Waste gas purification treatment method

A treatment method and exhaust gas purification technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as toxicity and surrounding environmental pollution, and achieve the effects of improved degradation ability, simple equipment, and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

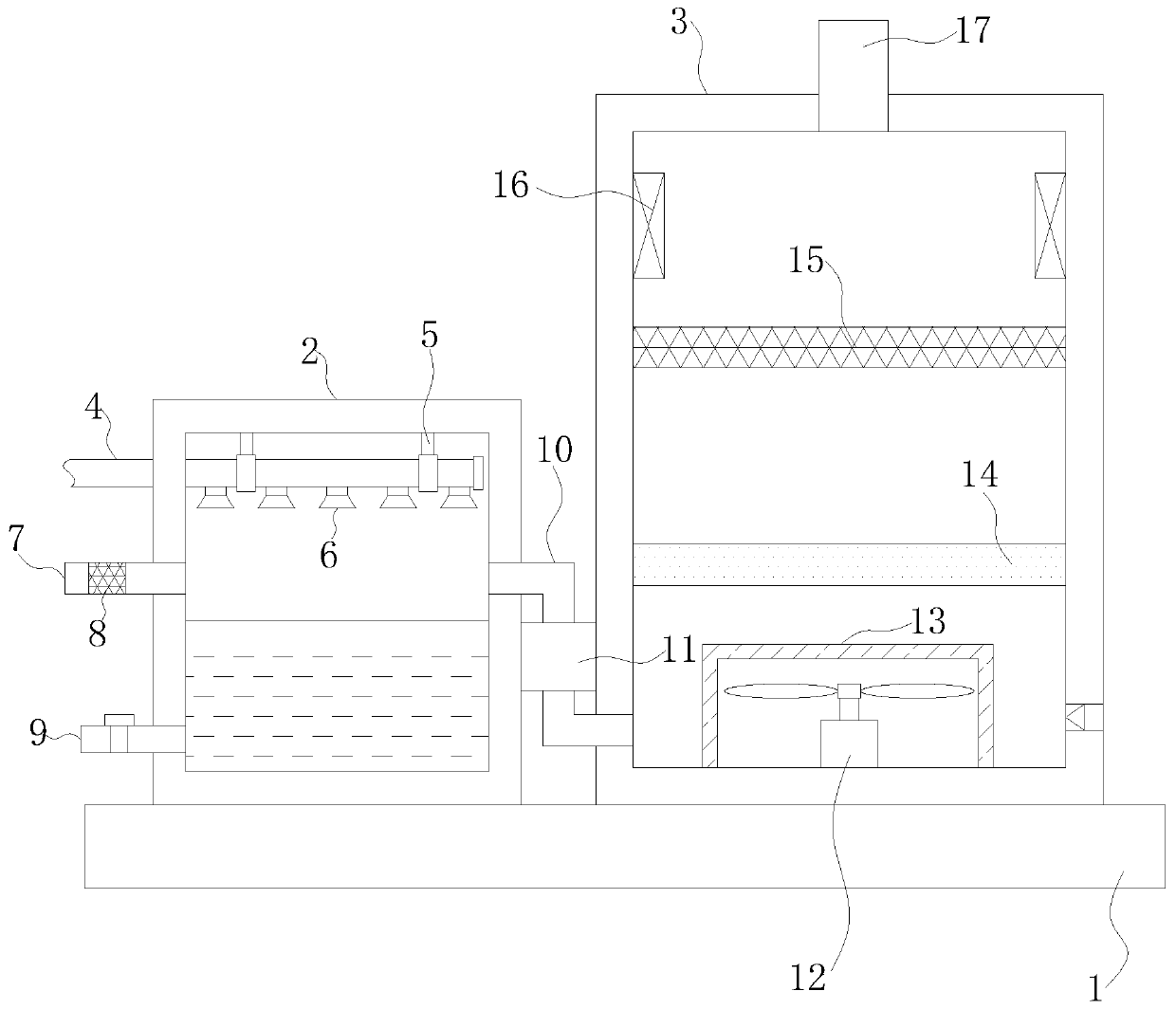

[0033] Such as Figure 1-2 As shown, the present invention provides a technical solution: the exhaust gas purification treatment method is completed by the exhaust gas treatment equipment, which specifically includes the following steps:

[0034] S1. Connect the water source to the water inlet pipe 4, so that the water is sprayed from the atomizing nozzle 6, and the water is sprayed from the atomizing nozzle 6 at 360°, so that the atomizing nozzle 6 can spray the exhaust gas more evenly and fully.

[0035] S2. Introduce waste gas, perform humidification and spray treatment on the waste gas, and spray for 5 minutes. Before the waste gas is sprayed, the large particles of dust are filtered by the filter screen 18.

[0036] S3, start the induced draft fan 11 and the blower 12, and send the gas in S2 to the bottom of the processing chamber 3.

[0037] S4. The exhaust gas moves from bottom to top in the treatment chamber 3, and is preliminarily filtered through the filter material...

Embodiment 2

[0043] Such as Figure 1-2 As shown, the present invention provides a technical solution: a waste gas purification treatment method, the waste gas purification treatment method is completed by waste gas treatment equipment, specifically including the following steps:

[0044] S1. Connect the water source to the water inlet pipe 4, so that the water is sprayed from the atomizing nozzle 6, and the water is sprayed from the atomizing nozzle 6 at 360°, so that the atomizing nozzle 6 can spray the exhaust gas more evenly and fully.

[0045]S2. The waste gas is fed in, and the waste gas is humidified and sprayed for 7 minutes. Before the waste gas is sprayed, the large particles of dust are filtered by the filter 8.

[0046] S3, start the induced draft fan 11 and the blower 12, and send the gas in S2 to the bottom of the processing chamber 3.

[0047] S4. The exhaust gas moves from bottom to top in the treatment chamber 3, and is preliminarily filtered through the filter material p...

Embodiment 3

[0053] Such as Figure 1-2 As shown, the present invention provides a technical solution: a waste gas purification treatment method, the waste gas purification treatment method is completed by waste gas treatment equipment, specifically including the following steps:

[0054] S1. Connect the water source to the water inlet pipe 4, so that the water is sprayed from the atomizing nozzle 6, and the water is sprayed from the atomizing nozzle 6 at 360°, so that the atomizing nozzle 6 can spray the exhaust gas more evenly and fully.

[0055] S2. Introduce waste gas, perform humidification and spray treatment on the waste gas, and spray for 10 minutes, before the waste gas is sprayed, the large particles of dust are filtered by the filter screen 18.

[0056] S3, start the induced draft fan 11 and the blower 12, and send the gas in S2 to the bottom of the processing chamber 3.

[0057] S4. The exhaust gas moves from bottom to top in the treatment chamber 3, and is preliminarily filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com