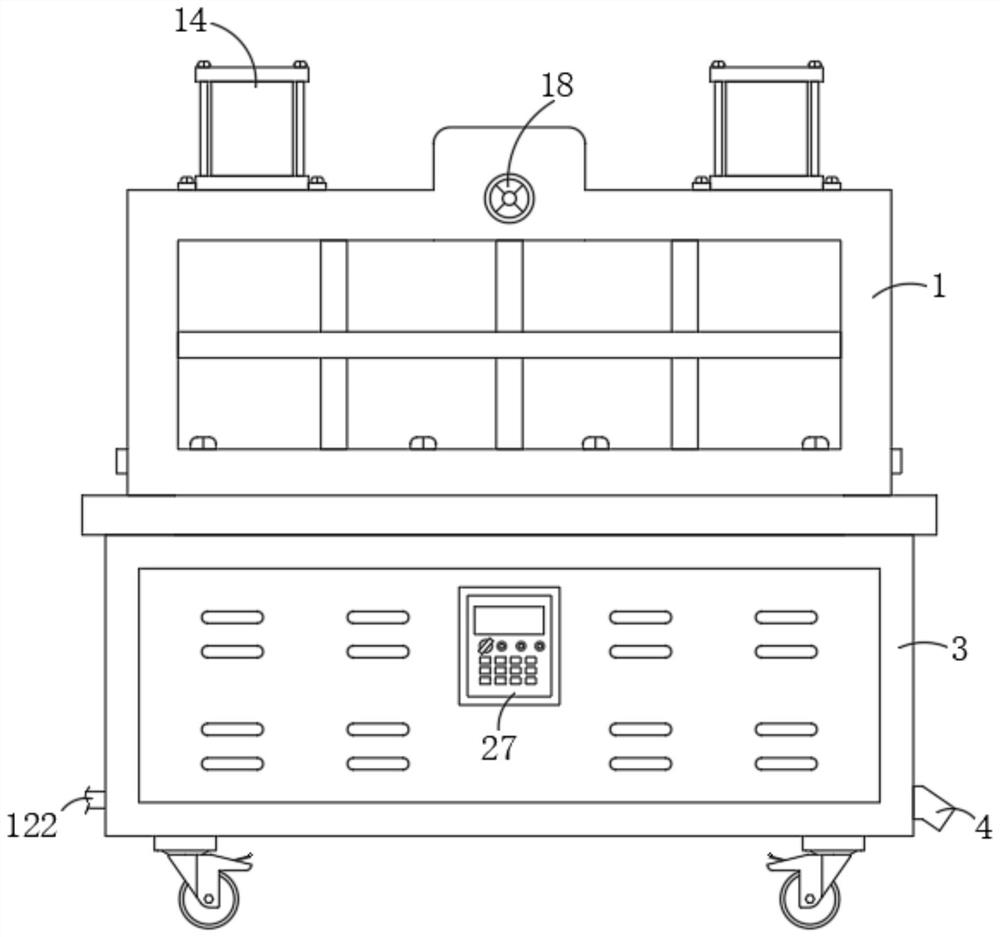

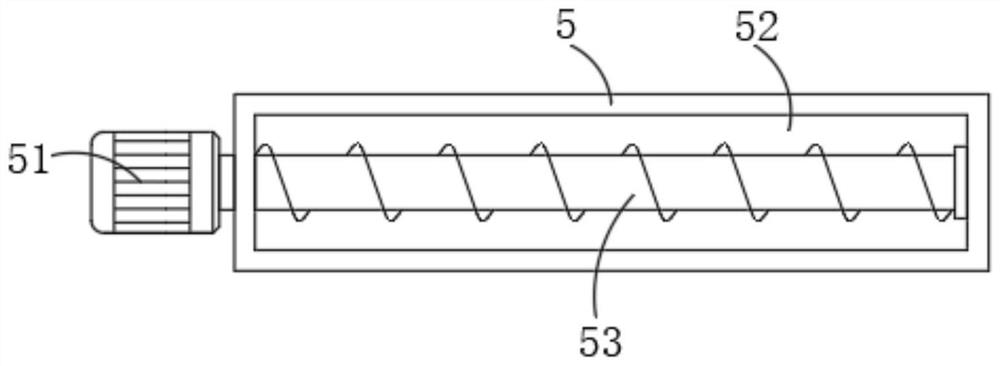

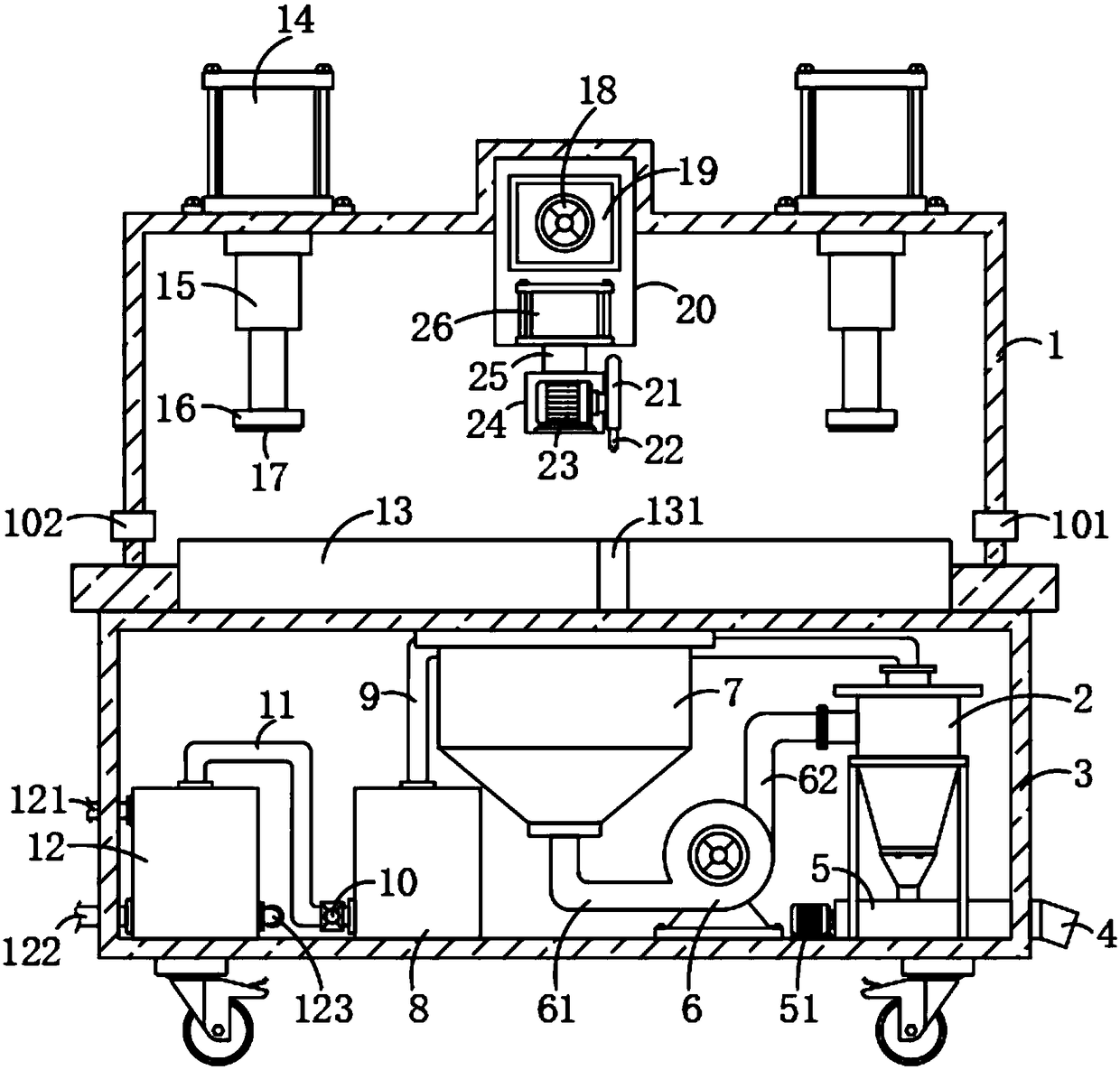

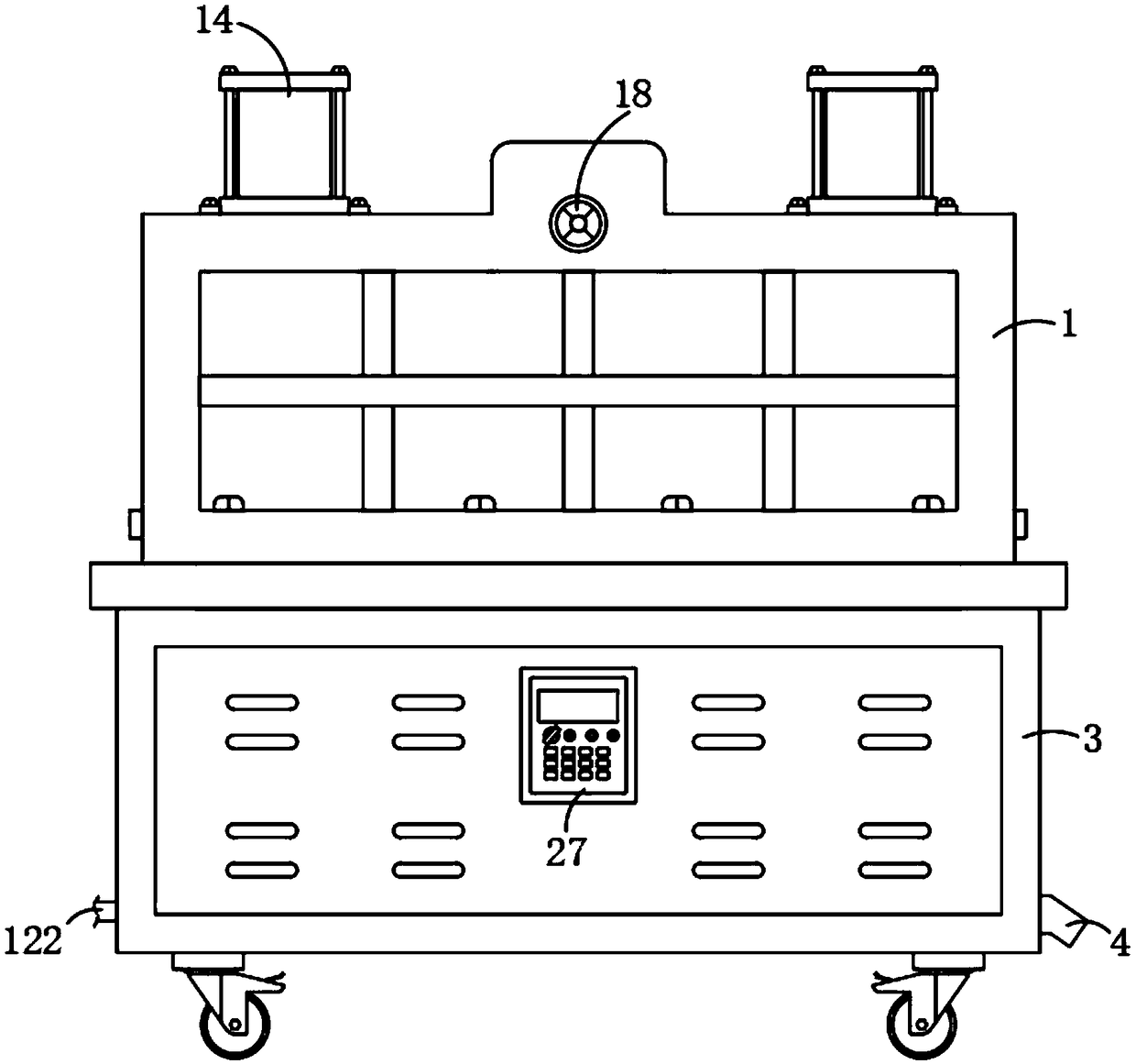

The invention relates to waste gas treatment equipment and method and belongs to the field of environmental protection equipment. The waste gas treatment equipment comprises an activated carbon adsorption box, a spray tower and a circulating water tank, wherein the activated carbon adsorption box and the circulating water tank are both communicated with the spray tower; the activated carbon adsorption box comprises a box body, an adsorption plate, a limiting device, a positioning device and a driving device; the limiting device is mounted in the box body; the adsorption plate is mounted on thelimiting device; the positioning device is in contact with the adsorption plate; the driving device is connected with the adsorption plate; the spray tower comprises a spray tower device, a sprayingdevice and a cyclone device; the spraying device and the cyclone device are both mounted in the spray tower device; the spraying device is positioned above the cyclone device; the circulating water tank comprises a circulating water tank device, a sludge conveying device, a blow-down apparatus and a water supply device; all the sludge conveying device, the blow-down apparatus and the water supplydevice communicate with the circulating water tank device; and both the box body and the sludge conveying device communicate with the spray tower device. The working efficiency is improved, and the waste gas treatment is complete.

