Absorption and utilization method of polymethyl triethoxy silane reaction exhaust

A polymethyltriethoxysilane and tail gas technology, which is applied in the field of absorption and utilization of polymethyltriethoxysilane reaction tail gas, can solve the problems of polluted environment, low purity, and reduced utilization rate of tail gas absorption, and achieves The effect of expanding the contact area, shortening the reaction time, and improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

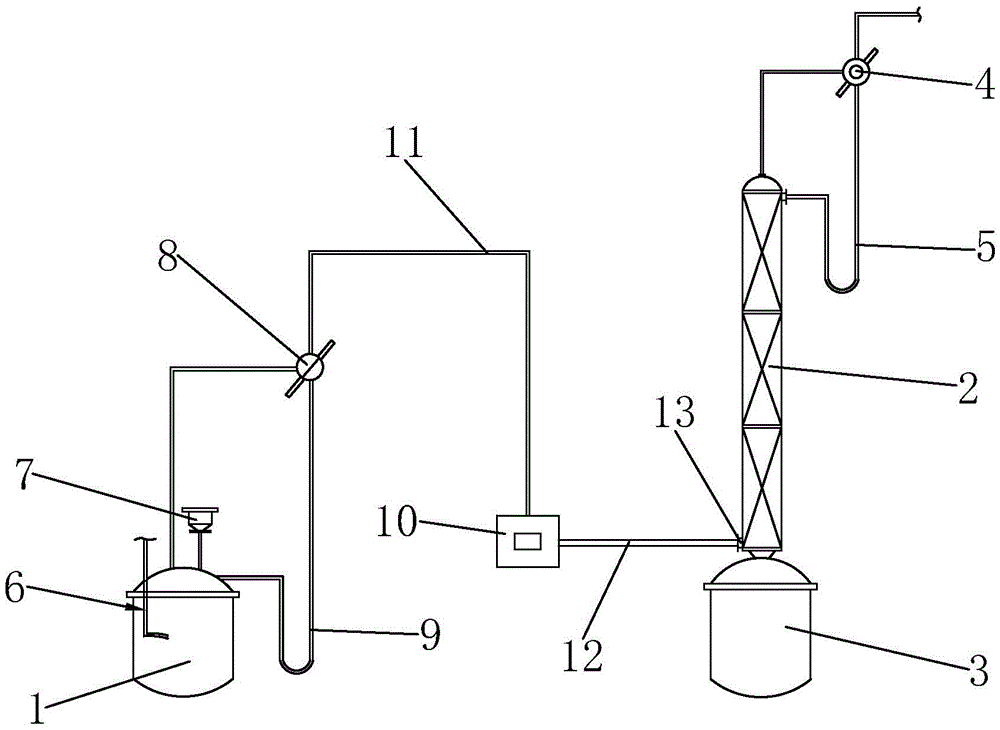

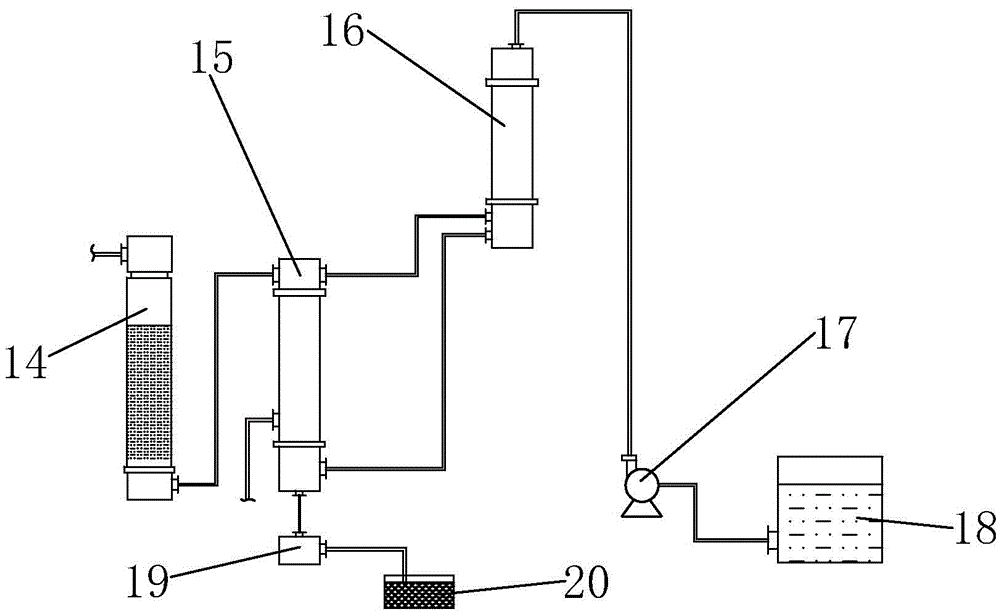

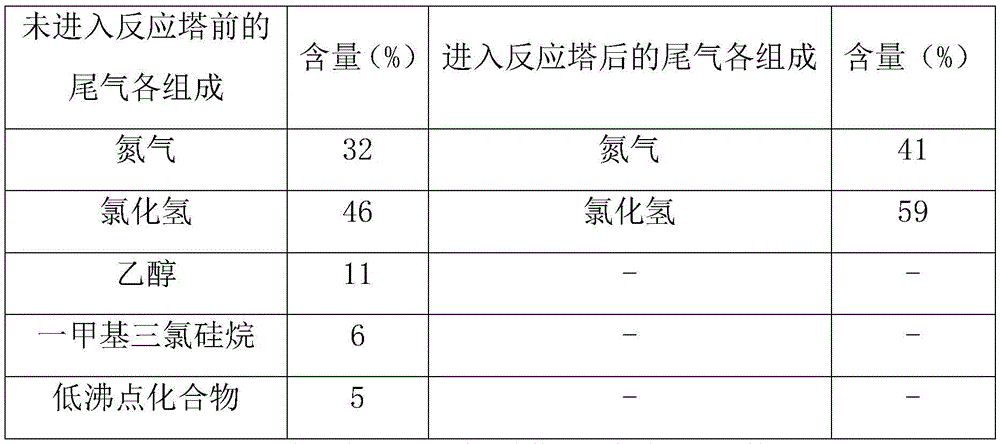

[0022] Such as figure 1 with figure 2 Shown is a method for absorbing and utilizing polymethyltriethoxysilane reaction tail gas of the present invention, which includes the following steps:

[0023] (a) Check the reaction device: first check whether the airtightness of the reactor 1, the reactor 2 and the reactor 3 meet the standard by conventional methods, to avoid equipment leakage during the reaction, affect the reaction efficiency, and increase the reaction time. Then use the high-pressure water gun to wash the inner walls of the reactor 1 and the tower 3, gradually wash from top to bottom, the washing time lasts 15-20 minutes, and wash off the dirt accumulated on the inner walls and corners of the reactor 1 and the tower 3, Then, it is dried at room temperature to prevent the dirt accumulated on the inner walls and corners of the reactor 1 and tower 3 from participating in or hindering the progress of the reaction, mixing impurities, and affecting the yield of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com