A breeding waste gas treatment device

The technology of a waste gas treatment device and an air duct is applied in the directions of gas treatment, separation method, dispersed particle separation, etc., and can solve the problems of environmental hazards, poor waste gas treatment effect, and inability to purify waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

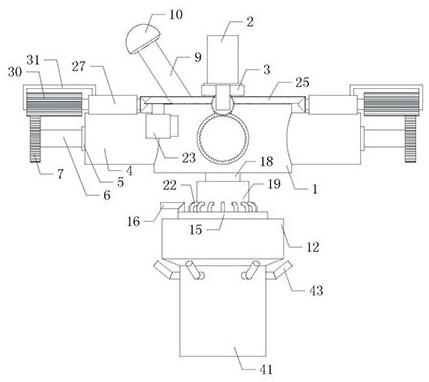

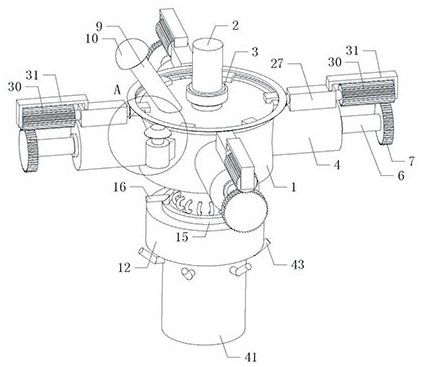

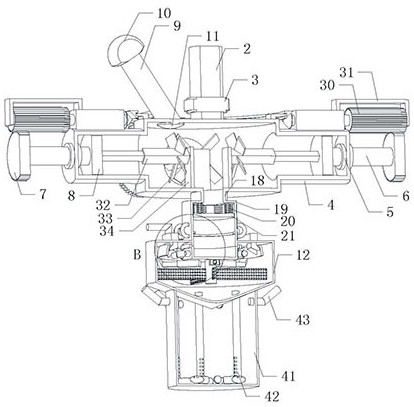

[0018] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

[0019] like Figure 1 to Figure 5 As shown in the figure, a culture waste gas treatment device of the present invention, when it is working, the outside sunlight shines on the spherical light-absorbing glass 10, and the sunlight passes through the outer wall of the spherical light-absorbing glass 10 and enters the spherical light-absorbing glass 10 and is transmitted to the light guide tube 9. , because the spherical light-absorbing glass 10 is spherical in shape, it is convenient to make the sunlight at different times always irradiate on the spherical light-absorbing glass 10, and at the same time, the spherical light-absorbing glass 10 can gather the sunlight absorbed by its surface, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com