Owner:浙江新环环保科技有限公司

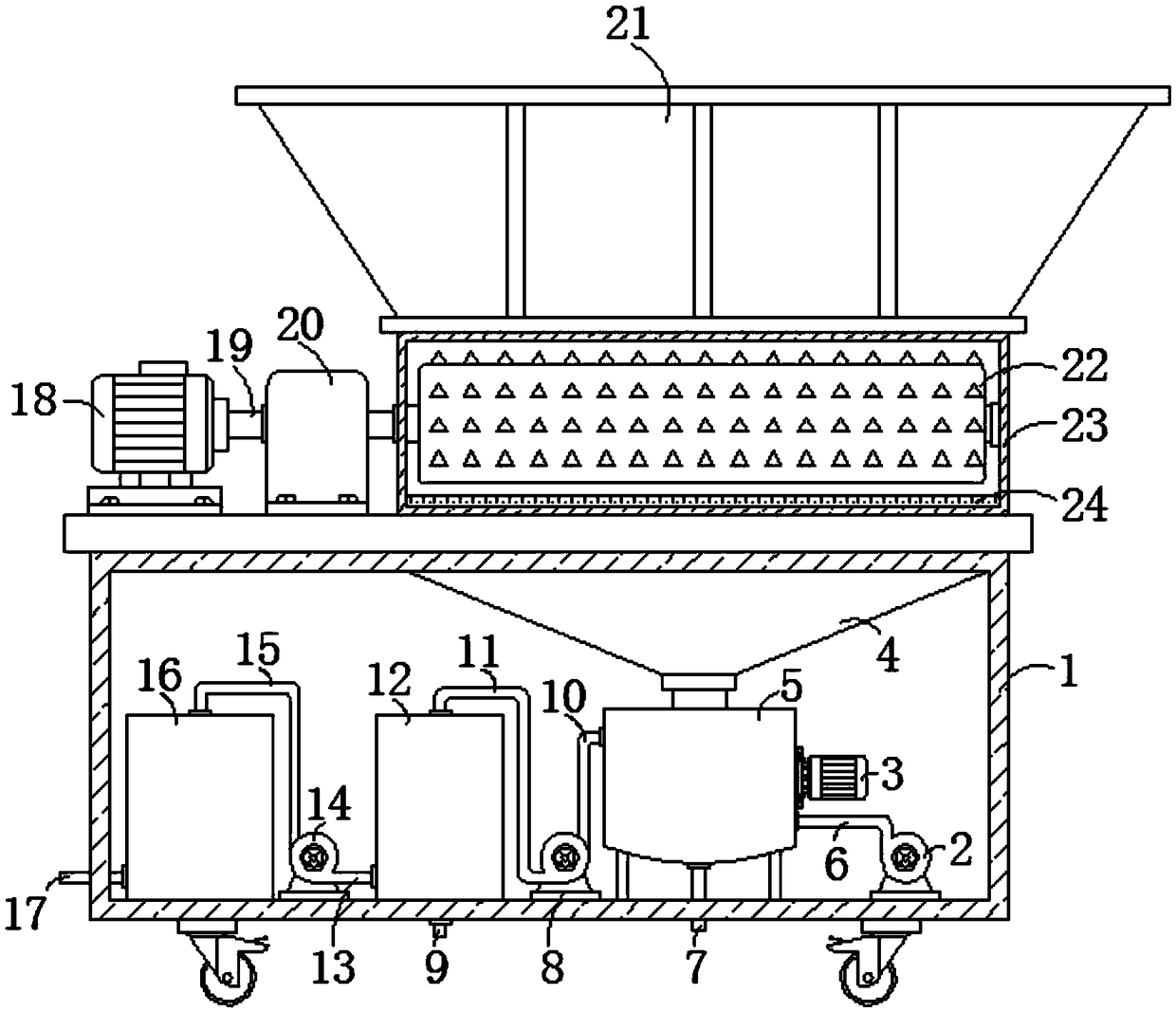

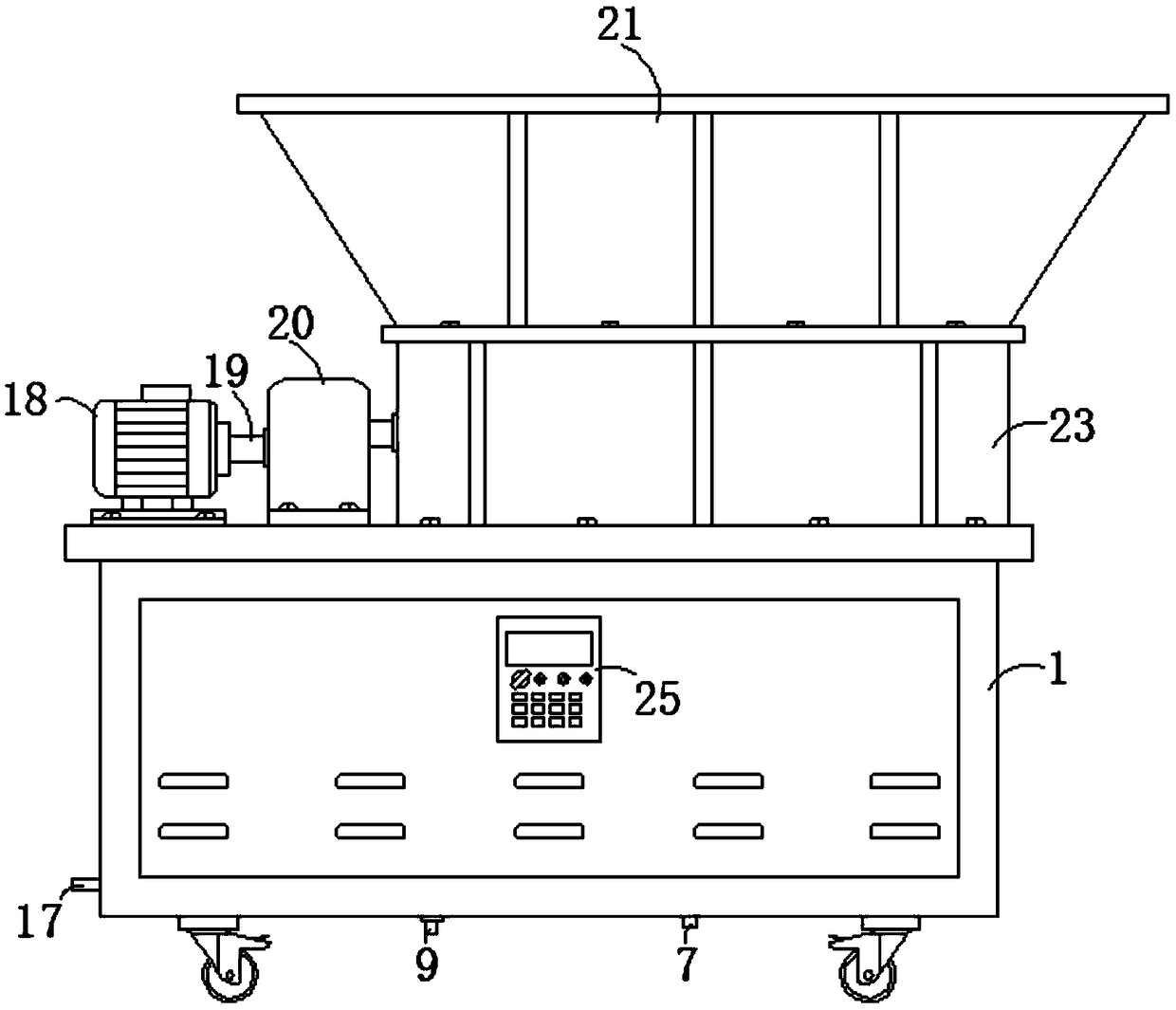

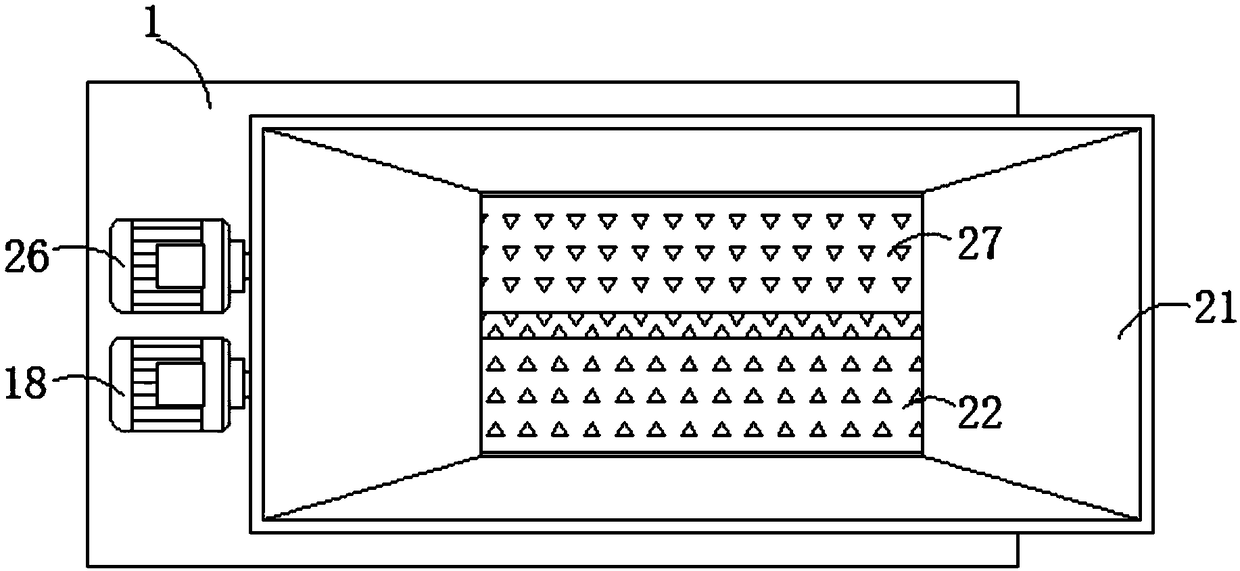

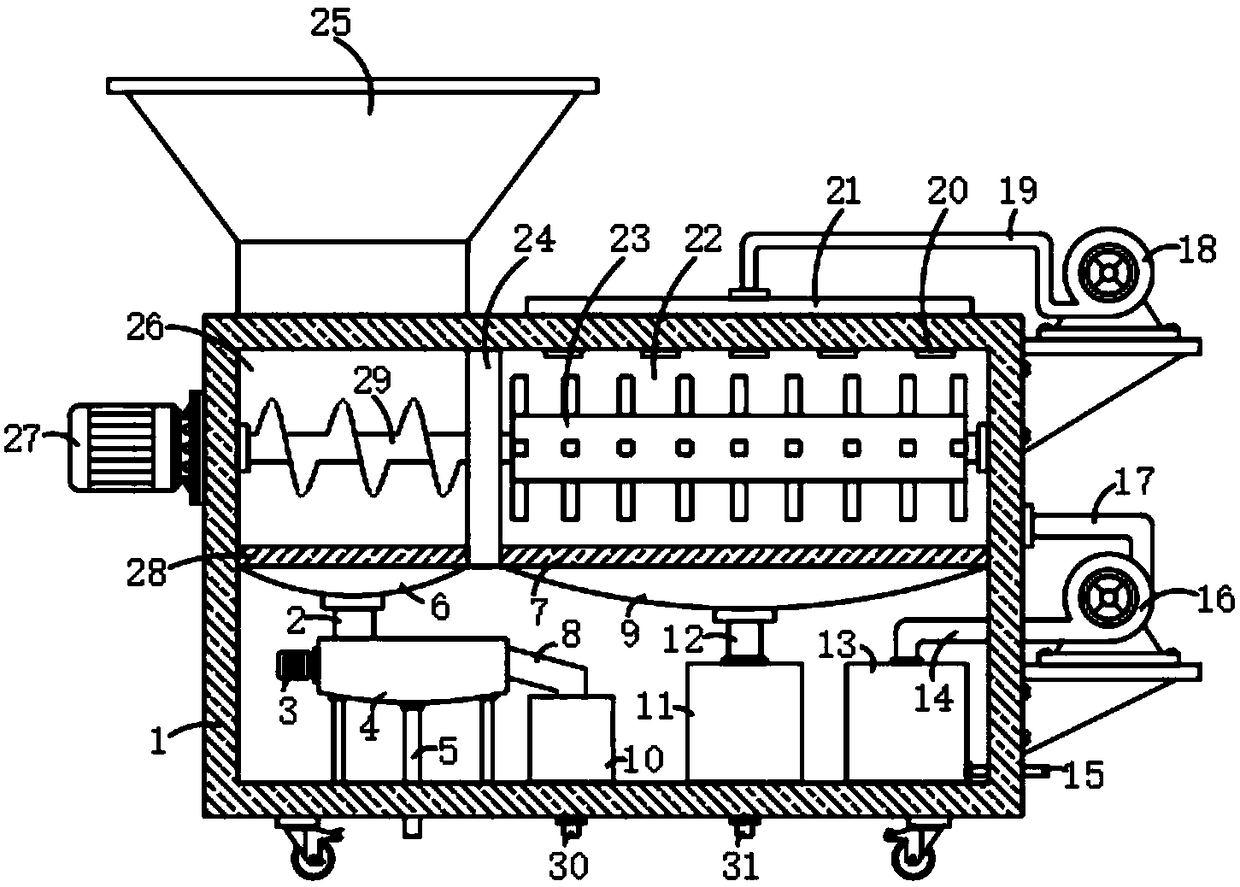

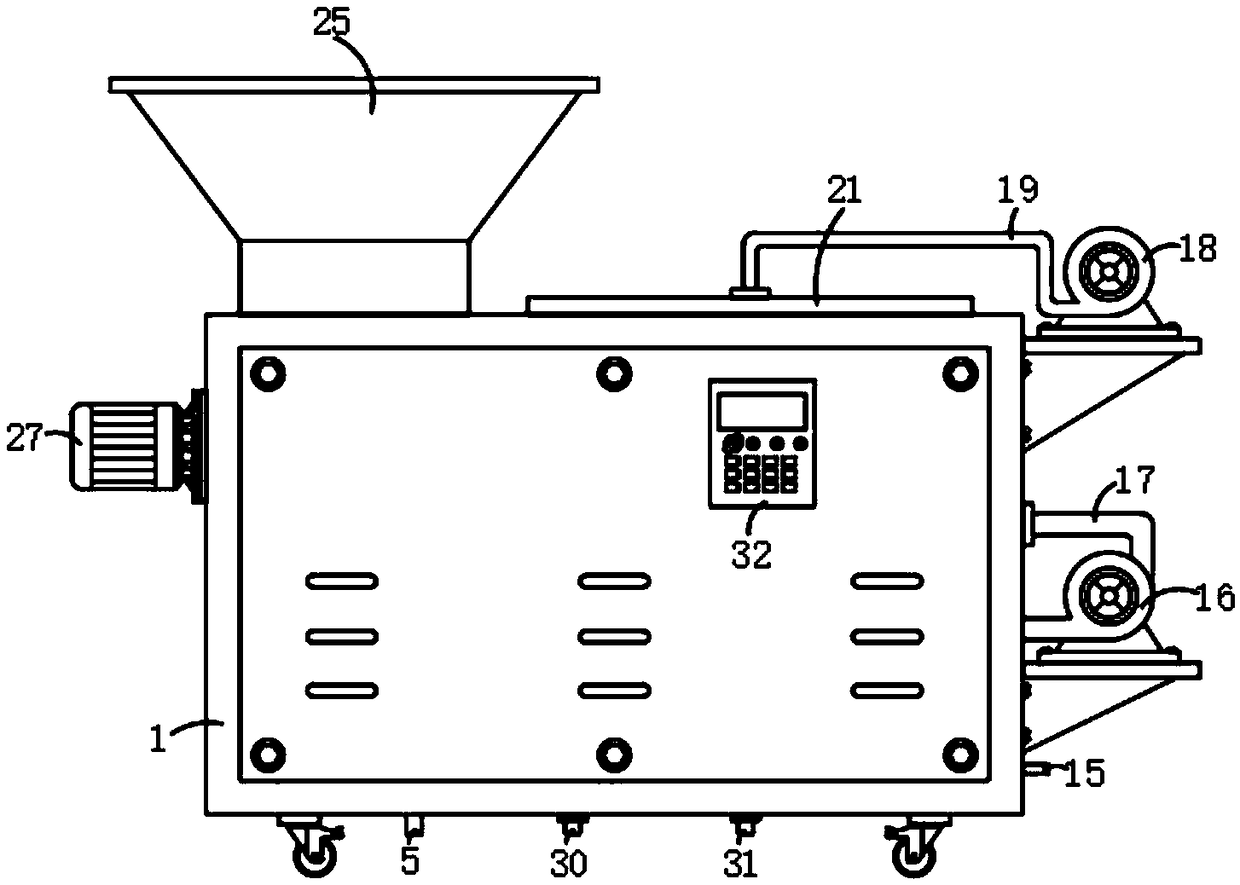

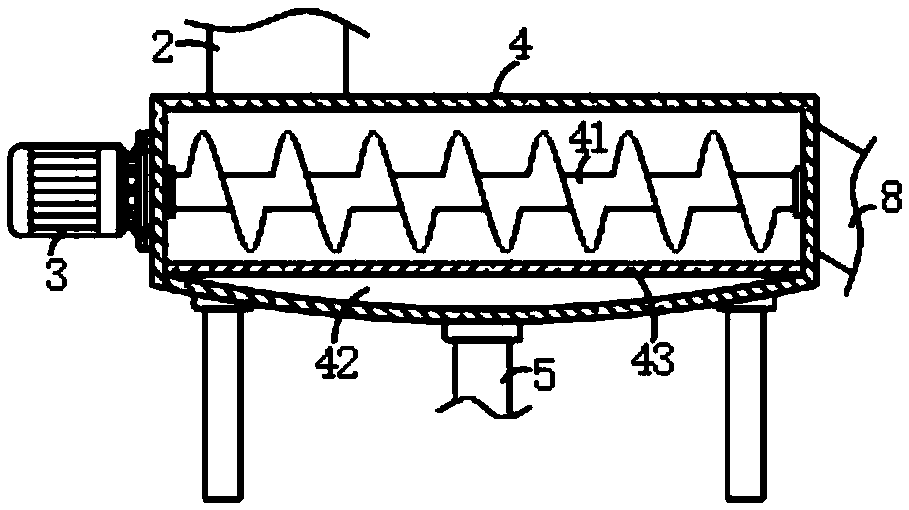

Crushing device for production and processing of organic fertilizers

InactiveCN109092536AIncrease production capacityEasy to storeGas treatmentDispersed particle separationWater resourcesPulp and paper industry

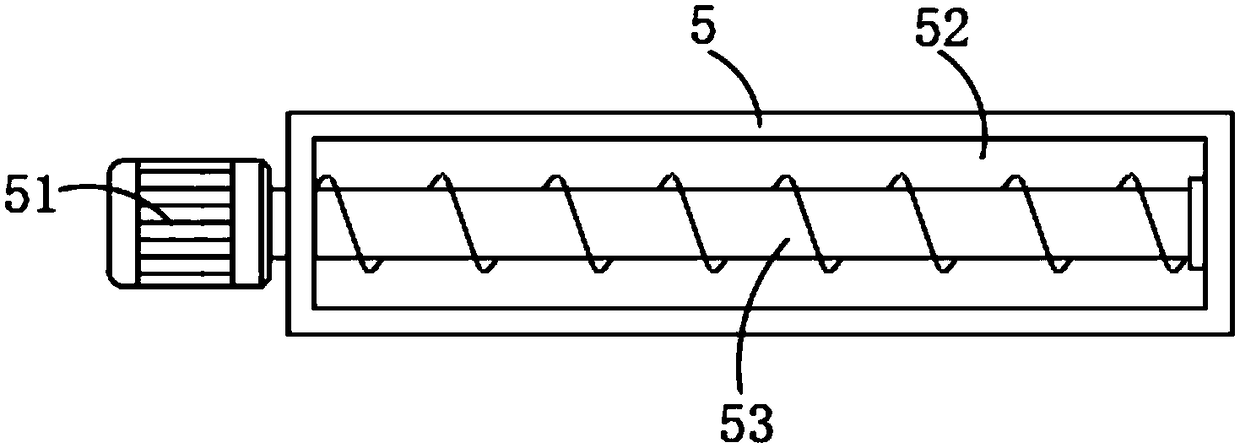

The invention discloses a crushing device for production and processing of organic fertilizers. The crushing device comprises a case. A crushing bin is mounted on one side of the upper surface of thecase, and a collecting groove communicating with the crushing bin is formed in the top end in the case. A drying bin is connected to the position under the collecting groove through a pipeline. A hotair blower is mounted at the side, close to the drying bin, of the interior of the case. A purifying box is fixed to the side, opposite to the hot air blower, of the interior of the case. A hot air pipe is connected between one end of the hot air blower and the bottom of the drying bin. The bottom end of the drying bin is connected with a discharging pipe. According to the crushing device, crushedmaterials can be dried efficiently and evenly, water in the materials is effectively removed, later production and storage of the organic fertilizers are facilitated, meanwhile, recycling of water resources can be achieved, the utilization rate of the water resources is increased, waste of the water resources is avoided, the more energy-saving effect of the crushing device is achieved, in addition, exhaust gas can further be purified, air pollution is prevented, and the more environment-friendly effect of the crushing device is achieved.

Owner:广州顺途信息科技有限公司

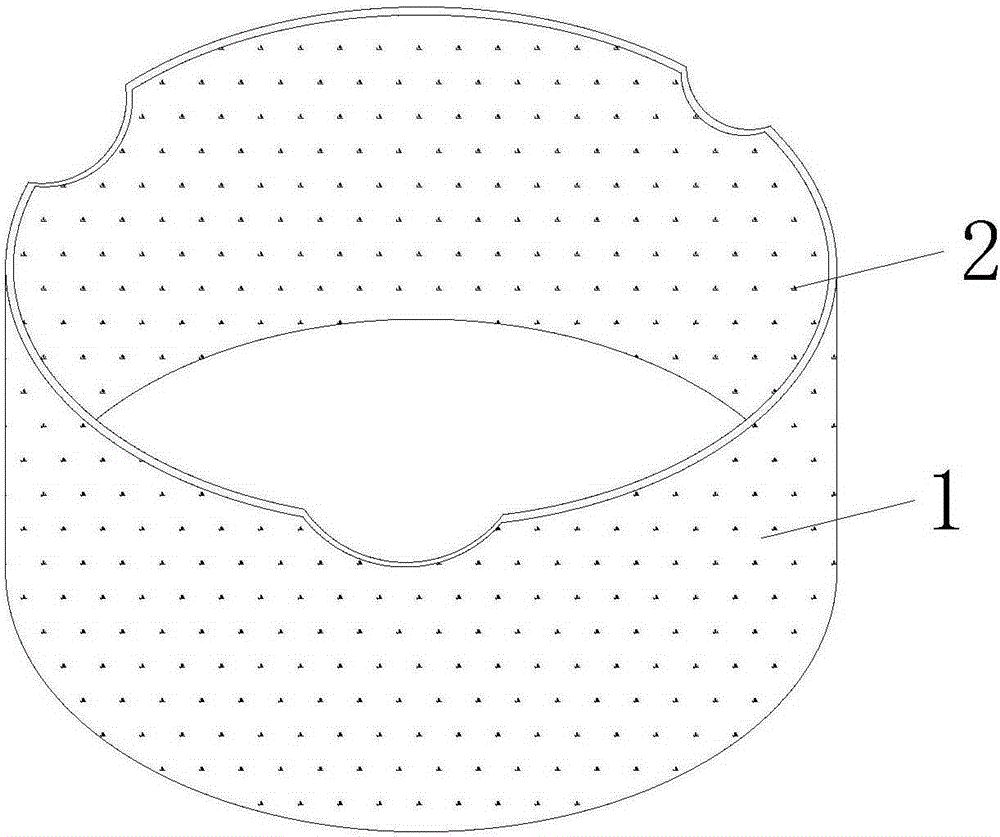

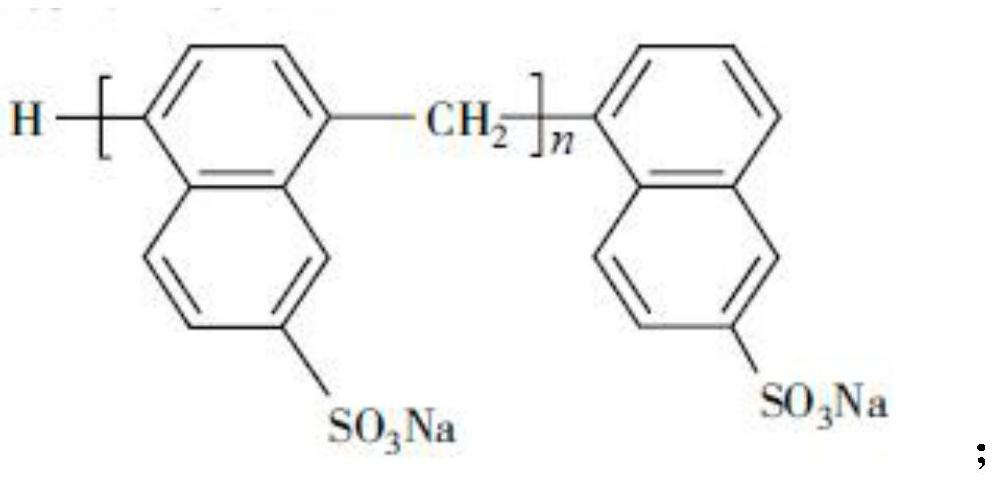

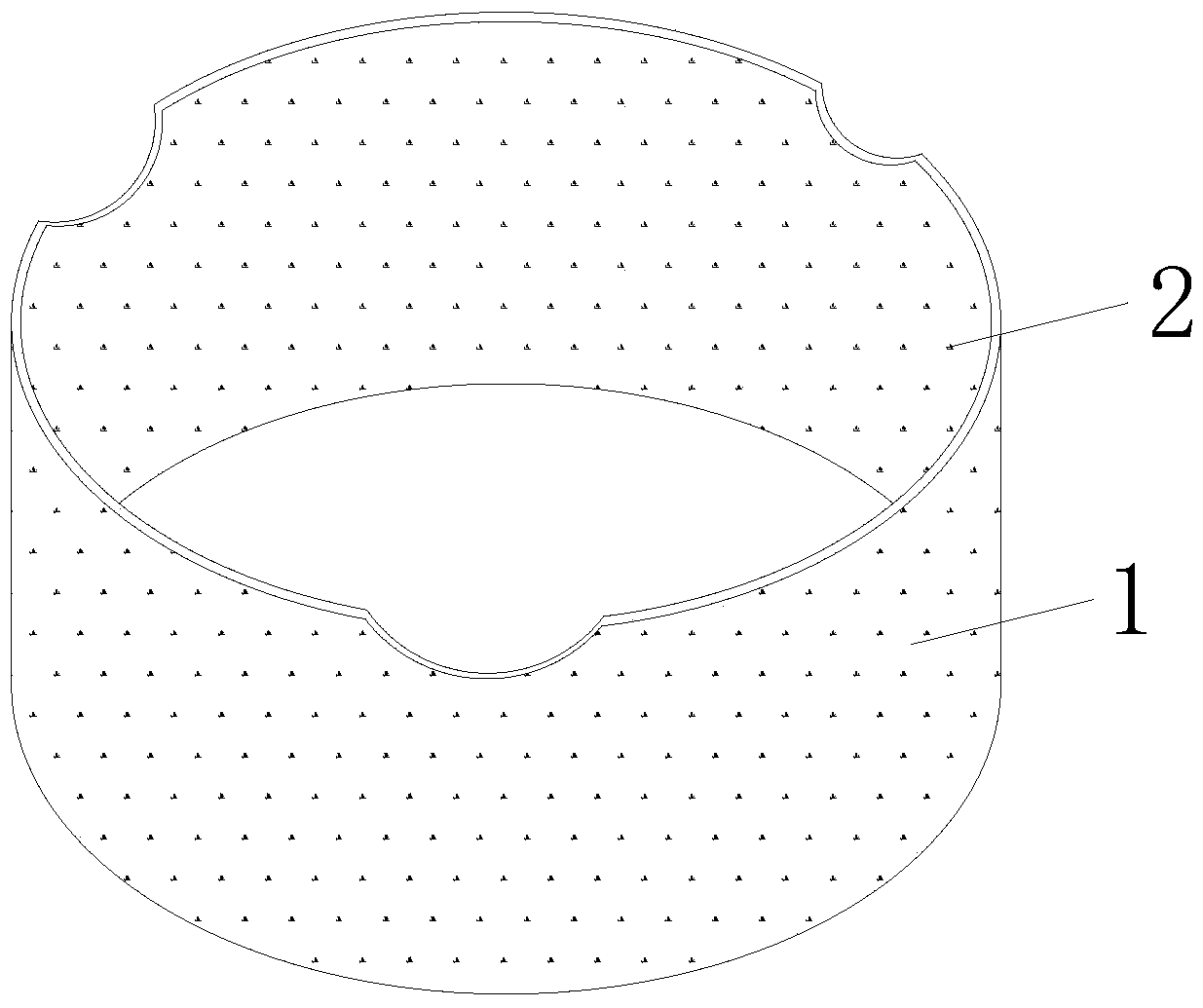

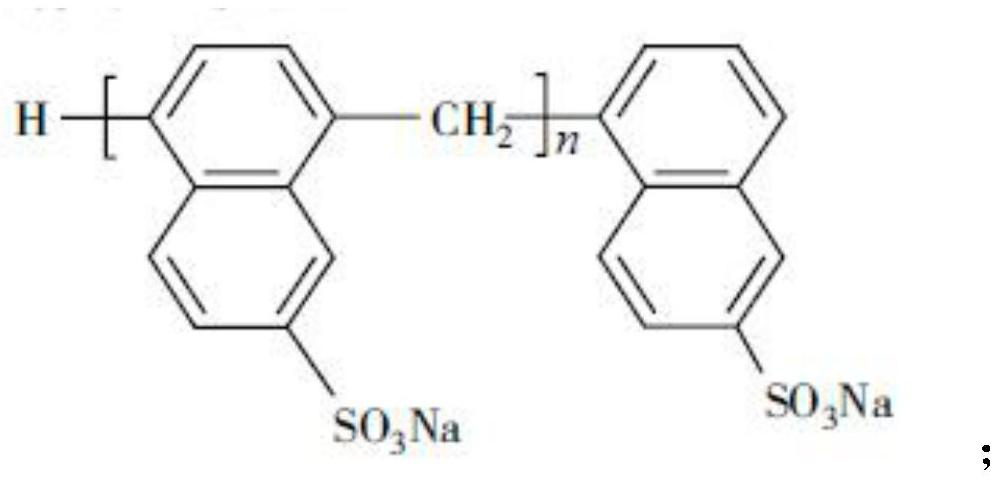

Catalytic ceramic sintered ring for waste gas treatment and preparation method thereof

InactiveCN105214706ATo achieve the purpose of purifying exhaust gasImprove productivityDispersed particle separationRaney catalystsActivated carbonZinc

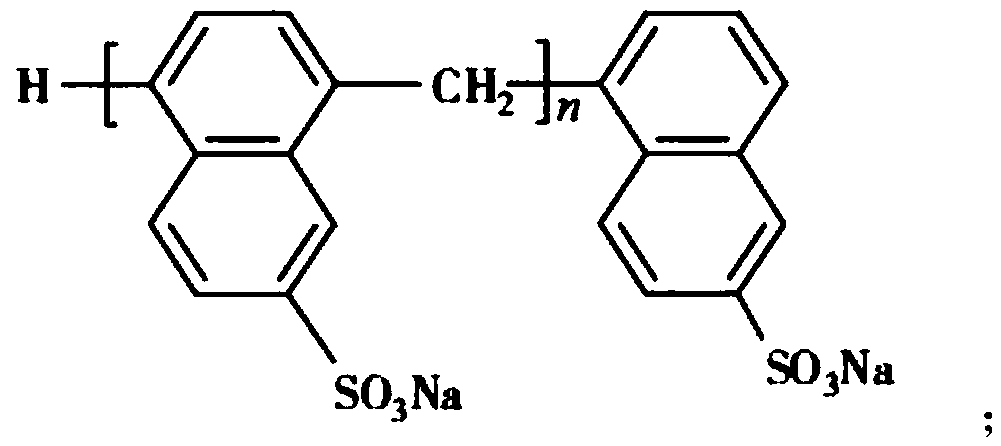

The invention belongs to the technical field of waste gas purification materials, and particularly relates to a catalytic ceramic sintered ring for waste gas treatment and a preparation method thereof. The catalytic ceramic sintered ring is prepared from the following components in percentage by weight: 2 to 6 percent of aluminum oxide, 3 to 4 percent of titanium dioxide, 3 to 5 percent of iron oxide, 3 to 4 percent of zirconium oxide, 4 to 5 percent of lanthanum oxide, 3 to 6 percent of cerium oxide, 2 to 4 percent of praseodymium oxide, 4 to 5 percent of zinc oxide, 30 to 35 percent of activated carbon powder and 40 to 45 percent of silicon carbide. The catalytic ceramic sintered ring for the waste gas treatment, provided by the invention, is high in catalytic reaction efficiency and remarkable in waste gas purification efficiency.

Owner:HANGZHOU ZHENGQING ENVIRONMENTAL PROTECTION SCI & TECH

Environment-friendly waste gas treatment equipment

ActiveCN106215658AConserve waterReduce impactCombination devicesGas treatmentIonEnvironmental resistance

The invention discloses environment-friendly waste gas treatment equipment. The environment-friendly waste gas treatment equipment comprises a rectifier, a reaction cavity, a purification tower, an ultraviolet reaction tower, an electrostatic dust collector, an exhaust gear and a waste gas detection system which are all communicated in sequence, the purification tower comprises a purification device and a filter device, and the filter device is located above the purification device; the purification is communicated with the ultraviolet reaction tower through a second circulation pipe, and one side of the reaction cavity is communicated with a low-temperature ion generator; a bent plate is arranged at the bottom of the purification device, flushing pipes are connected to two sides of the purification device, venturi pipes are mounted on the corresponding flushing pipes, multiple sets of ultraviolet lamps are arranged in the ultraviolet reaction tower, and a filter is arranged at the bottom of the ultraviolet reaction tower; the electrostatic dust collector comprises a dust collection plate and a corona pin; the exhaust gear comprises an exhaust manifold and multiple exhaust branches, and the waste gas detection system comprises a controller, a gas sensor and an alarm. By the arrangement, problems that existing waste gas treatment is poor in purification effect and incomplete in purification and service life of the equipment is short can be solved.

Owner:深圳市东荣环保科技有限公司

Efficient bag-type air dust remover

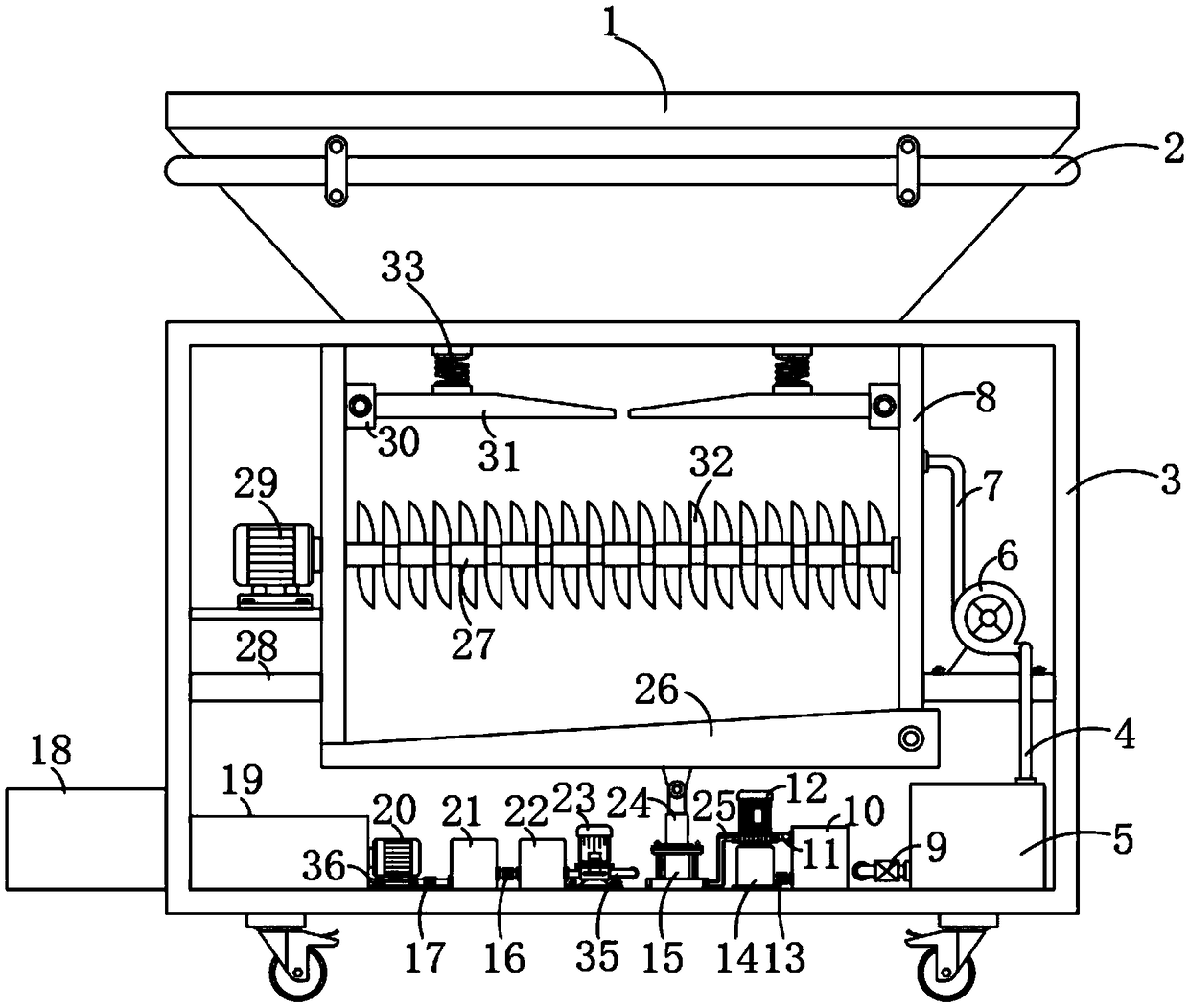

InactiveCN108043132APrevent filter damageClean up in timeDispersed particle filtrationLap jointPulley

The invention discloses an efficient bag-type air dust remover. The efficient bag-type air dust remover comprises a box body and an air inlet pipe, the air inlet pipe is installed at the top of the left side of the box body, bottom pillars are installed at the four corners of the bottom of the box body, the outer wall of the bag body is connected with the inner wall of a top plate, a motor wheel is connected with idler wheels through a belt, multiple top rods are installed on the outer walls of the idler wheels, first springs are installed in inner cavities of the top rods, connecting rods areinstalled at the tops of the first springs, and pulleys are installed at the tops of the connecting rods, and are in lap joint with the outer walls of the right sides of filters. By means of the efficient bag-type air dust remover, through an air pump which is installed on the inner wall of the top of the box body, it is also prevented that the filters are damaged when the filters are fiercely struck by the idler wheels; through a waste residue opening which is formed in the bottom of the box body, waste residues filtered out by the filters can fall down along the waste residue opening, the purpose of timely cleaning away the residues is achieved, and it is prevented that the filtering effect gets poor when too many waste residues are accumulated inside the box body.

Owner:陈卫

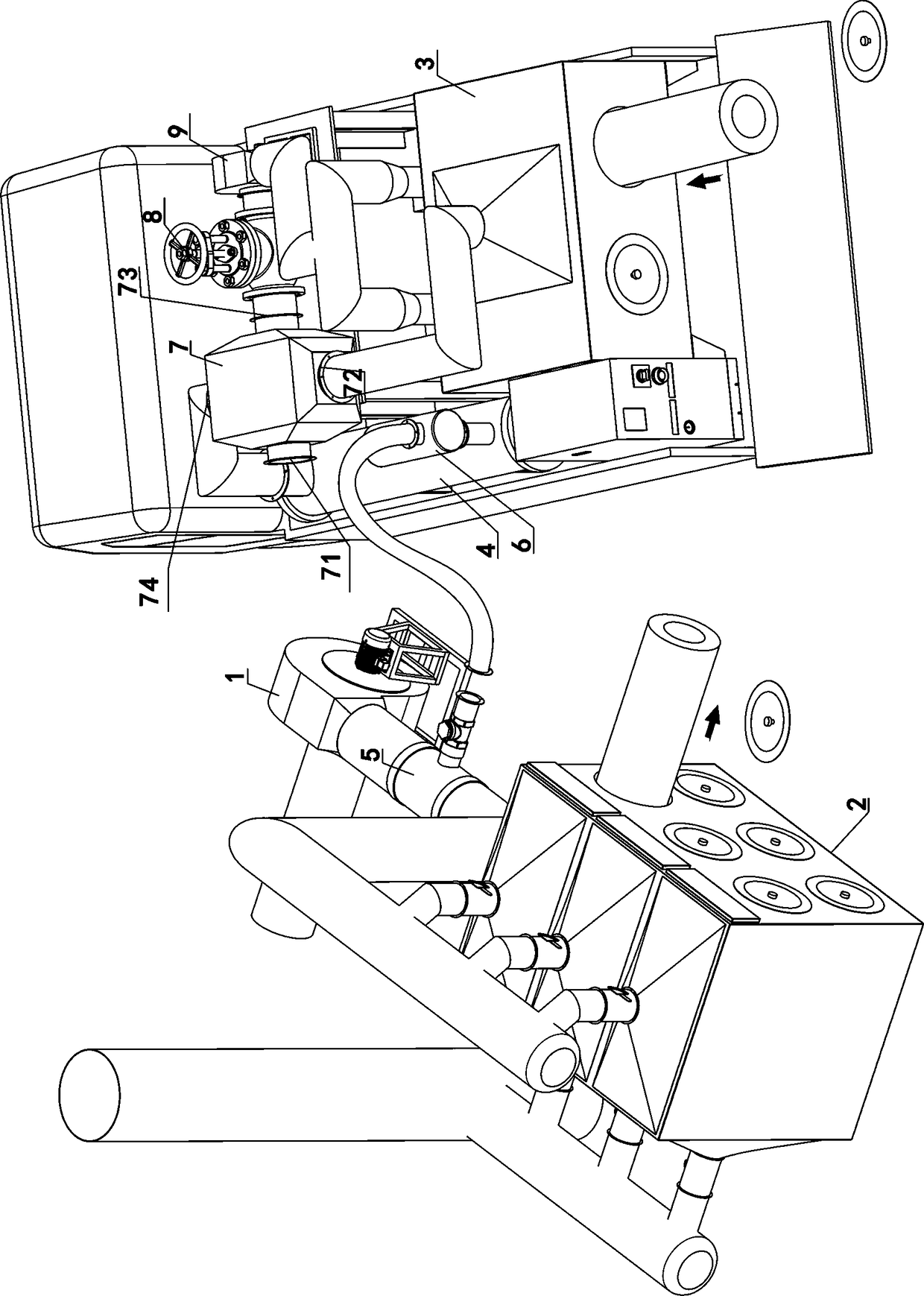

Multi-occasional application waste gas purifying device for environmental protection engineering

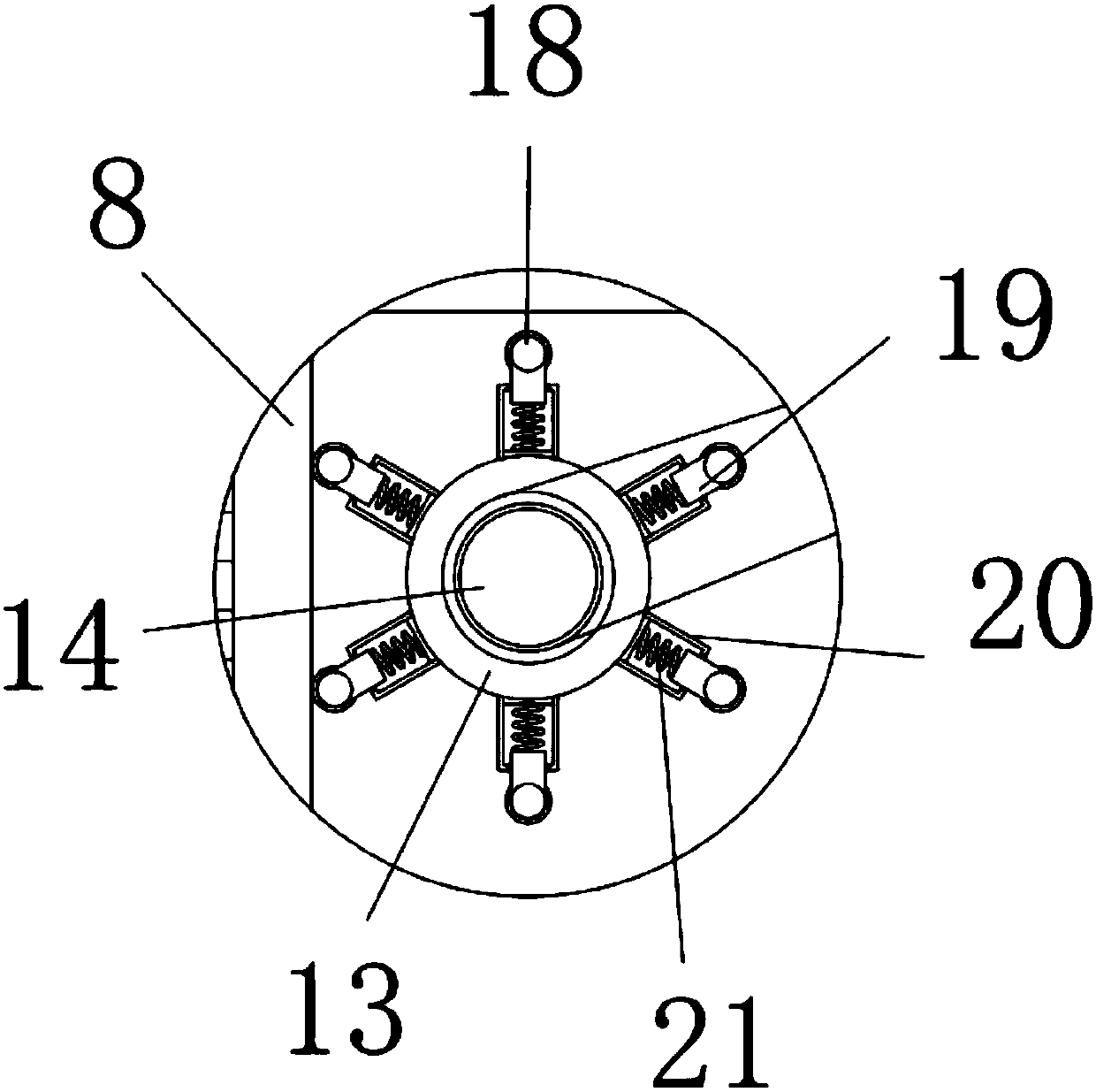

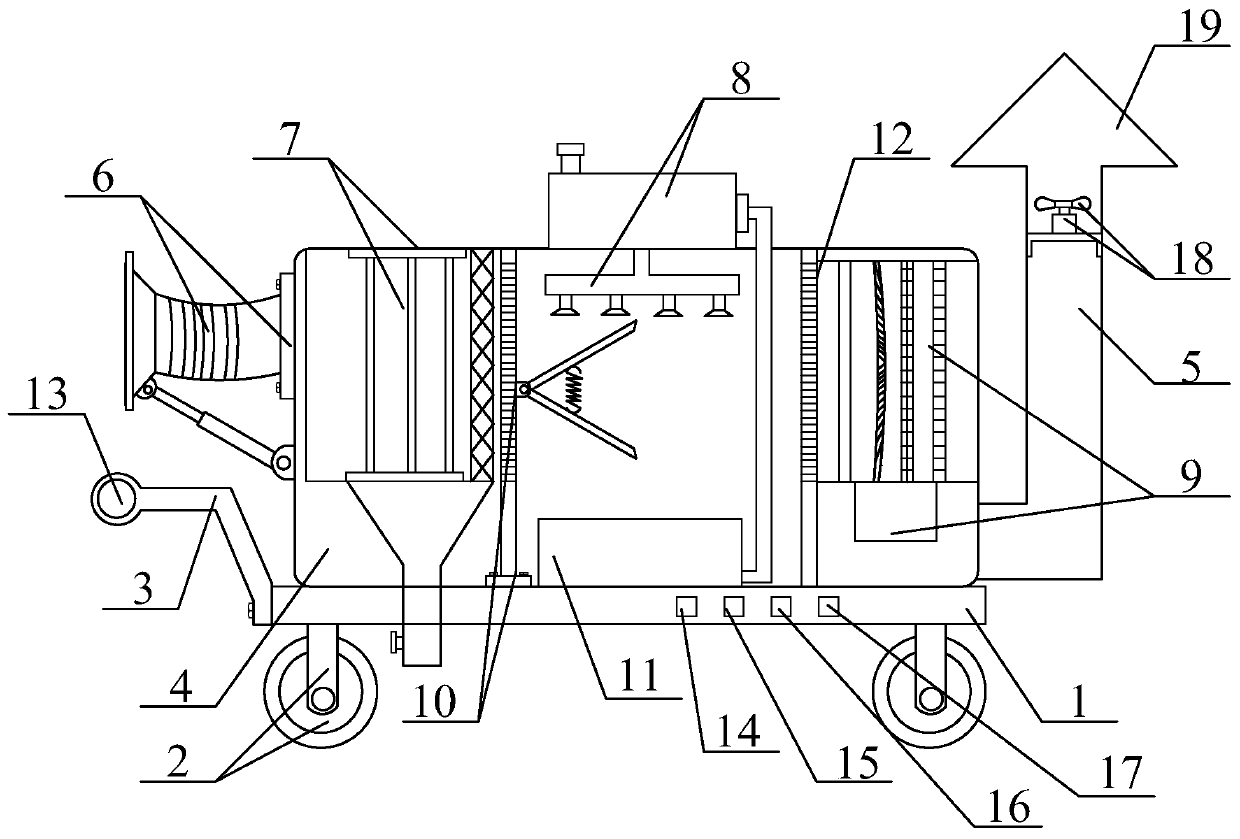

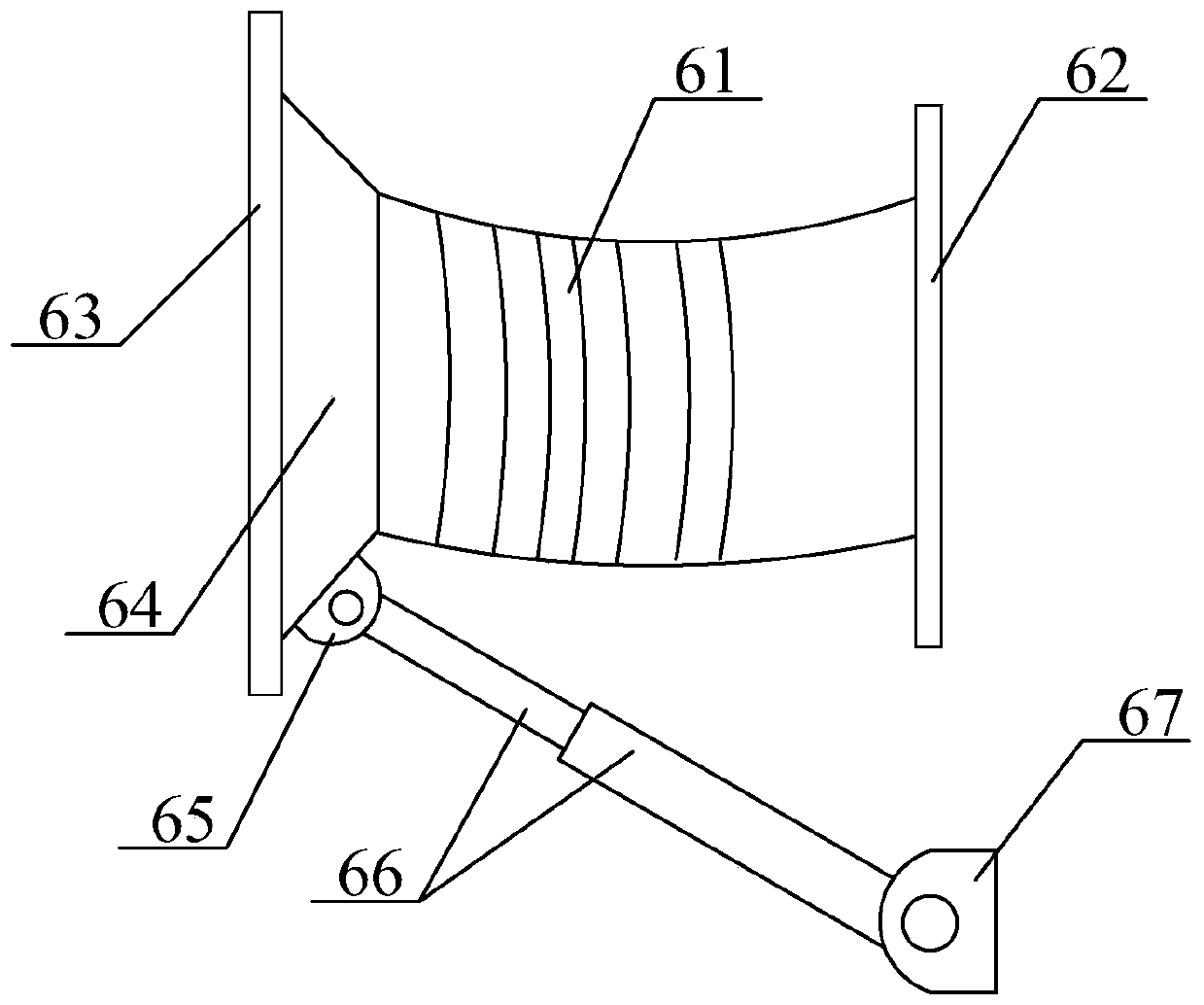

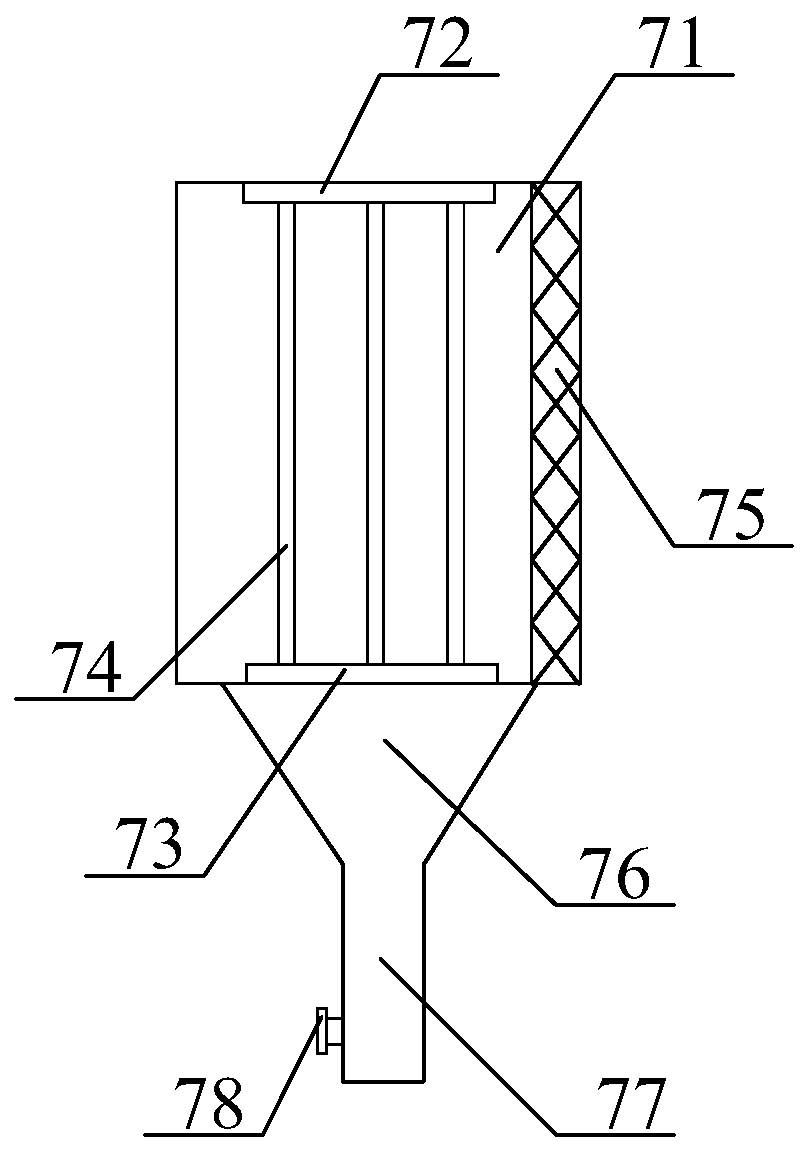

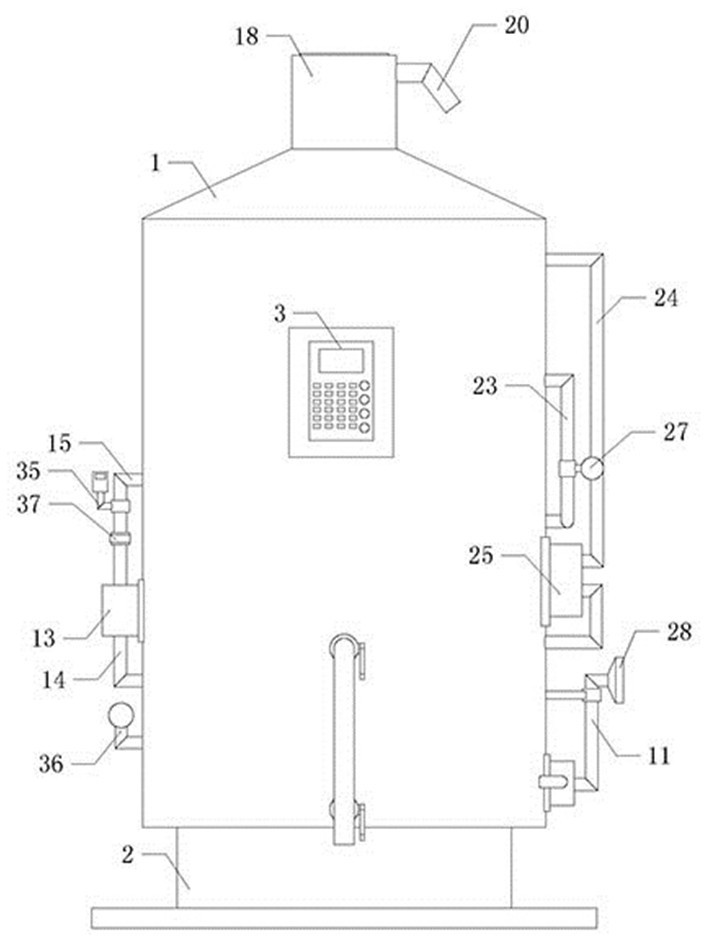

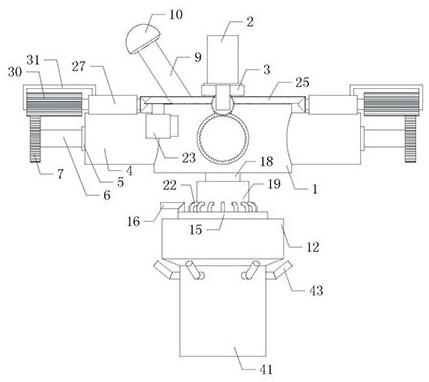

The invention provides a multi-occasional application waste gas purifying device for environmental protection engineering. The waste gas purifying device comprises a moving tray, moving roller wheels,a traction rod, a purifying tank, an exhaust chimney tube, a conveniently-connected adjustable gas inlet bellows structure, an electrostatic waste gas dust-removing box structure, a circulatable waste gas neutralizing and spraying tank structure, a waste gas purifying barrel structure, a flow-guiding partition board structure, a waste liquid recycling tank, a main partition board, a traction hole, a suction connection control switch, an electrostatic dust removal control switch, a spraying circulation control switch, an exhaust control switch, an exhaust fan and a protective hood. Through thearrangement of a waste gas inlet bellows, a first connecting flange plate, a second connecting flange plate, a gas inlet hood, a first connecting lug plate, an angle adjusting hydraulic cylinder anda second connecting lug plate, rotating adjustment of the second connecting flange plate through the angle adjusting hydraulic cylinder according to different using occasions is facilitated, and connection with a waste gas emitting port is facilitated.

Owner:周粉粉

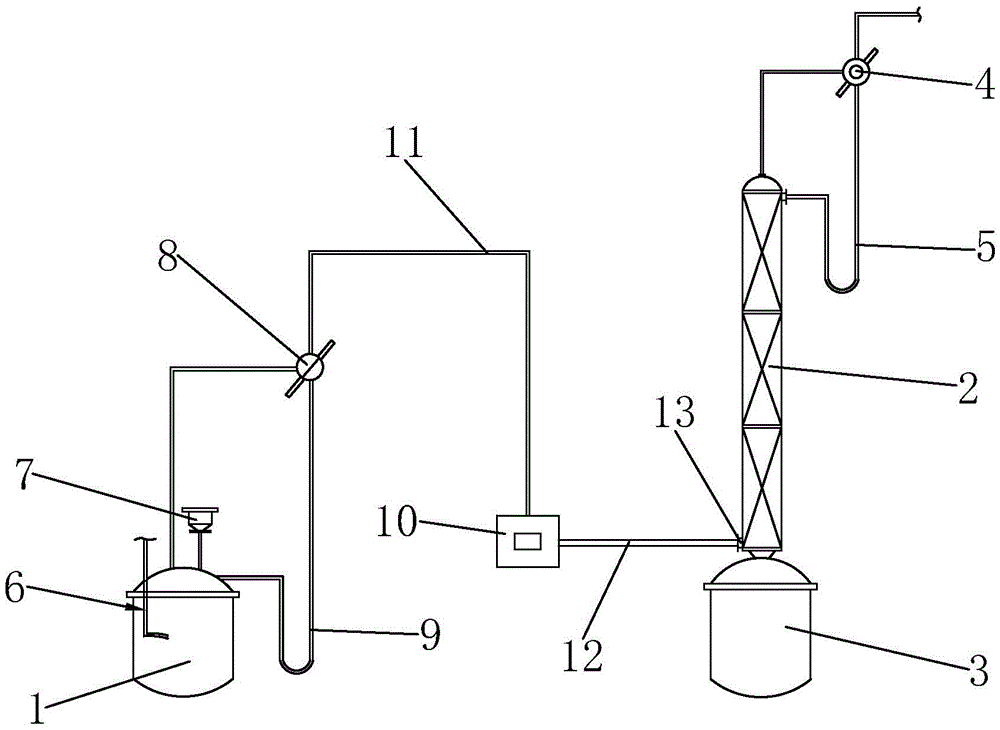

Adsorption desorption condensation recovery method for exhausting activated carbon and device thereof

InactiveCN109012014ARich sourcesIn economic interestGas treatmentDispersed particle separationActivated carbonRecovery method

The invention discloses an adsorption desorption condensation recovery method for exhausting activated carbon and a device thereof. The method comprises: introducing production exhaust gas into activated carbon adsorption devices of several independent adsorption zones through a blower fan, and discharging the exhaust gas to the environment after being absorbed by the activated carbon, transferring the adsorbed saturated activated carbon from the activated carbon adsorption device to an activated carbon desorption device, performing desorption on exhaust gas from the activated carbon through aheat medium, reinstalling the desorbed activated carbon to the activated carbon adsorption device, and introducing the exhaust gas to a condenser for cooling and recycling. The method has the advantages of high efficiency, environmental protection, low operating cost; the device comprises a first blower fan, an activated carbon adsorption device connected to the first blower fan through a three-way pipe, the mobile activated carbon desorption device and a condenser, an air inlet of the condenser is connected to an air outlet of the activated carbon desorption device through a pipeline, and anexhaust port is connected to the three-way pipe which is connected between the blower fan and the activated carbon adsorption device. The device has a simple structure and stable operation, and is adapted to the requirement of different enterprises.

Owner:佛山市墺林环保科技有限公司

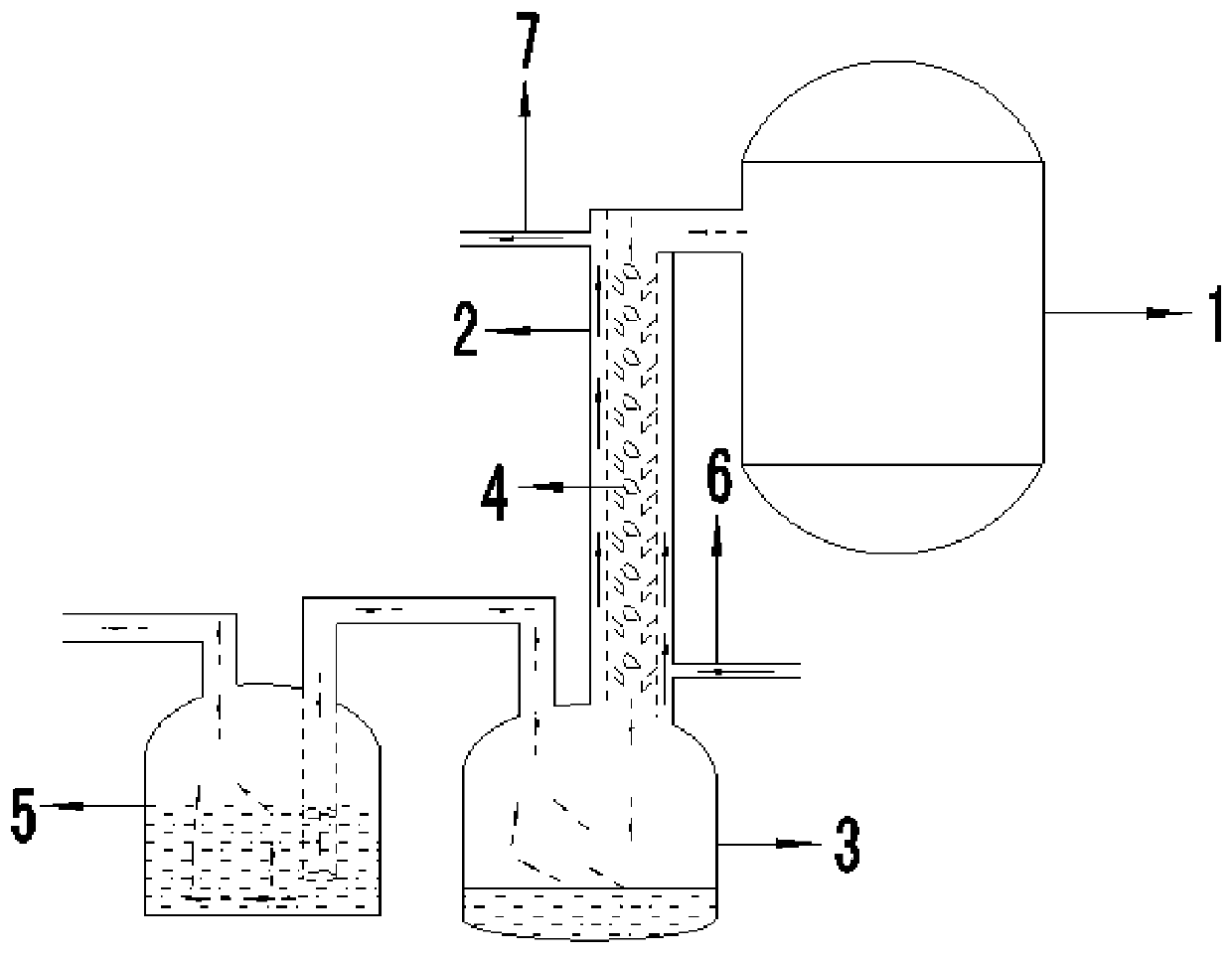

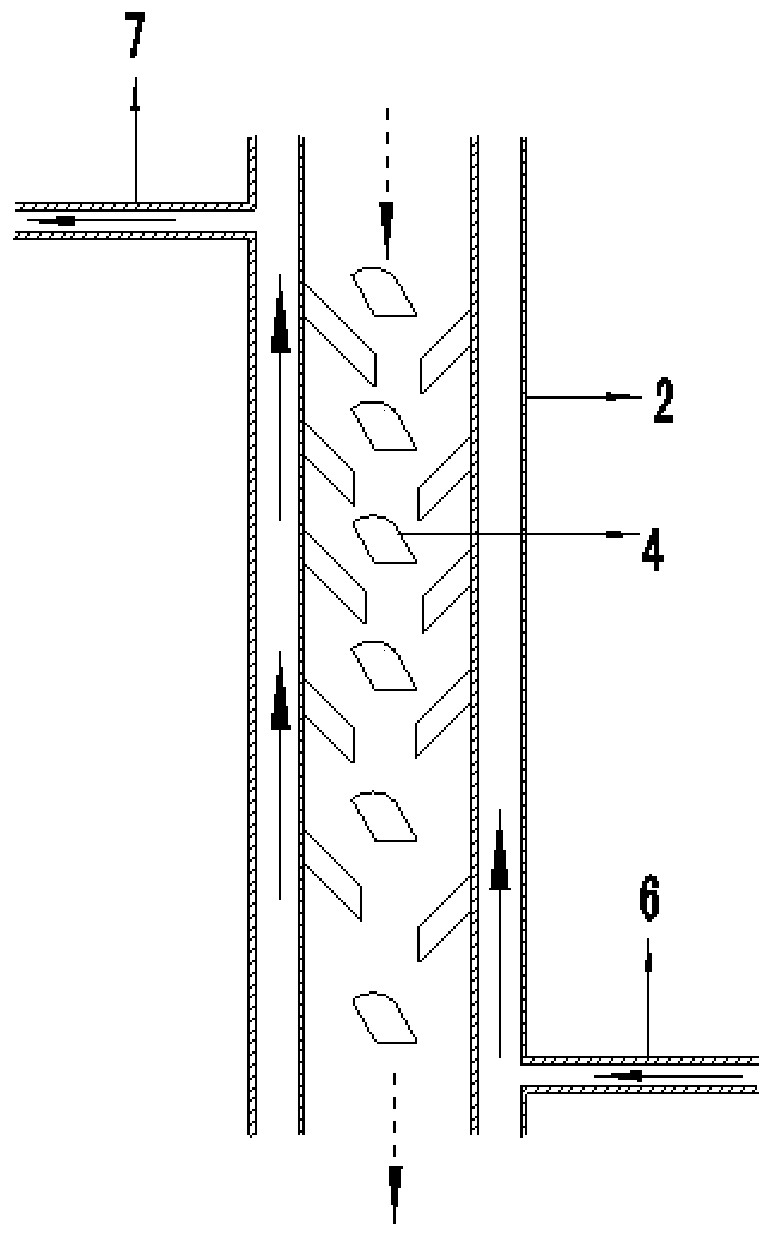

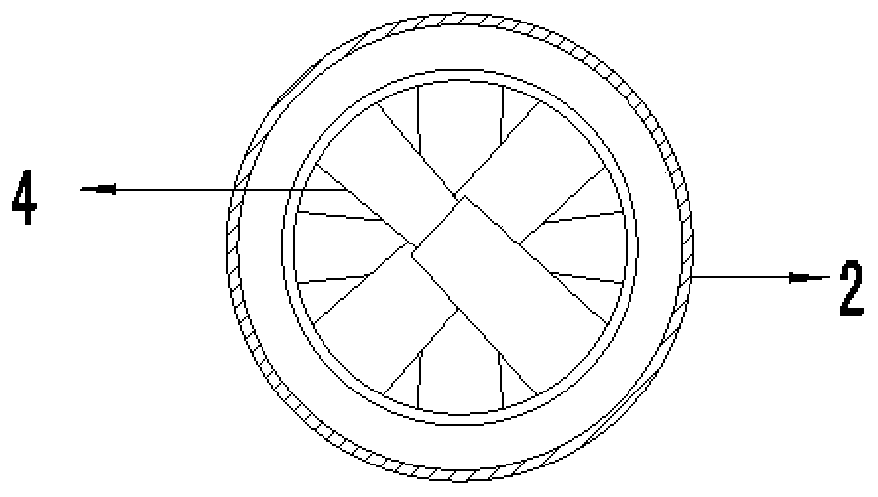

Device for treating chemical gaseous phase deposition furnace exhaust

PendingCN109806718APrevent affecting the pumping efficiencyReduce kinetic energyDispersed particle separationTarPulp and paper industry

The invention discloses a device for treating chemical gaseous phase deposition furnace exhaust. The upper end of an exhaust pipeline is communicated with a chemical gaseous phase deposition furnace body, and the lower end of the sandwich-structured exhaust pipeline is communicated with an inlet of a tar collection tank. An outlet of the tar collection tank is communicated with the inlet of a gaswasher through a cycle pipeline. A plurality of spirally-distributed baffle plates are distributed on the circumferential surface in the exhaust pipeline, so that exhaust generated by high-temperaturereaction in a chemical gaseous phase deposition furnace is intercepted and blocked layer by layer, a great amount of tar, dust, carbon black and the like is changed from gas into solid and condensedon the baffle plates and the wall of the exhaust pipeline, a great number of side products such as tar are prevented from being quickly absorbed into a vacuum system, long-time continuous operation ofthe vacuum system is maintained.

Owner:XIAN AVIATION BRAKE TECH

Photocatalysis apparatus and photocatalysis method

InactiveCN106975355ARealize strong oxidative decompositionTo achieve the purpose of purifying exhaust gasGas treatmentDispersed particle filtrationTowerPersonnel safety

The invention discloses a photocatalysis apparatus and a photocatalysis method. The photocatalysis apparatus mainly comprises a purification tower; the upper end of the purification tower is provided with a discharge outlet; the bottom surface of the purification tower is provided with air inlets uniformly; air outlet nozzles are respectively fixed to the air inlets through screws; the air inlets at the bottoms of the air outlet nozzles are in threaded connection with an air outlet of an air feeding pipe; the air feeding pipe is arranged on the outer side of the bottom of the purification tower; an air inlet of the air feeding pipe is connected with a waste-gas inlet / outlet pipe by welding. The photocatalysis apparatus has the advantage of convenience in refueling; during the whole treatment, conventional manual assembling and transporting is omitted, high-speed mechanical feeding and discharging is achieved, personnel safety is guaranteed, and circumstances such as positioning and hypoxia are avoided.

Owner:QINGDAO UNIV OF SCI & TECH

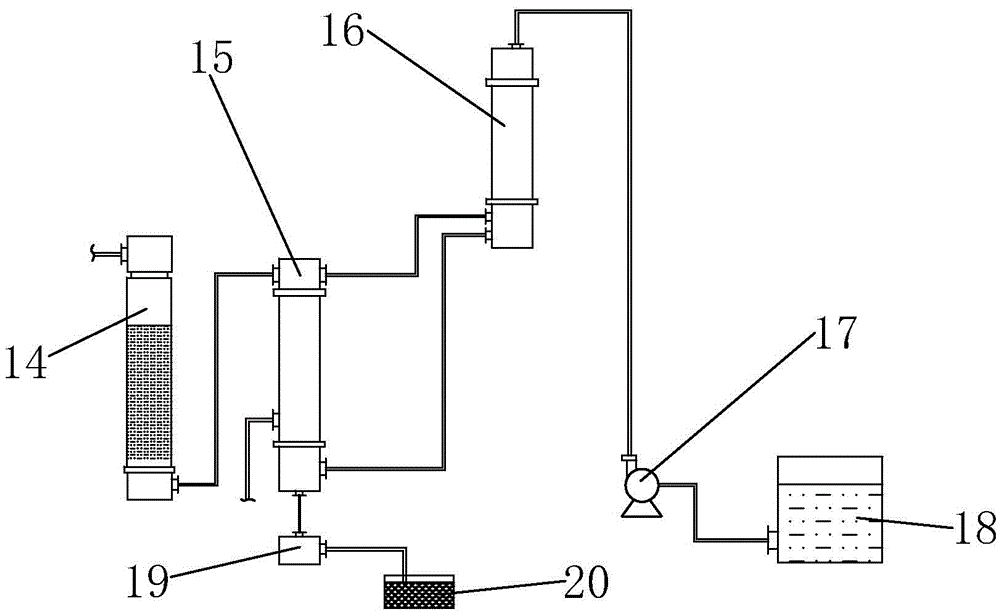

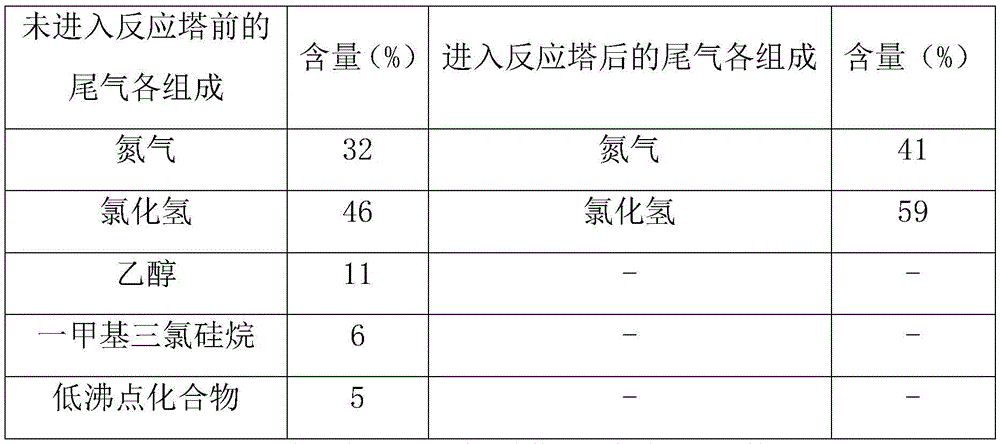

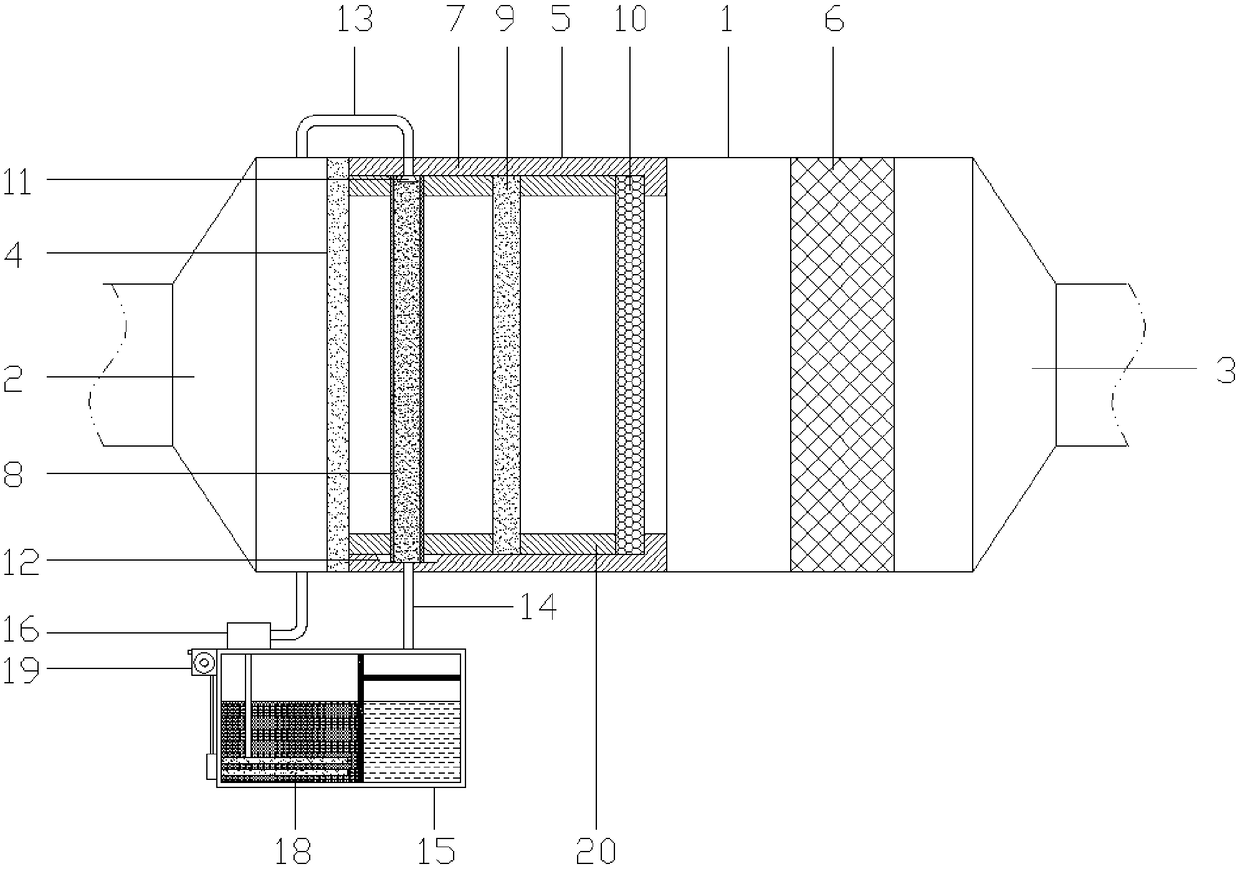

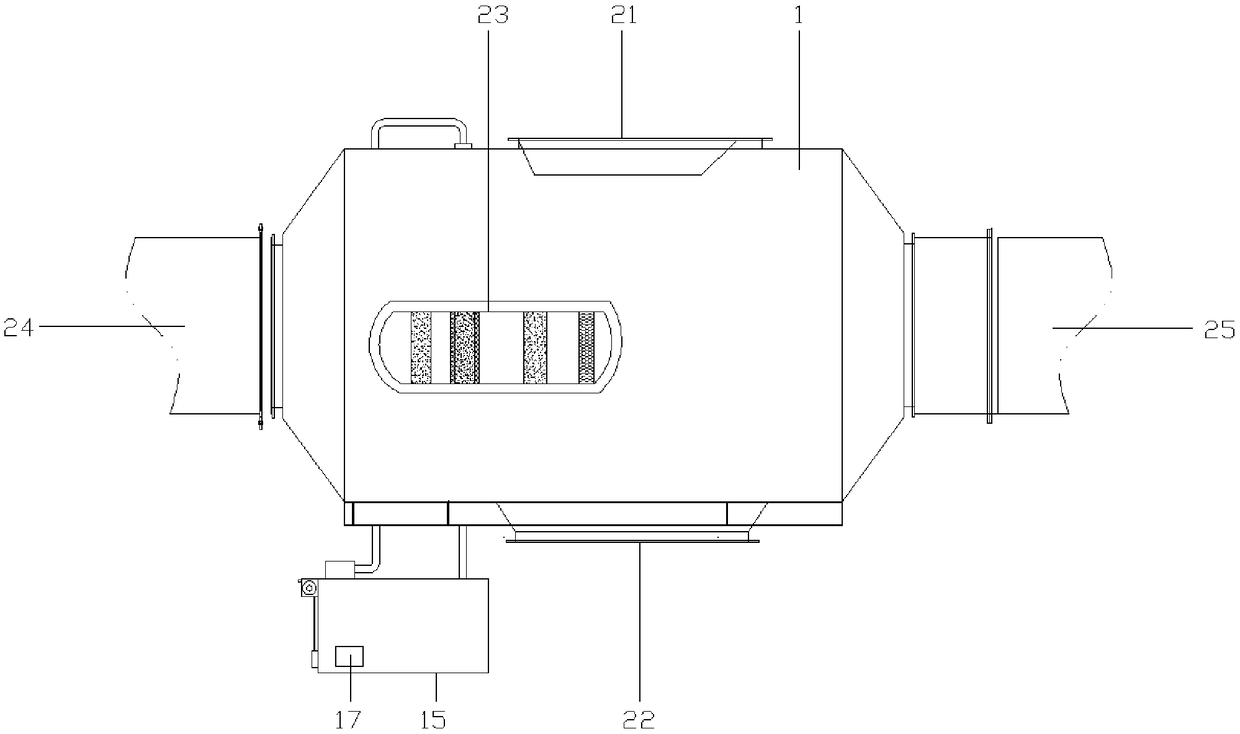

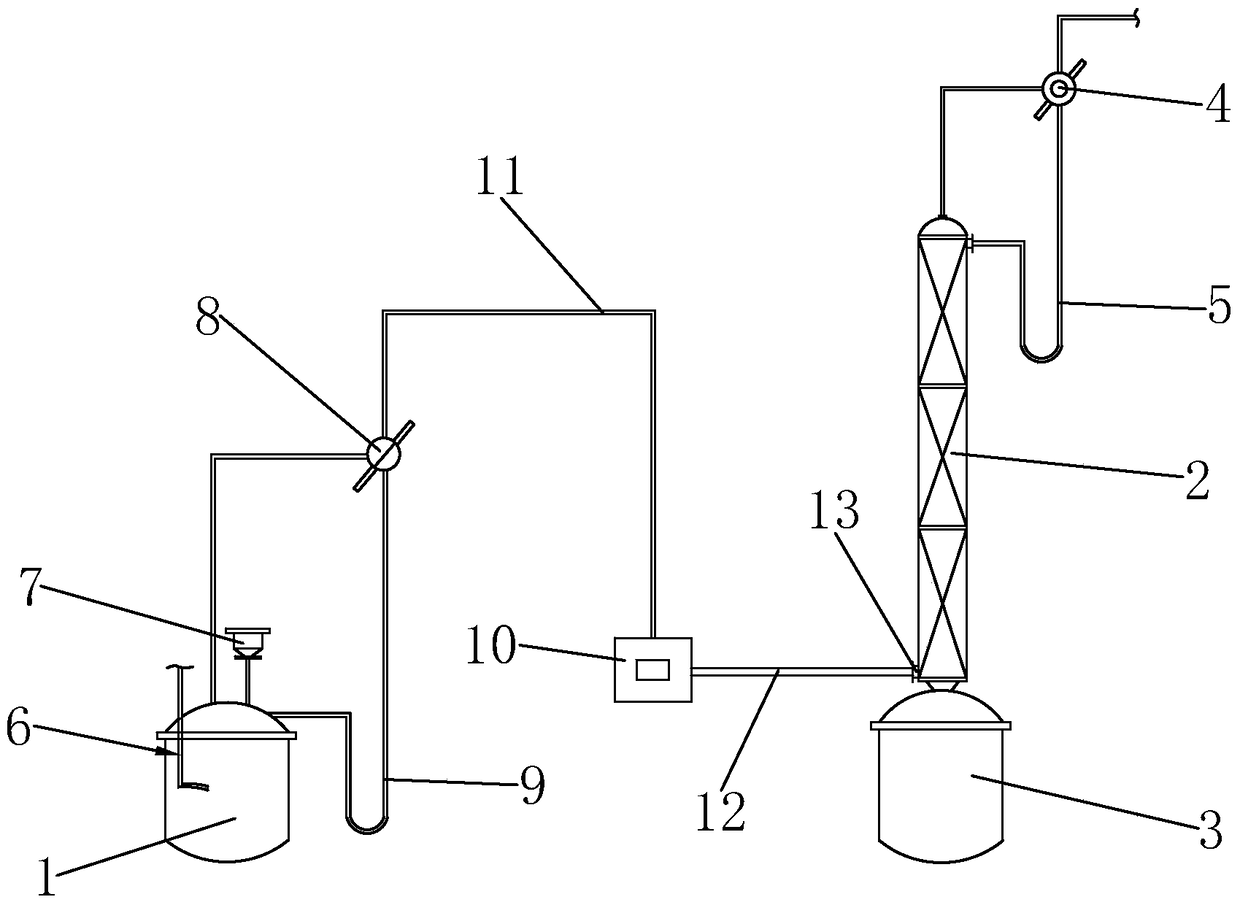

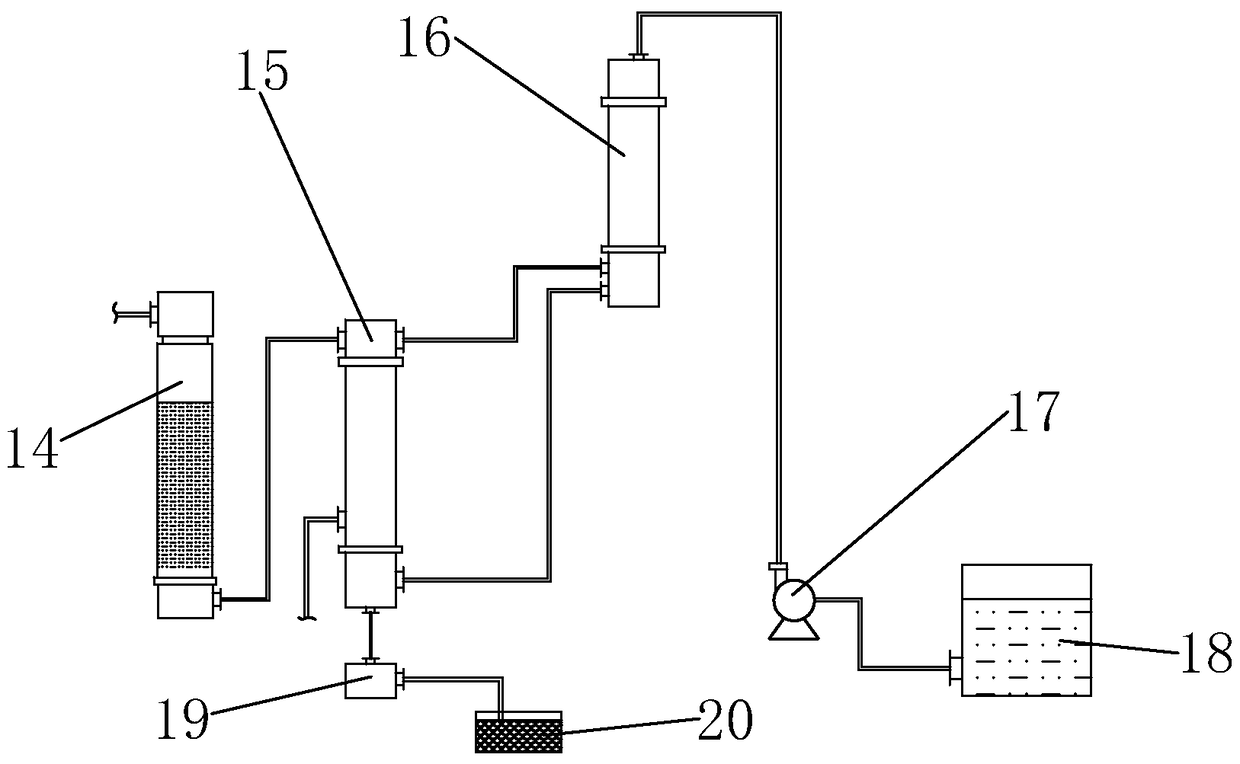

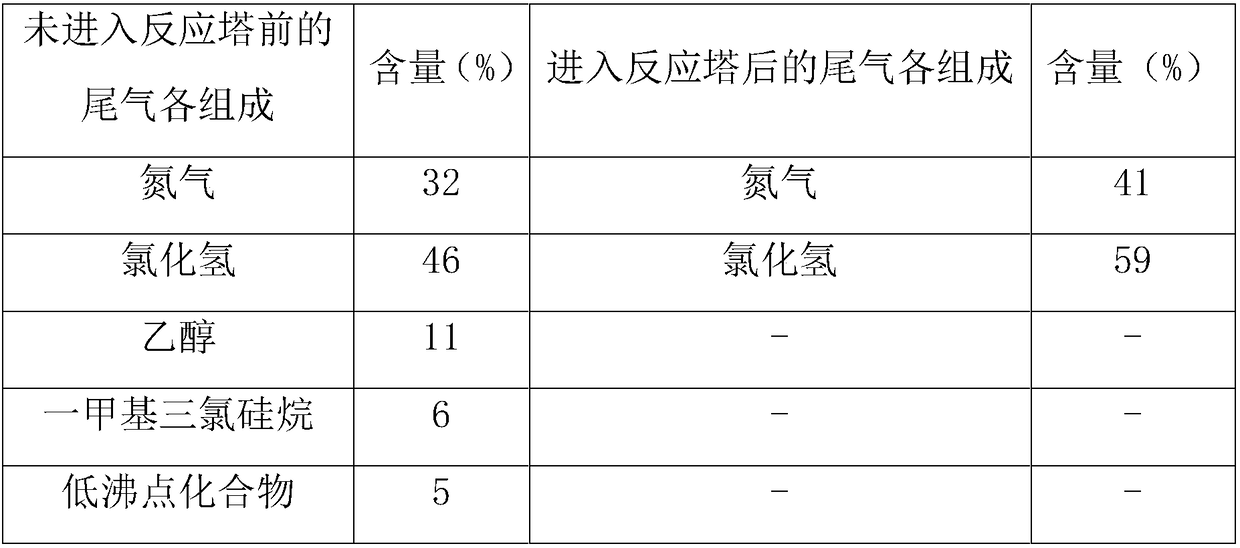

Absorption and utilization method of polymethyl triethoxy silane reaction exhaust

ActiveCN105597508AImprove absorption efficiencyHigh purityGroup 4/14 element organic compoundsDispersed particle separationExhaust gasZero emission

The present invention discloses an absorption and utilization method of polymethyl triethoxy silane reaction exhaust. The method comprises the steps of: (a) inspecting a reactor; (b) heating a reaction column; (c) conducting an alcoholysis reaction; (d) preheating tail gas; and (e) absorbing tail gas. The method improves the yield of the reaction, shortens reaction time, and that, eventually transforms the portion of the feed, which originally runs to a tail gas absorption system and is converted into a solid, into products. The equipment pipes and absorption column are no longer blocked, and the operation rate of absorption efficiency are greatly improved, and the purity of hydrochloric acid after tail gas absorption is greatly improved and close to authentic hydrochloric acid. The method turns waste into treasure, achieves zero emission, and is important to improving the technical level of polymethyl triethoxy silane synthesis and environmental protection.

Owner:ZHEJIANG QUZHOU ZHENGBANG ORGANOSILICON CO LTD

Low-temperature plasma waste gas purification equipment

InactiveCN108619817AExtended service lifeImprove air purification efficiencyCombination devicesGas treatmentActivated carbonWater storage tank

The invention discloses low-temperature plasma waste gas purification equipment. The low-temperature plasma waste gas purification equipment comprises a low-temperature plasma reaction chamber; the low-temperature plasma reaction chamber is provided with both a gas inlet and a gas outlet; a filtering net, a filtering device and a plasma generation device are arranged in the low-temperature plasmareaction chamber sequentially; the filtering device comprises a bracket as well as a filtering layer, a demisting layer and an activated carbon adsorbing layer which are arranged in the bracket sequentially; a spraying pipe is arranged at the top of the low-temperature plasma reaction chamber; a water return pipe is arranged at the bottom of the low-temperature plasma reaction chamber; one end ofthe water return pipe is connected with a water storage tank and the other end of the water return pipe is connected with an activated carbon water tank; and one end of the spraying pipe is connectedwith a spraying head and the other end of the spraying pipe is connected with the activated carbon water tank through a water pump. The low-temperature plasma waste gas purification equipment can prolong the service life and improve the gas purification effect, has a good purification effect on the waste gas, solves the problems of incomplete purification and insufficient purification degree, andenables the discharged gas to be more environment-friendly.

Owner:FOSHAN JIANJINJIAN ELECTRONICS TECH CO LTD

Waste gas purifying device and waste gas purifying system

PendingCN107596887AImprove purification effectLow investment costDispersed particle separationPlasma generatorCatalytic oxidation

The invention relates to the technical field of waste gas purification, and particularly relates to a waste gas purifying device and a waste gas purifying system. The waste gas purifying device comprises a low-temperature plasma purifying device and a photolysis catalytic oxidation device, wherein the photolysis catalytic oxidation device comprises a first shell, a catalyzing net and a plurality of UV lamp tubes arranged at interval; one end of the first shell is provided with a first air inlet, and the other end of the first shell is provided with a first air outlet; the catalyzing net and the plurality of UV lamp tubes are all arranged inside the first shell; the catalyzing net is arranged between the plurality of UV lamp tubes; the low-temperature plasma purifying device comprises a second shell, a plasma generator and a power supply; a second air outlet is communicated with the first air inlet. According to the waste gas purifying device provided by the invention, waste gas is purified through the low-temperature plasma generator, the purified waste gas is purified through the photolysis catalytic oxidation device, and the waste gas is purified twice, so that the purifying effect is higher.

Owner:唐山铸锐环保科技有限公司

Chinese medicinal herb smashing device

ActiveCN109012995AReach the purpose of recyclingAvoid wastingSievingDispersed particle filtrationMedicinal herbsResource utilization

The invention discloses a Chinese medicinal herb smashing device which comprises a machine case. A feeding hopper is installed on one side of the upper surface of the machine case, a separating plateis fixed to the top end of the interior of the machine case and divides the upper portion of the interior of the machine case into a dust removal chamber and a smashing chamber, the smashing chamber communicates with the dust removal chamber, a stirring bin is fixed to the position, close to the lower portion of the dust removal chamber, inside the machine case through a support, a first conveyingpipe is connected between the top of the stirring bin and the bottom end of the dust removal chamber, and a dust removal pipe is connected to the bottom end of the stirring bin. The Chinese medicinalherb smashing device is provided with the stirring bin and a smashing box, recovering and using of crushed materials are achieved, the resource using rate is improved, and the production benefits ofthe smashing device is are increased; and a first flow guide plate, a first arc-shaped upper wall, a first flow guide block, a second flow guide plate, a second arc-shaped upper wall and a second flow guide block are arranged, the flowing state and the flowing speed of medicinal herbs are adjusted, quick discharge of the medicinal herbs is promoted, pipe blockage is prevented, and the productionefficiency of the device is improved.

Owner:重庆三峡云海药业股份有限公司

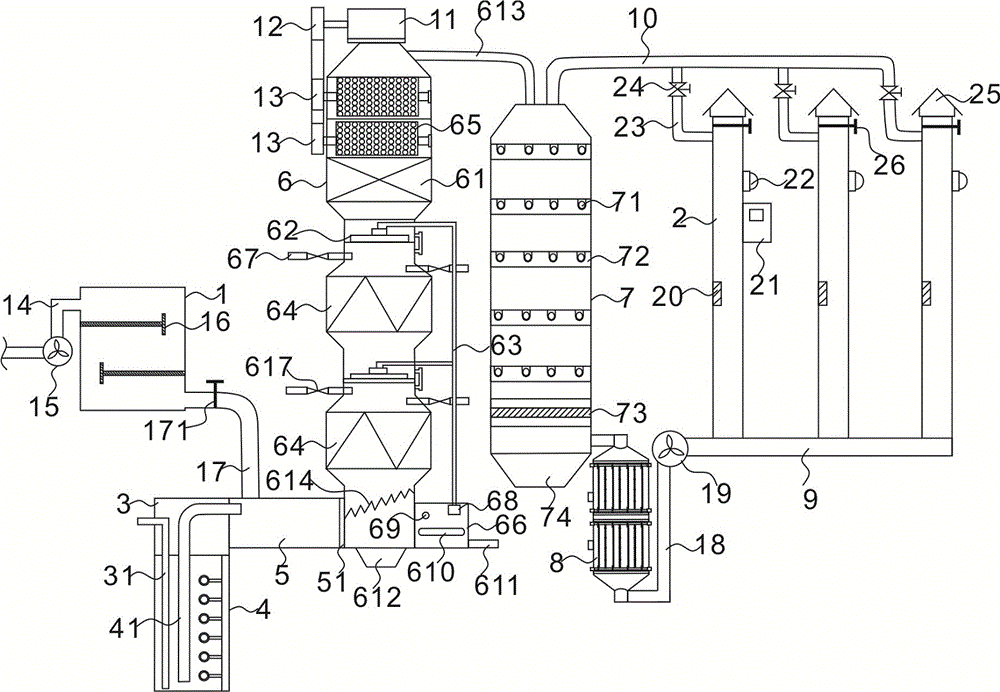

Micro quantum organic waste gas and odor integrated processing system

InactiveCN106362563AAdjust the ecological environmentAvoid destructionCombination devicesGas treatmentWater sourcePhysics

The invention provides a micro quantum organic waste gas and odor integrated processing system, and belongs to the technical field of organic waste gas processing equipment. The micro quantum organic waste gas and odor integrated processing system comprises a micro quantum ecosystem ball recirculating water treatment system, a micro quantum nanophase material internal coating, a microbiota strain processing system and the like, wherein primary decomposition treatment is performed on organic waste gas through physical and chemical effect caused by the micro quantum nanophase material internal coating, and then multiple strains in the microbiota strain processing system devour and decompose organic substances, and therefore the purpose of purifying the organic waste gas is achieved. Additionally, a clear water source is provided to microorganisms and waste water generated by the microbiota strain processing system is purified through the micro quantum ecosystem ball recirculating water treatment system. The micro quantum organic waste gas and odor integrated processing system has the advantages of being thorough in purification, lasting in purification effect, and easy to manage.

Owner:佛山市保能特知识产权管理有限公司 +1

Breeding waste gas treatment device

ActiveCN112588098AEasy to irradiateSpread evenlyGas treatmentDispersed particle separationHazardous substanceEnvironmental engineering

The invention relates to the technical field of purification equipment, in particular to a breeding waste gas treatment device which can effectively reduce the content of harmful substances in waste gas, improve the waste gas purification effect, prevent the waste gas from damaging the external environment and improve the practicability and reliability by purifying the waste gas. The device comprises a light collecting treatment bin, an air inlet pipe, a one-way valve, four sets of extrusion cylinders and four sets of threaded sleeves; the light collecting treatment bin is round, the air inletpipe is communicated with the top of the light collecting treatment bin, the one-way valve is installed on the air inlet pipe, and the four sets of extrusion cylinders are evenly communicated with the outer side wall of the light collecting treatment bin in the radial direction of the light collecting treatment bin; and the four sets of threaded sleeves are installed at the outer ends of the foursets of extrusion cylinders correspondingly.

Owner:诸城市中裕机电设备有限公司

Meat product processing device with high resource utilization

InactiveCN108812828AAchieve recyclingIncrease profitDispersed particle filtrationTreatment involving filtrationAir filtrationQuality of work

The invention discloses a meat product processing device with high resource utilization. The device comprises an outer tank, wherein a charge hopper is arranged at the top end of the outer tank, and an inner tank is fixed at the center inside the outer tank through two fixing racks; an induced draft fan is arranged on the upper surface of one fixing rack, and an air inlet pipe is connected betweenthe air inlet end of the induced draft fan and the inner tank; a rotary plate is connected at the bottom end of the inner tank through a rotating shaft in a rotating manner, and a hydraulic rod is connected at the bottom of the rotary plate; a hydraulic cylinder is arranged at the bottom of the hydraulic rod. According to the device, a third check valve, a waste water purifying tank, an ultrafiltration membrane filter layer and a return pipe are provided, the aim of purifying wastewater is achieved, the water resource can be recycled, and the utilization of resources can be improved; and an air delivery pipe, the induced draft fan, the air inlet pipe, an air filter tank, an activated carbon filter screen and an exhaust valve are provided, exhaust gas can be purified, air pollution causedby exhaust gas emission can be avoided, and the quality of working environment of workers can be improved.

Owner:季一全

Waste gas purification treatment method

ActiveCN111389197ATo achieve the purpose of purifying exhaust gasEasy to operateCombination devicesGas treatmentPtru catalystUltraviolet lights

The invention relates to a waste gas purification treatment method. The method comprises the following steps: s1, connecting a water source into a water inlet pipe so that the water is sprayed out from an atomizing nozzle; s2, introducing waste gas, and humidifying and spraying the waste gas; s3, starting an induced draft fan and an air blower, and feeding the gas in the S2 into the bottom of thetreatment chamber; and S4, moving the waste gas in the treatment chamber from bottom to top, and preliminarily filtering through a filter material plate so that harmful organic matter in the waste gasand a catalyst fixed to the filter material plate are decomposed under the catalytic action. According to the invention, waste gas is sprayed; according to the waste gas treatment device, the waste gas is preliminarily filtered by the filter material plate, harmful organic matters in the waste gas and a catalyst fixed on the filter material plate are decomposed under the catalytic action, residual particles in the waste gas are adsorbed by a filter screen II, and finally, the waste gas is purified and sterilized by a ultraviolet lamp, so that the purpose of purifying the waste gas is achieved, and the device is simple, convenient to operate and good in removal effect.

Owner:潍坊博锐环境保护有限公司

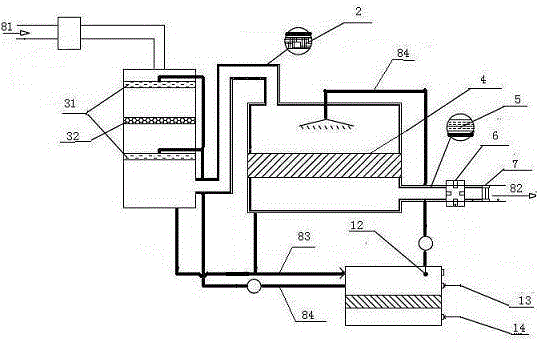

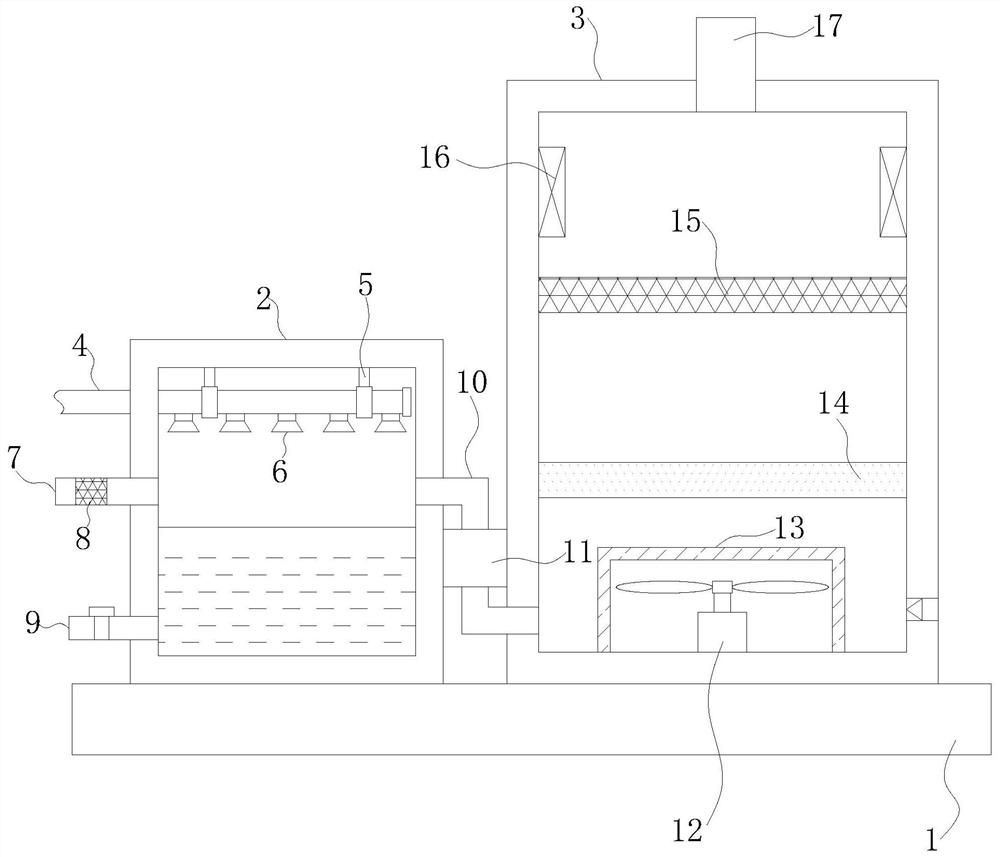

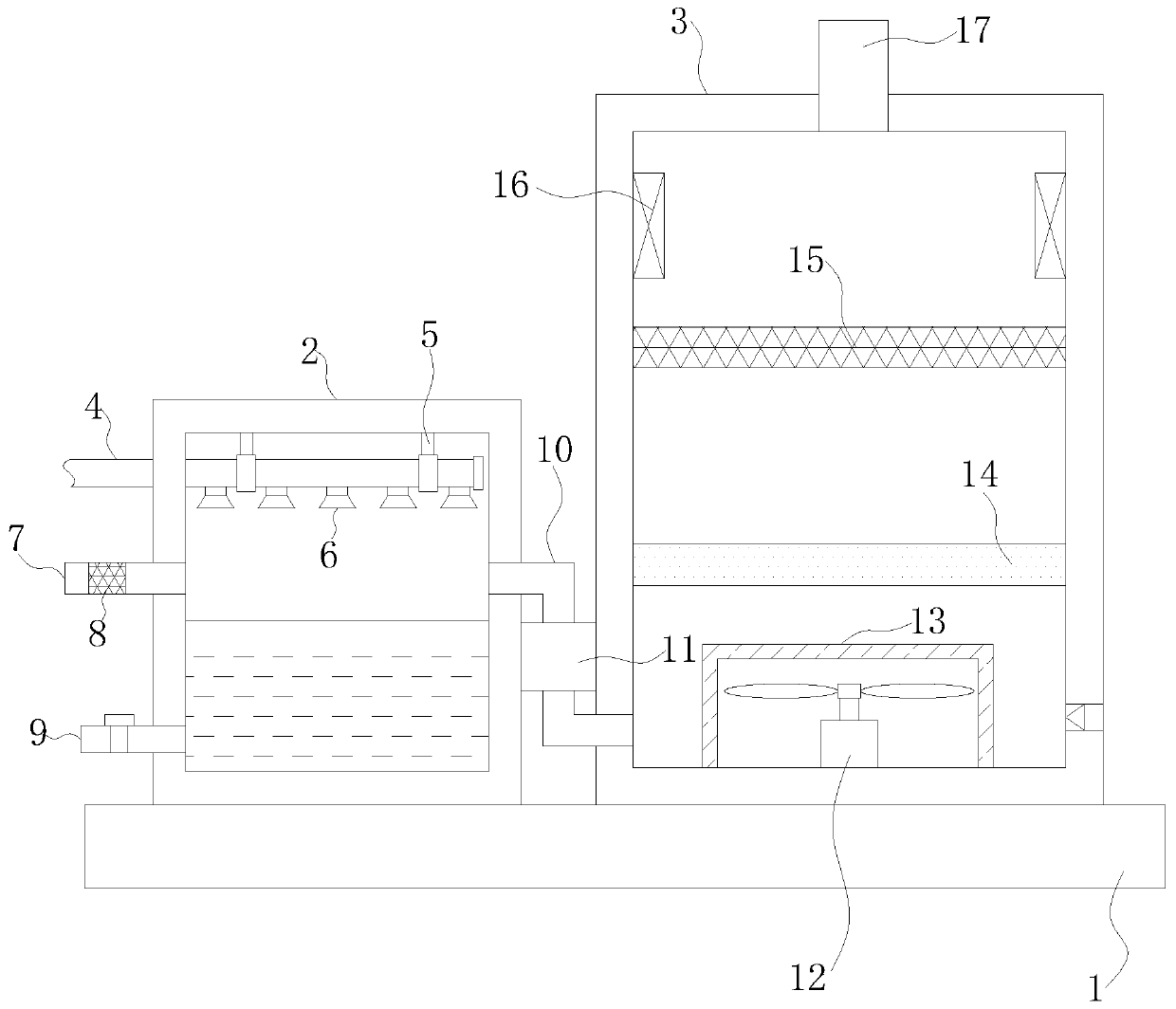

Waste gas treatment equipment

InactiveCN111389200ATo achieve the purpose of purifying exhaust gasEasy to operateCombination devicesGas treatmentPtru catalystUltraviolet lights

The invention relates to the technical field of waste gas treatment, and discloses waste gas treatment equipment. The equipment comprises a bottom plate, a humidifying chamber is fixedly connected tothe left side of the top of the bottom plate, a treatment chamber is fixedly connected to the right side of the top of the bottom plate, a water inlet pipe is arranged at the top of the bottom plate,penetrates through the humidifying chamber and extends into the humidifying chamber, supports are fixedly connected to the outer surfaces of the two ends of the humidifying chamber, and the tops of the two supports are fixedly connected with the humidifying chamber. According to the invention, waste gas is sprayed; the waste gas is preliminarily filtered by the filter material plate, harmful organic matters in the waste gas and a catalyst fixed on the filter material plate are decomposed under the catalytic action, residual particles in the waste gas are adsorbed by a filter screen II, and finally, the waste gas is purified and sterilized by the ultraviolet lamp, so that the purpose of purifying the waste gas is achieved, and the equipment is simple, convenient to operate and good in removal effect.

Owner:铭牌精工机械(山东)有限公司

A waste gas purification treatment method

ActiveCN111389197BTo achieve the purpose of purifying exhaust gasEasy to operateCombination devicesGas treatmentPtru catalystUltraviolet lights

Owner:潍坊博锐环境保护有限公司

A waste gas treatment device

InactiveCN105674303BBurn fullyImprove combustion efficiencyIncinerator apparatusProcess engineeringTherapeutic effect

The invention discloses a waste gas treatment device.The waste gas treatment device comprises a first shell, a heating device, a first heat exchanger, a VOC organic waste gas purification catalyst, a noble metal catalyst, a second heat exchanger and an outer cover, wherein a gas inlet interface and a gas outlet interface are formed in the front end and the back end of the first shell, the first shell is provided with a first cavity and a second cavity, the heating device is arranged in the first cavity, the first heat exchanger comprises a first heat exchange pipe arranged on the side of the heating device, the VOC organic waste gas purification catalyst is arranged in the first cavity, the noble metal catalyst is arranged in the first cavity, the second heat exchanger comprises a second heat exchange pipe and a fan which are arranged in the second cavity, and the outer cover is arranged on the periphery of the first shell.A first passage hole and a second passage hole respectively communicated with the first cavity and the second cavity are respectively formed in the bottom and the top of the first shell, a first passage cover plate for communication between the first passage port and the upper port of the first heat exchange pipe is arranged at the bottom of the first shell, and a second passage cover plate for communication between the lower port of the first heat exchange pipe and the second passage port is arranged at the top of the first shell.The waste gas treatment device can completely combust waste gas and has a very good purification treatment effect.

Owner:东莞市鑫睿思环保科技有限公司

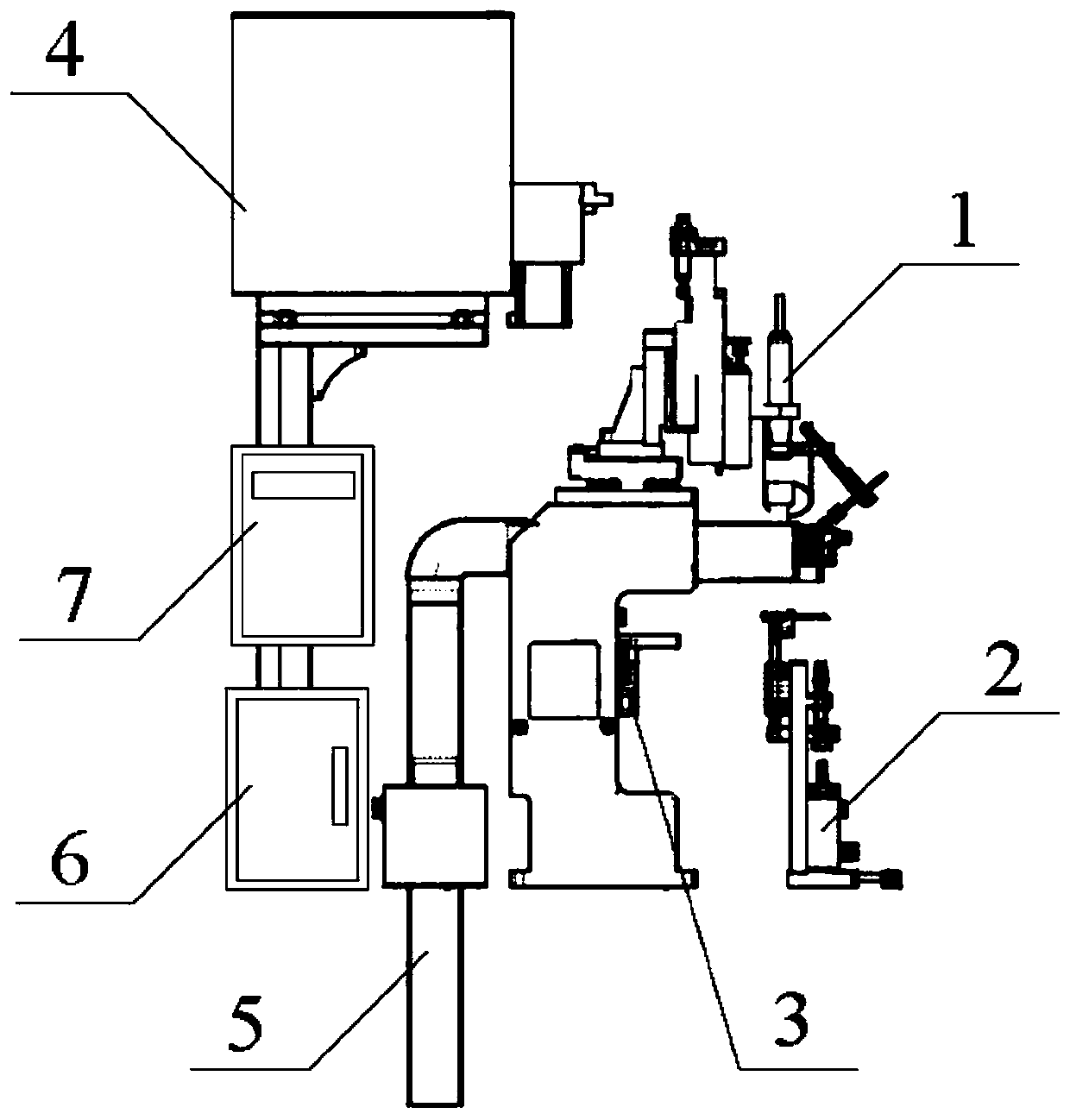

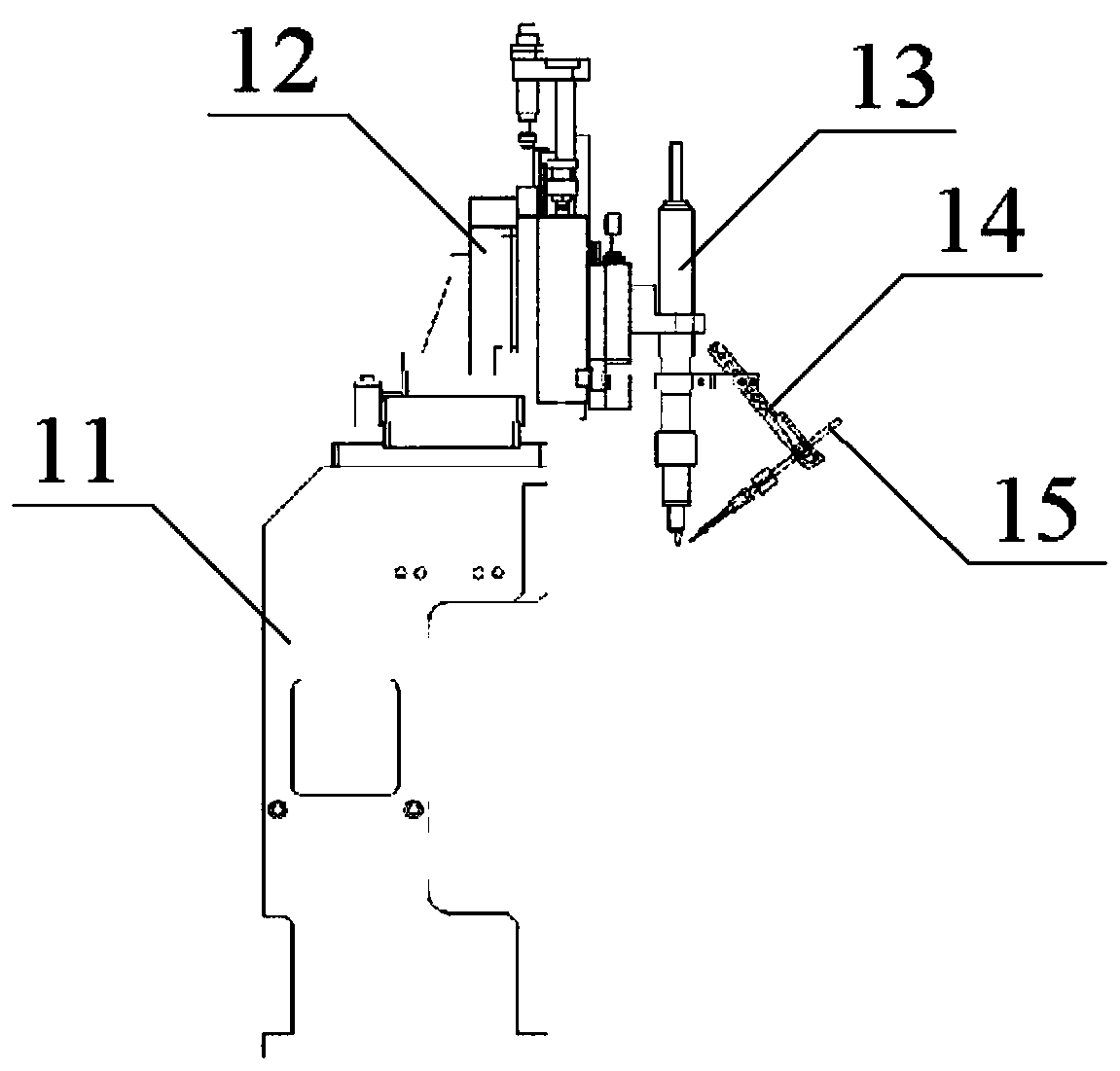

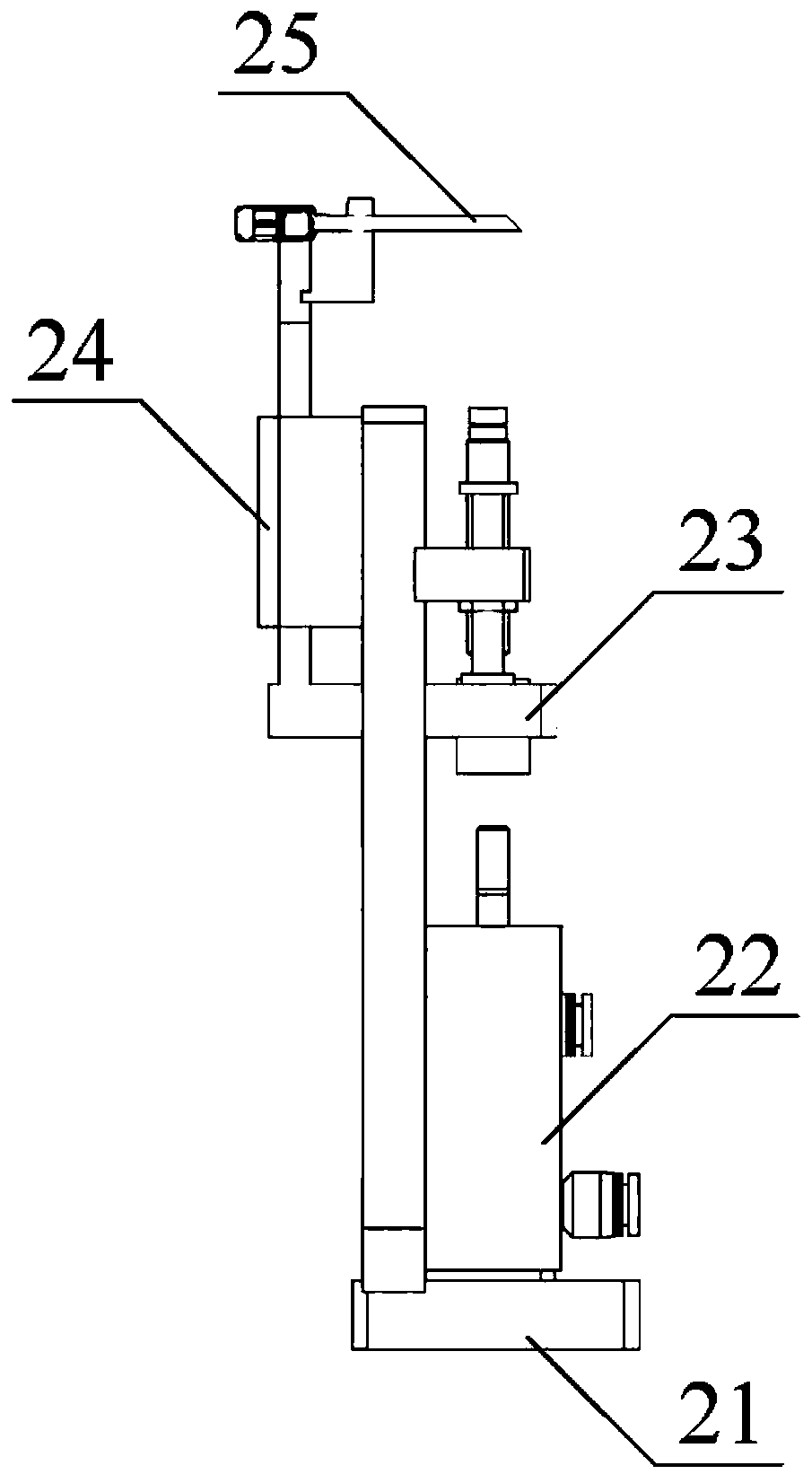

Automatic welding equipment realizing automatic tin feeding

ActiveCN110919127ADiverse welding functionsReduce dosageMetal working apparatusSolder feeding devicesProcess engineeringSpot welding

The invention discloses an automatic welding equipment realizing automatic tin feeding. The automatic welding equipment comprises a welding component, a product positioning component, a clamp positioning component, an automatic tin feeding component, a waste gas processing component, an electric control cabinet and a PLC. According to the automatic welding equipment disclosed by the invention, theautomatic tin feeding component and the welding component are arranged; the PLC is used for controlling a wire sending motor and a welding handle to act; the wire conveying motor is used for sendinga wire disc positioned on a wire disc rod into a tin feeding pipe via a wire discharging opening so as to realize the aims of automatic wire conveying and automatic welding; compared with a method adopting manual tin welding, the automatic welding equipment disclosed by the invention is more varied in welding function; to spot welding, the use amount can be saved by 15% based on manual welding; the waste gas processing component is arranged and an air exhaust fan is powered on to run in a welding process so as to convey waste gas generated in the welding process into a purifier, and then the waste gas is discharged after being purified, thus the aim of purification of the waste gas is realized; and harms caused by the waste gas to the body health of an operator are prevented.

Owner:CHANGDE FUBO INTELLIGENCE TECH CO LTD

A catalytic ceramic sintered ring for exhaust gas treatment and its preparation method

InactiveCN105214706BTo achieve the purpose of purifying exhaust gasImprove productivityDispersed particle separationRaney catalystsActivated carbonCeramic sintering

The invention belongs to the technical field of waste gas purification materials, and in particular relates to a catalytic ceramic sintering ring for waste gas treatment and a preparation method. The catalytic ceramic sintering ring comprises the following components by weight: 2-6% of alumina; 3% of titanium dioxide ~4%; iron oxide 3~5%; zirconia 3~4%; lanthanum oxide 4~5%; cerium oxide 3~6%; praseodymium oxide 2~4%; zinc oxide 4~5%; activated carbon powder 30~ 35%; silicon carbide 40-45%. The catalytic ceramic sintered ring for exhaust gas treatment proposed by the invention has high catalytic reaction efficiency and remarkable exhaust gas purification efficiency.

Owner:HANGZHOU ZHENGQING ENVIRONMENTAL PROTECTION SCI & TECH

A method for absorbing and utilizing polymethyltriethoxysilane reaction tail gas

ActiveCN105597508BIncrease contact areaMake sure the reaction is completeGroup 4/14 element organic compoundsDispersed particle separationSilanesAbsorption column

The present invention discloses an absorption and utilization method of polymethyl triethoxy silane reaction exhaust. The method comprises the steps of: (a) inspecting a reactor; (b) heating a reaction column; (c) conducting an alcoholysis reaction; (d) preheating tail gas; and (e) absorbing tail gas. The method improves the yield of the reaction, shortens reaction time, and that, eventually transforms the portion of the feed, which originally runs to a tail gas absorption system and is converted into a solid, into products. The equipment pipes and absorption column are no longer blocked, and the operation rate of absorption efficiency are greatly improved, and the purity of hydrochloric acid after tail gas absorption is greatly improved and close to authentic hydrochloric acid. The method turns waste into treasure, achieves zero emission, and is important to improving the technical level of polymethyl triethoxy silane synthesis and environmental protection.

Owner:ZHEJIANG QUZHOU ZHENGBANG ORGANOSILICON CO LTD

A waste gas purification treatment equipment

ActiveCN111389198BTo achieve the purpose of purifying exhaust gasEasy to operateCombination devicesGas treatmentPtru catalystUltraviolet lights

Owner:潍坊博锐环境保护有限公司

Waste gas purification treatment equipment

ActiveCN111389198ATo achieve the purpose of purifying exhaust gasEasy to operateCombination devicesGas treatmentPtru catalystUltraviolet lights

The invention relates to waste gas purification treatment equipment. The equipment comprises a bottom plate, a humidifying chamber is fixedly connected to the left side of the top of the bottom plate,a treatment chamber is fixedly connected to the right side of the top of the bottom plate, a water inlet pipe is arranged at the top of the bottom plate, penetrates through the humidifying chamber and extends into the humidifying chamber, supports are fixedly connected to the outer surfaces of the two ends of the humidifying chamber, and the tops of the two supports are fixedly connected with thehumidifying chamber. According to the invention, waste gas is sprayed; the waste gas is preliminarily filtered by the filter material plate, harmful organic matters in the waste gas and a catalyst fixed on the filter material plate are decomposed under the catalytic action, residual particles in the waste gas are adsorbed by a filter screen II, and finally, the waste gas is purified and sterilized by a ultraviolet lamp, so that the purpose of purifying the waste gas is achieved, and the equipment is simple, convenient to operate and good in removal effect.

Owner:潍坊博锐环境保护有限公司

A breeding waste gas treatment device

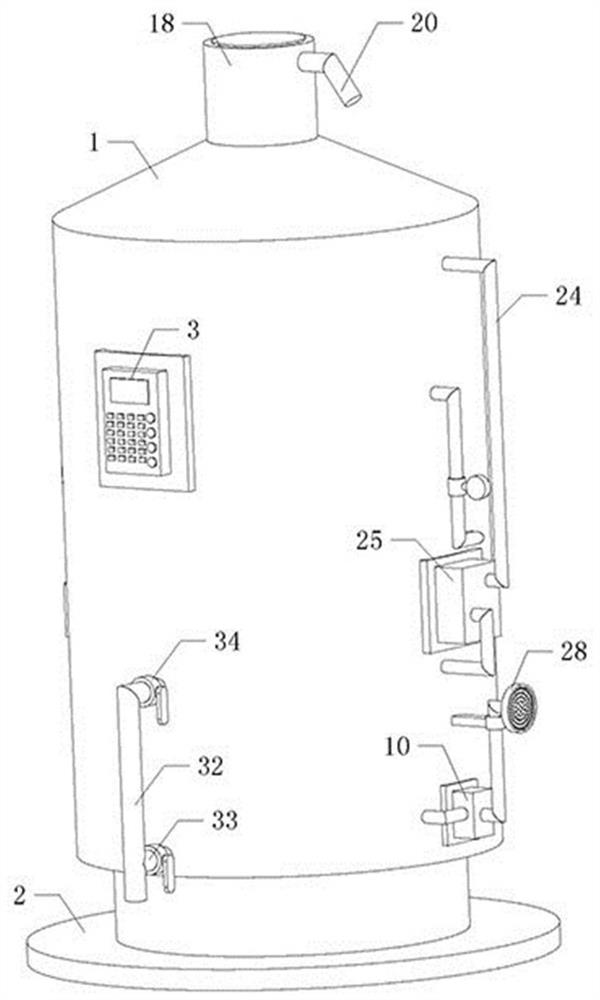

ActiveCN111957172BEasy to monitor in real timeAir pressure real-time monitoringGas treatmentDispersed particle separationAnimal scienceDomestic bird

The invention relates to the technical field of purification equipment, in particular to a breeding waste gas treatment device which can effectively improve the air quality in a poultry breeding room,improve the living environment of poultry, prevent waste gas from being directly discharged into outside air and damaging the environment, prevent a human body from inhaling the waste gas and injuring the human body and improve the practicability and reliability by purifying the waste gas. The device comprises a purification bin, a base, a central control box, a first partition plate, a second partition plate and an air guide channel. The top of the purification bin is conical, the base is installed at the bottom of the purification bin, the central control box is installed on the upper frontside of the purification bin, and the first partition plate is installed on the lower side of the inner wall of the purification bin.

Owner:SHANDONG HENGIN AGRI & ANIMAL HUSBANDRY MACHINERY

Cutting device for leather cutting

ActiveCN108950095BPrevent splashEasy to cleanLeather clicking/perforating/clickingElectric machineryWorkbench

The invention discloses a cutting device for cutting off leather. A machine case body is included, and a cutting bin is installed above the machine case body; the middle position of the upper surfaceof the machine case body is provided with a workbench; the middle position of the top end in the cutting bin is provided with a cross beam; a lead screw motor is installed on one side of the cross beam; a lead screw rotationally connected with the lead screw motor is fixed to one side of the cross beam; a movable base is in transmission connection with the middle position of the cross beam throughthe lead screw; and a second electric cylinder is installed at the bottom in the movable base. The cutting device for cutting off the leather is provided with a material collecting groove and a material sucking machine, collecting of broken materials is achieved, it is prevented that the broken materials are scattered, clearing by a worker is facilitated, a cyclone separator and a purifying box are arranged, waste gas purifying is achieved, it is prevented that waste gas is exhausted, and air pollution is caused, and it is achieved that the cutting device is more environment-friendly; and a heat recoverer is arranged, waste heat recycling of gas is achieved, the utilizing rate of resources is increased, and it is achieved that the cutting device saves more energy.

Owner:JIAXING LONGJUN INFORMATION TECH

Cutting device for cutting off leather

ActiveCN108950095APrevent splashEasy to cleanLeather clicking/perforating/clickingEngineeringAir pollution

The invention discloses a cutting device for cutting off leather. A machine case body is included, and a cutting bin is installed above the machine case body; the middle position of the upper surfaceof the machine case body is provided with a workbench; the middle position of the top end in the cutting bin is provided with a cross beam; a lead screw motor is installed on one side of the cross beam; a lead screw rotationally connected with the lead screw motor is fixed to one side of the cross beam; a movable base is in transmission connection with the middle position of the cross beam throughthe lead screw; and a second electric cylinder is installed at the bottom in the movable base. The cutting device for cutting off the leather is provided with a material collecting groove and a material sucking machine, collecting of broken materials is achieved, it is prevented that the broken materials are scattered, clearing by a worker is facilitated, a cyclone separator and a purifying box are arranged, waste gas purifying is achieved, it is prevented that waste gas is exhausted, and air pollution is caused, and it is achieved that the cutting device is more environment-friendly; and a heat recoverer is arranged, waste heat recycling of gas is achieved, the utilizing rate of resources is increased, and it is achieved that the cutting device saves more energy.

Owner:JIAXING LONGJUN INFORMATION TECH

A breeding waste gas treatment device

ActiveCN112588098BEasy to irradiateSpread evenlyGas treatmentDispersed particle separationHazardous substanceEnvironmental engineering

The invention relates to the technical field of purification equipment, in particular to a farming waste gas treatment device, which can effectively reduce the content of harmful substances in the waste gas by purifying the waste gas, improve the purification effect of the waste gas, and prevent the waste gas from causing damage to the external environment. Improve practicability and reliability; including light-collecting processing chamber, air intake pipe, one-way valve, four sets of extrusion cylinders and four sets of screw sleeves, the shape of the light-collecting processing chamber is circular, and the intake pipe is connected and installed in the light-collecting processing chamber The top of the top, the one-way valve is installed on the intake pipe, the four sets of extrusion cylinders are evenly connected and installed on the outer wall of the light collection treatment chamber along the radial direction of the light collection treatment chamber, and the four sets of screw sleeves are respectively installed on the four sets of extrusion cylinders the outer end.

Owner:诸城市中裕机电设备有限公司

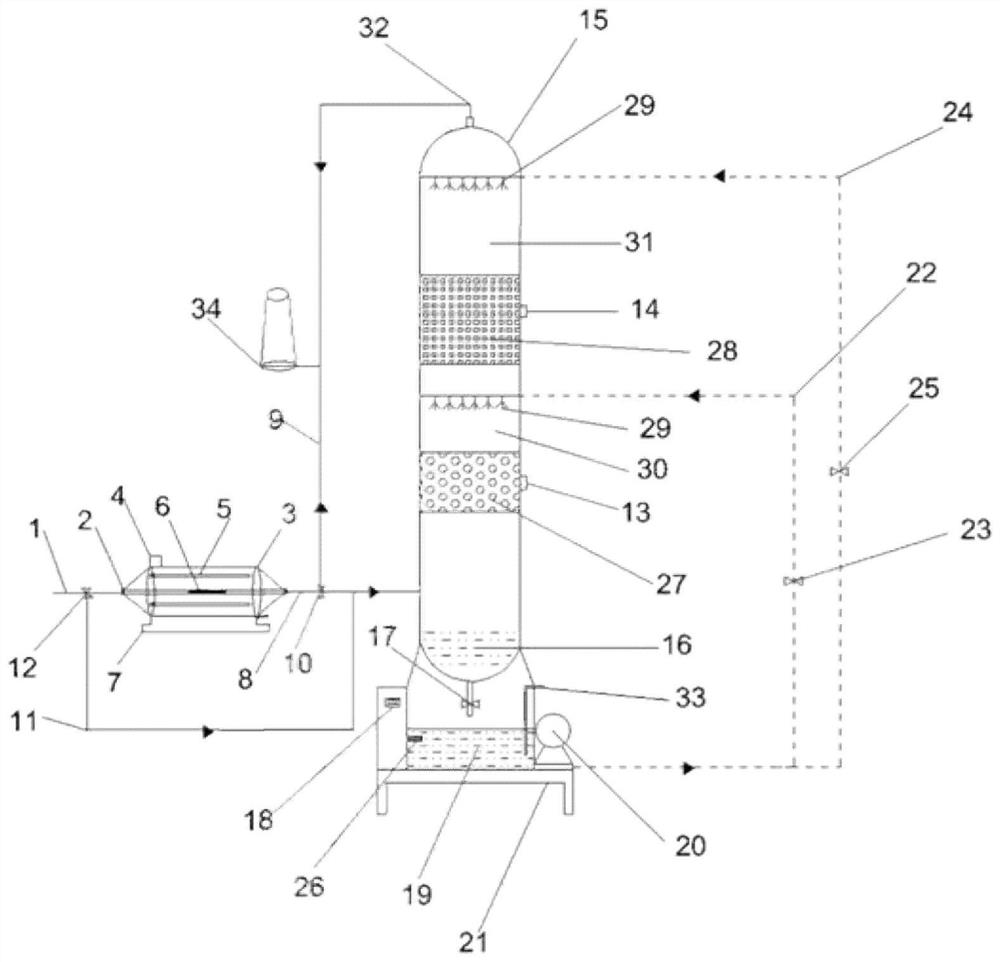

Waste gas treatment device employing coupling of ultraviolet catalytic oxidation and double-layer bio-trickling filter

PendingCN113398736AImprove processing efficiencyReduce concentrationGas treatmentDispersed particle separationMicroorganismCatalytic oxidation

The invention discloses a waste gas treatment device employing coupling of ultraviolet catalytic oxidation and a double-layer bio-trickling filter. The waste gas treatment device comprises ultraviolet catalytic oxidation equipment and double-layer bio-trickling filtration equipment, wherein an UV lamp tube and a MnOx / SiC composite photocatalyst are arranged in the ultraviolet catalytic oxidation equipment; the double-layer bio-trickling filtration equipment comprises the double-layer bio-trickling filter; a polyurethane biological flow bed and a polyurethane biological bottom bed are arranged in the bio-trickling filter at an interval along a vertical direction; and atomizing nozzles are respectively arranged above the polyurethane biological bed at the upper layer and above the polyurethane biological bed at the lower layer, and the atomizing nozzles are connected with a nutrient solution storage tank. According to the invention, pollutants in waste gas are purified through photocatalytic oxidation based on the oxidation-reduction capability of the MnOx / SiC composite photocatalyst under an illumination condition; and meanwhile, trace ozone generated by photocatalytic oxidation enters the double-layer bio-trickling filtration equipment, so the waste gas purification efficiency of microorganisms can be further improved. The device is suitable for treatment of low-flow high-concentration waste gas.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com